This may not be of great interest here, particularly since the Kapex is known for its excellent dust collection, but a Kapex is not in my future plans. The DeWalt DW716 does what I need and I've used it either hooked up to a shop vac or use the bag that came with it. A lot of my cutting has been outside or in the garage and dust collection isn't this miter saw's strength. It's terrible at DC and spews sawdust everywhere.

Now that I've got a basement shop and a Jet Cyclone dust collector, I've proceeded to put Rockler Dust Right connectors on each tool and simply move the hose from one tool to another. The shop is too small for dedicated piping since the tools need to be moved around for use. So far, so good with collecting dust with the exception of the DeWalt which dumps sawdust everywhere. I don't have a miter saw station for it, so its set up on its portable stand.

In the past I've tried cardboard, foam, canvas, etc. to fabricate a dust collector for this saw, all resulting in failure. Not being one to give up and wanting a clean shop I came up with this a few days ago. All made from leftovers from previous projects so no big deal if this turned out to be another failed experiment.

Stage 1: A box of some sort behind, under and to the sides of the saw. The biggest issue in the past was how to attach something to the DeWalt. The angled sides are from some triangular leftovers from the basement closet project I built for my wife a few years ago.

Attached with wing nuts to the base of the saw -

Without having cut the hole for the DC port, the first test cut of a 2x4 resulted in a face full of dust, but that was to be expected. At least there wasn't a lot being dumped on the floor.

Stage 2: A trip to Rockler in Salem NH for some materials, rather than waiting for them to arrive by mail. I hadn't been to this store before and it's fun to browse. I did wind up buying some Bessey K clamps.

