WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,198

Only one picture, I have to get some some stuff moved around and get it ready to go where my YA M60 24" planer was.

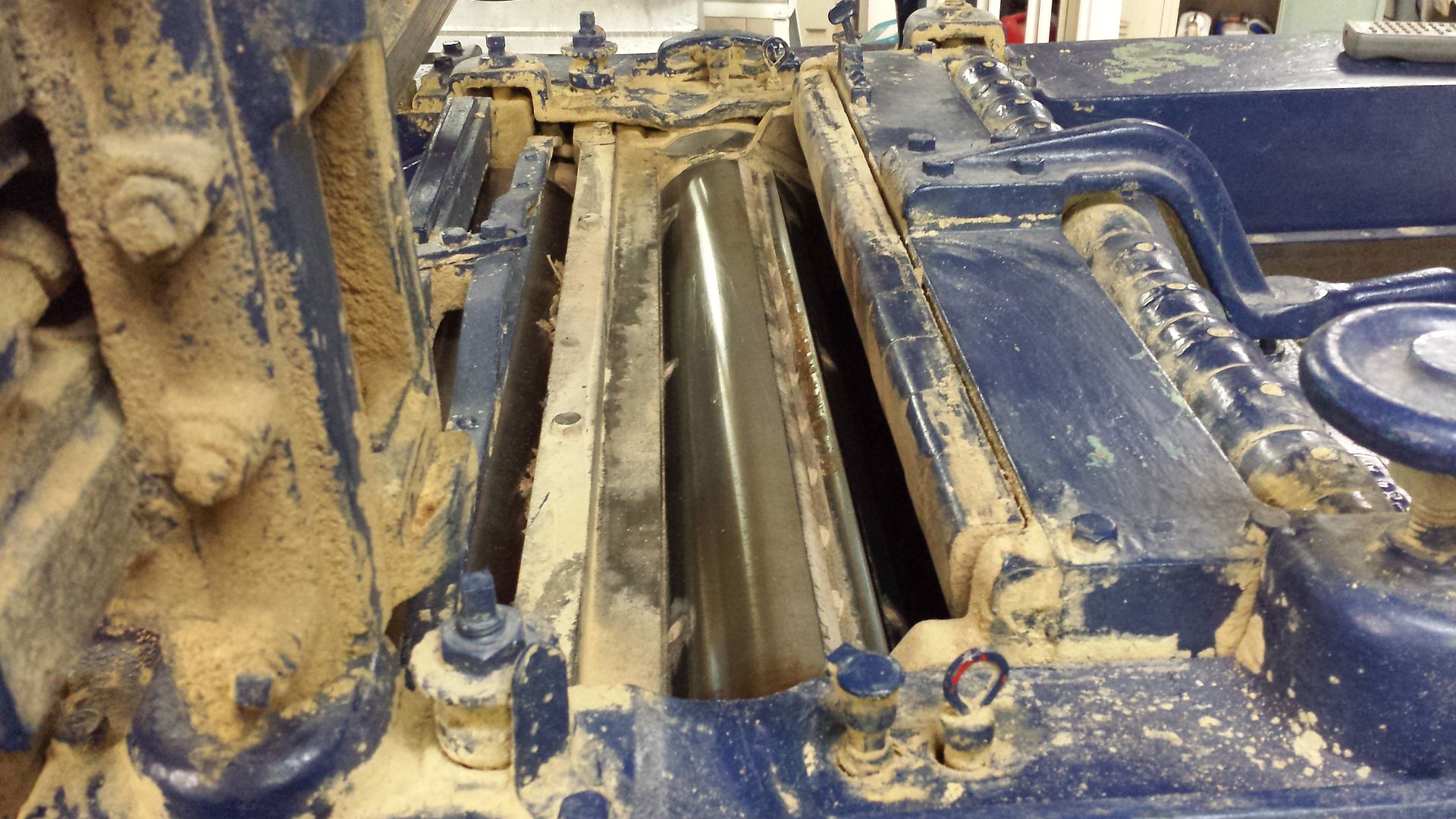

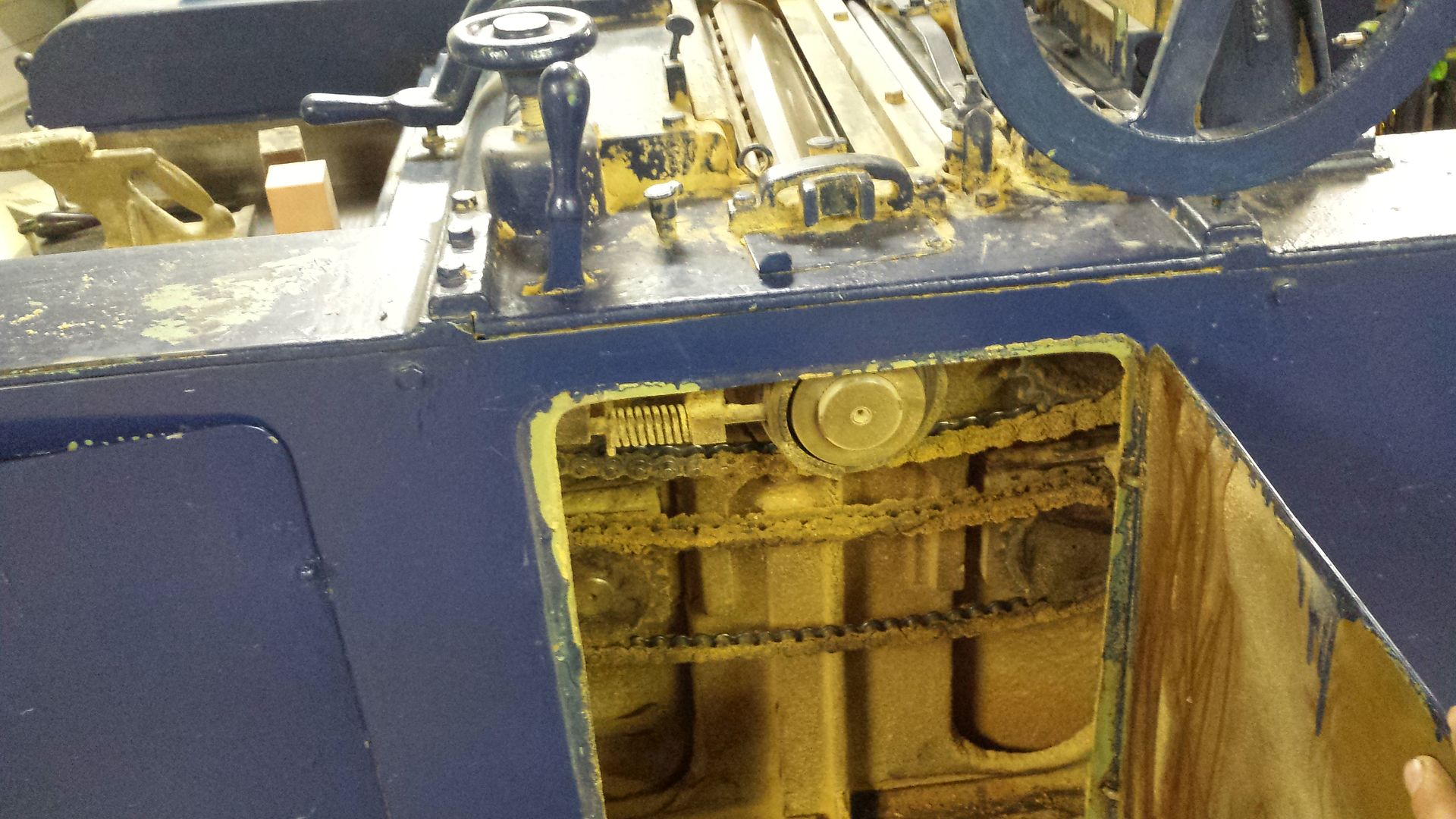

I think the planer came from Warner Swasey's pattern shop and was made in 1944, I think.

