Richard/RMW

Member

- Joined

- Jul 11, 2010

- Messages

- 2,947

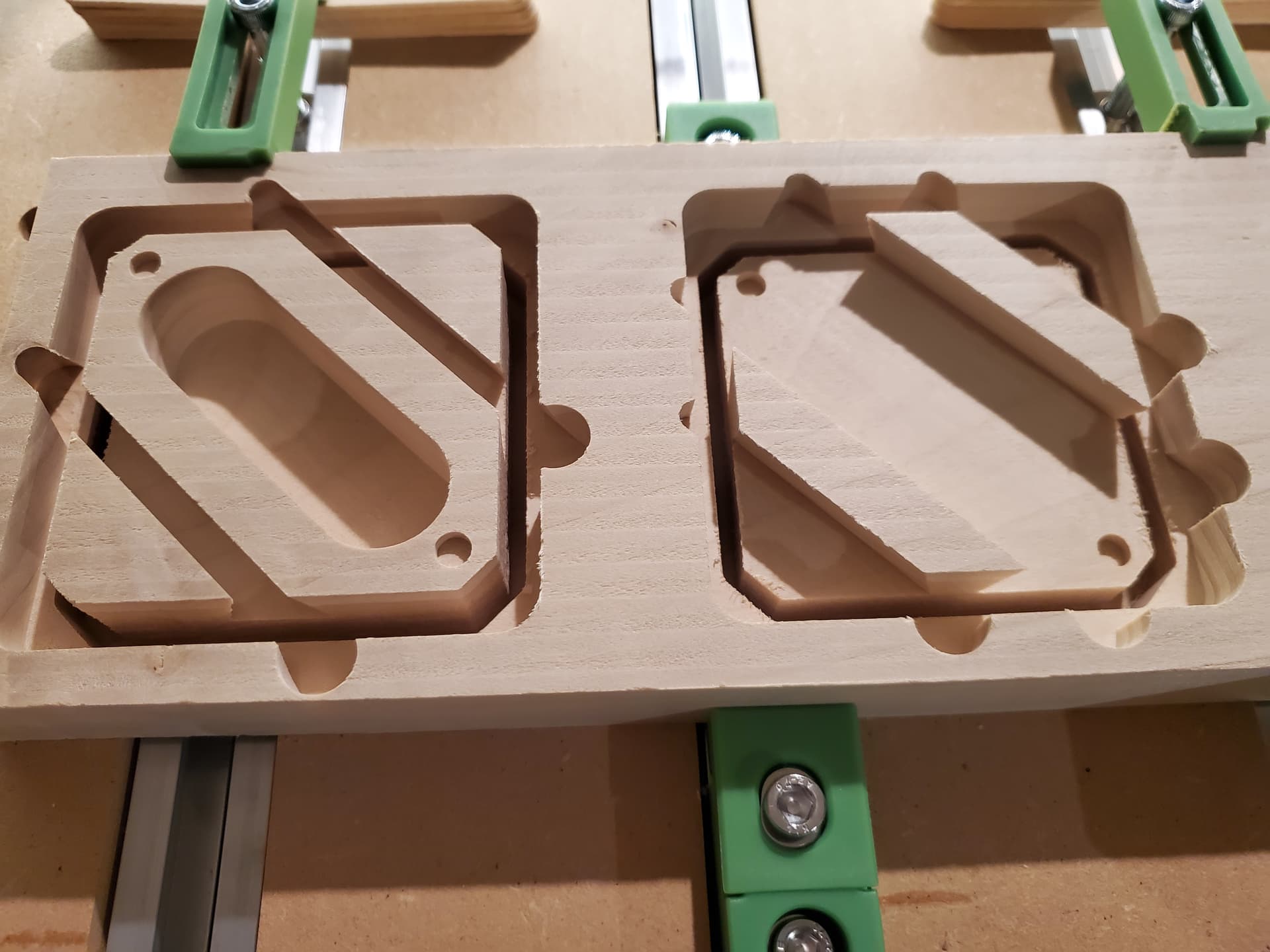

The video is unrelated to woodworking however it struck me that we may be reaching a point where automated workshop machines and processes are within the grasp of many more small businesses. The setup process is the important aspect IMO.

This machine let's a small business hire unskilled labor and have them be productive immediately, just loading/unloading the machine after an hour of training. Also changing setups to run different operations should take minutes. It's brilliant.

What are the analogous situations in a small woodworking business?

RMW

This machine let's a small business hire unskilled labor and have them be productive immediately, just loading/unloading the machine after an hour of training. Also changing setups to run different operations should take minutes. It's brilliant.

What are the analogous situations in a small woodworking business?

RMW