Hi Festool owners,

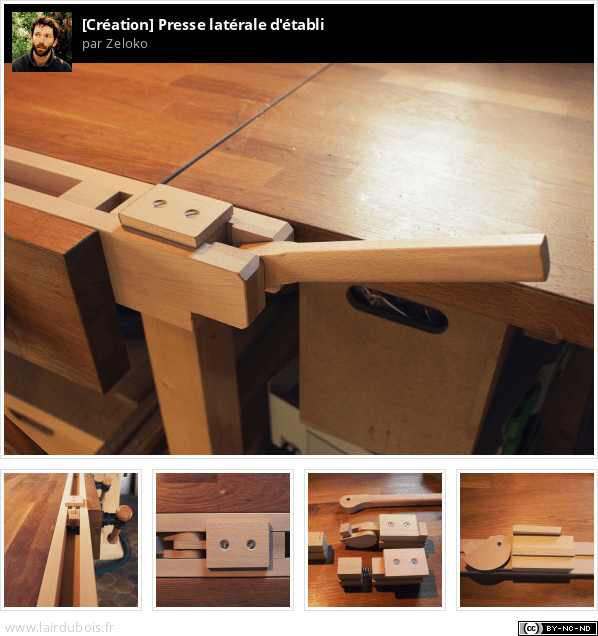

The Rotex is a good tool for sanding, but it is not possible to use it if you don't clamp the piece you want to sand.

In Festool accessories univers, there's a lot of way to do this, but sometimes it's good to build our own tools. Then I imagine this clamping system.

Maybe it can interest someone here. And in this case, you can download the plan on L'Air du Bois (a french woodworkers community).

This projet was inspired by a previous clamping system for Domino.

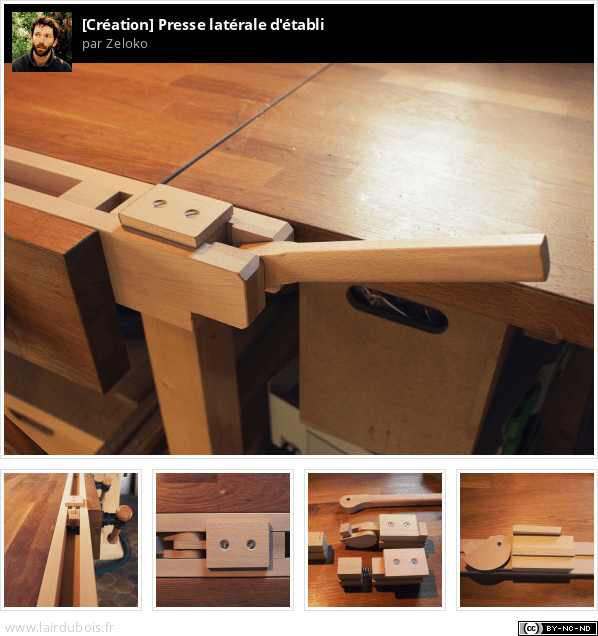

The Rotex is a good tool for sanding, but it is not possible to use it if you don't clamp the piece you want to sand.

In Festool accessories univers, there's a lot of way to do this, but sometimes it's good to build our own tools. Then I imagine this clamping system.

Maybe it can interest someone here. And in this case, you can download the plan on L'Air du Bois (a french woodworkers community).

This projet was inspired by a previous clamping system for Domino.