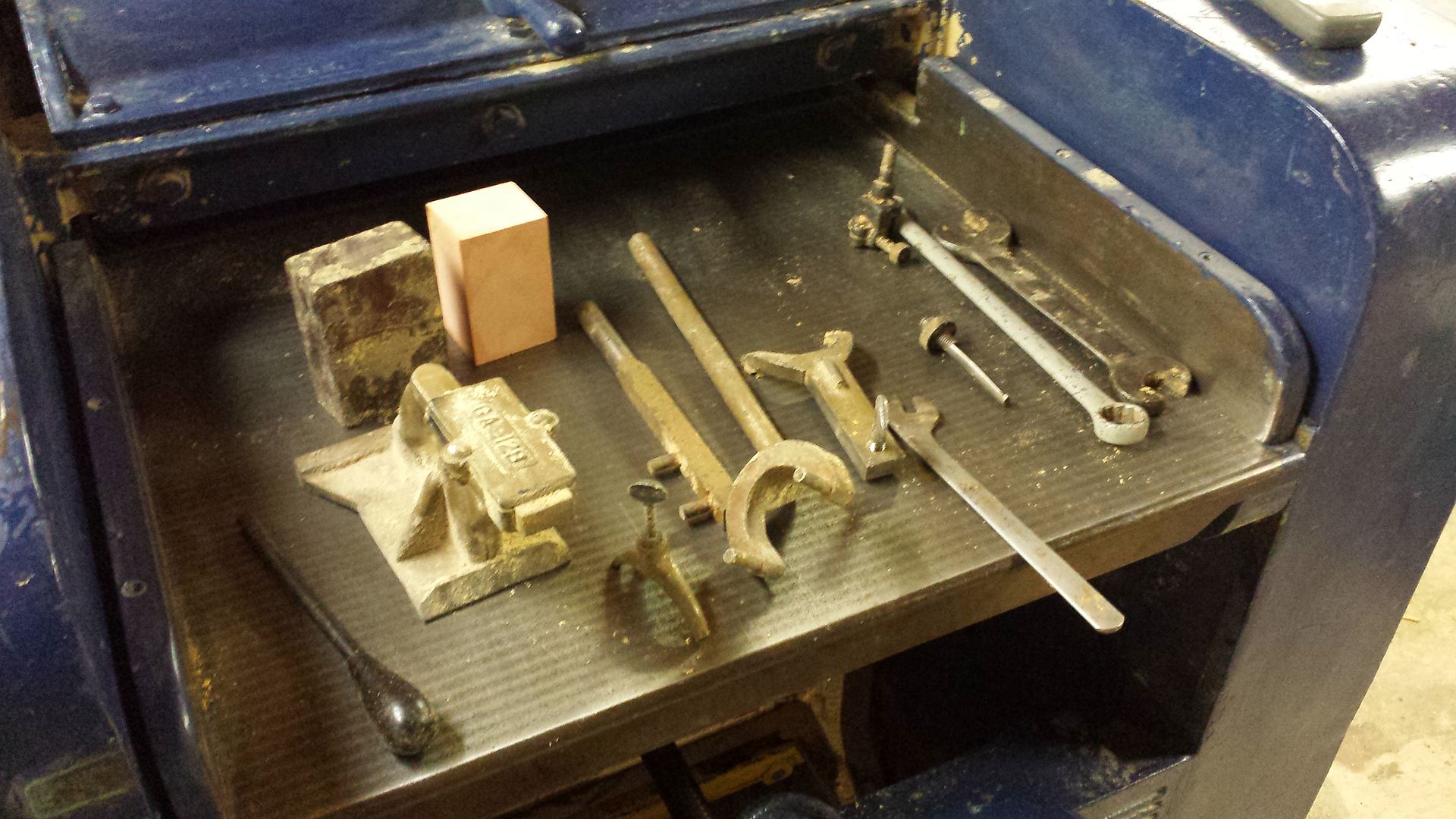

I am also sure it has every accessory that ever came with one from Buss.

I think the lift operator had already been kicking some back today.....

I think the planer came from Warner Swasey's pattern shop and was made in 1944, I think.

I am also sure it has every accessory that ever came with one from Buss.

I think the lift operator had already been kicking some back today.....