i realize the cms is not available in the u.s. yet. but i think this is a common problem for anyone using a table saw.

i was using the cms ts-75 table saw yesterday to rip facia board.

i had to rip 15mm off one edge. there was another carpenter helping me, but it was difficult to keep the timber tight against the fence.

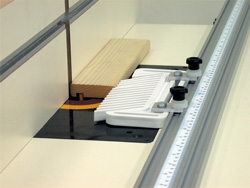

a feather board would have been great.

is there a festool feather board available?

can anybody recommend an after market brand?

bearing in mind that the table saw is made from aluminium. so a magnetic feather board will not work.

thanks in advance, justin.

i was using the cms ts-75 table saw yesterday to rip facia board.

i had to rip 15mm off one edge. there was another carpenter helping me, but it was difficult to keep the timber tight against the fence.

a feather board would have been great.

is there a festool feather board available?

can anybody recommend an after market brand?

bearing in mind that the table saw is made from aluminium. so a magnetic feather board will not work.

thanks in advance, justin.