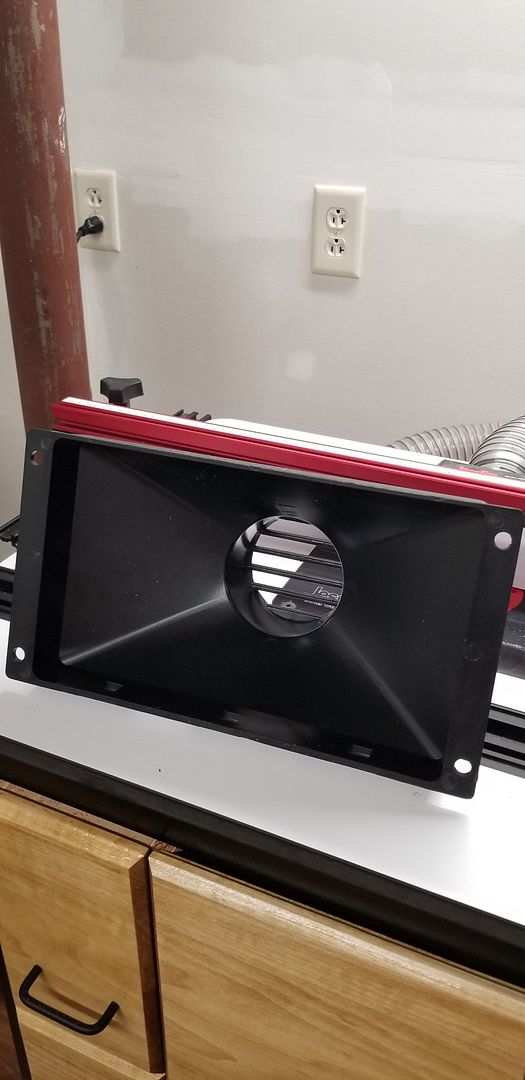

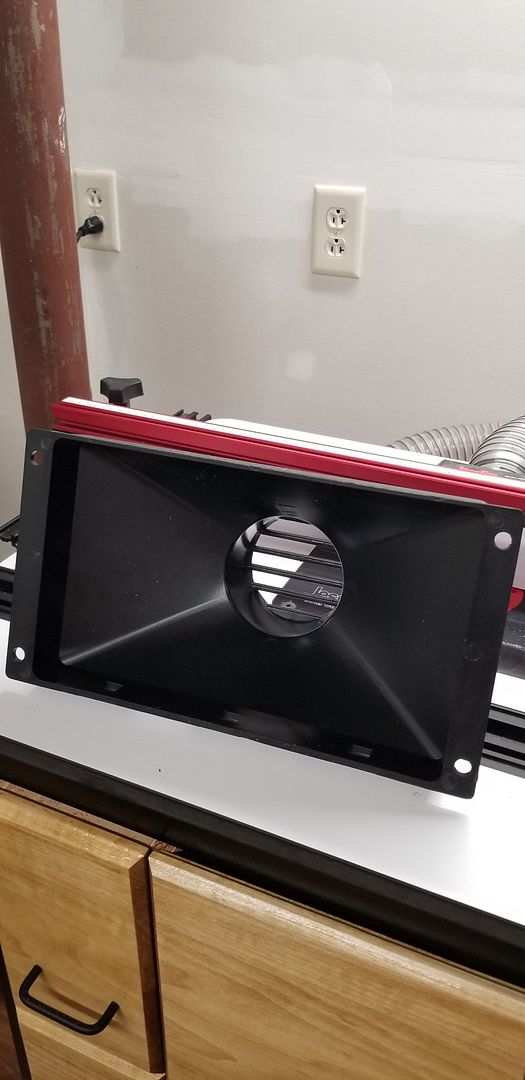

Cut the 4" diameter hole and install a Dust Right connector hooked up to the Jet. Here's a picture of the Dust Collector -

Much better results, but I'm still getting a circulation in the box and dust is escaping out the sides. The sides being angled are great for beveled and miter cuts but for the most part my cuts are at 90 degrees. What to do?

Stage 3: Add movable sides to make more of an enclosed space. Pulled forward and up to the fence -

and slid back if needed -

Stage 4: I'm still getting somewhat of a circulation at the top of the box, so I added this, which simply rests in place and is easily removed for angled cuts -

It resolves the issue of dust escaping out the top, so that was an easy fix. The center cutout allows the saw to be raised.

Future Plans: I'll see how the simple 4" port works. There's a lot of dust left in the box, but at least it's contained. I can either brush it towards the port or vacuum it out afterwards. I may opt to install this which I picked up at Rockler -

And that's it. A problem that has been plaguing me since purchasing this saw and for the most part solved. With the exception of the parts purchased at Rockler, all fabricated from scraps.

Thanks for checking out this post.

Regards,

-Dom

Now that I've got a basement shop and a Jet Cyclone dust collector, I've proceeded to put Rockler Dust Right connectors on each tool and simply move the hose from one tool to another. The shop is too small for dedicated piping since the tools need to be moved around for use. So far, so good with collecting dust with the exception of the DeWalt which dumps sawdust everywhere. I don't have a miter saw station for it, so its set up on its portable stand.

In the past I've tried cardboard, foam, canvas, etc. to fabricate a dust collector for this saw, all resulting in failure. Not being one to give up and wanting a clean shop I came up with this a few days ago. All made from leftovers from previous projects so no big deal if this turned out to be another failed experiment.

Stage 1: A box of some sort behind, under and to the sides of the saw. The biggest issue in the past was how to attach something to the DeWalt. The angled sides are from some triangular leftovers from the basement closet project I built for my wife a few years ago.

Attached with wing nuts to the base of the saw -

Without having cut the hole for the DC port, the first test cut of a 2x4 resulted in a face full of dust, but that was to be expected. At least there wasn't a lot being dumped on the floor.

Stage 2: A trip to Rockler in Salem NH for some materials, rather than waiting for them to arrive by mail. I hadn't been to this store before and it's fun to browse. I did wind up buying some Bessey K clamps.

Cut the 4" diameter hole and install a Dust Right connector hooked up to the Jet. Here's a picture of the Dust Collector -

Much better results, but I'm still getting a circulation in the box and dust is escaping out the sides. The sides being angled are great for beveled and miter cuts but for the most part my cuts are at 90 degrees. What to do?

Stage 3: Add movable sides to make more of an enclosed space. Pulled forward and up to the fence -

and slid back if needed -

Stage 4: I'm still getting somewhat of a circulation at the top of the box, so I added this, which simply rests in place and is easily removed for angled cuts -

It resolves the issue of dust escaping out the top, so that was an easy fix. The center cutout allows the saw to be raised.

Future Plans: I'll see how the simple 4" port works. There's a lot of dust left in the box, but at least it's contained. I can either brush it towards the port or vacuum it out afterwards. I may opt to install this which I picked up at Rockler -

And that's it. A problem that has been plaguing me since purchasing this saw and for the most part solved. With the exception of the parts purchased at Rockler, all fabricated from scraps.

Thanks for checking out this post.

Regards,

-Dom