Steven Owen

Member

- Joined

- Oct 4, 2017

- Messages

- 443

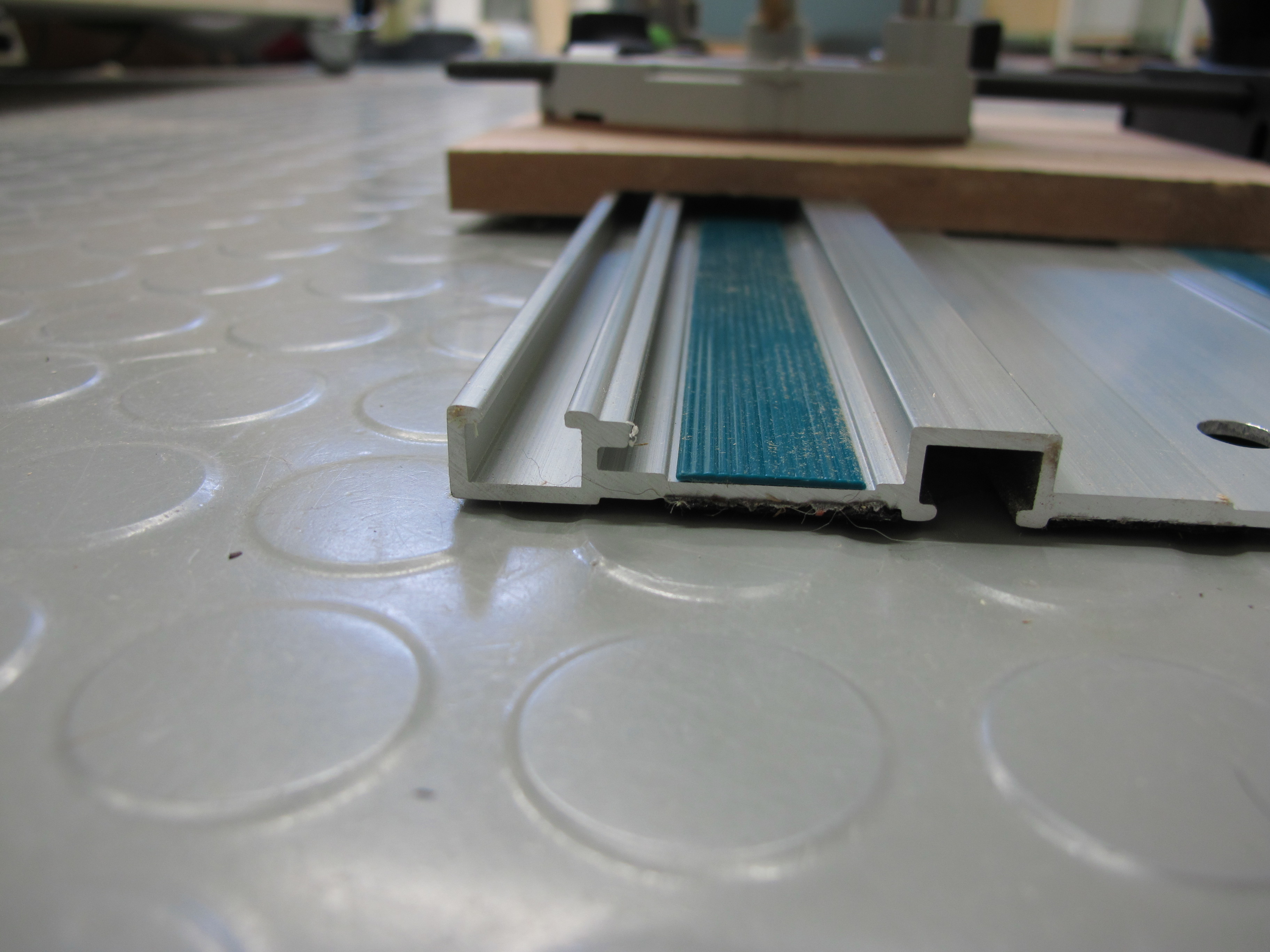

Has anyone ever tried using their Festool router and track guide stop with the other vendors tracks?

Makita and Triton have rails that mirror most of the design elements of the Festool rails. Do you know if the accessory guide stop for the OF 1400 will work on Triton’s or Makita’s rails?

Makita and Triton have rails that mirror most of the design elements of the Festool rails. Do you know if the accessory guide stop for the OF 1400 will work on Triton’s or Makita’s rails?