Hi,

In a current projet I would like to use this kind of joinery to build boxes under a desk :

I would cut the bevel on panels with my TS55 plunge saw.

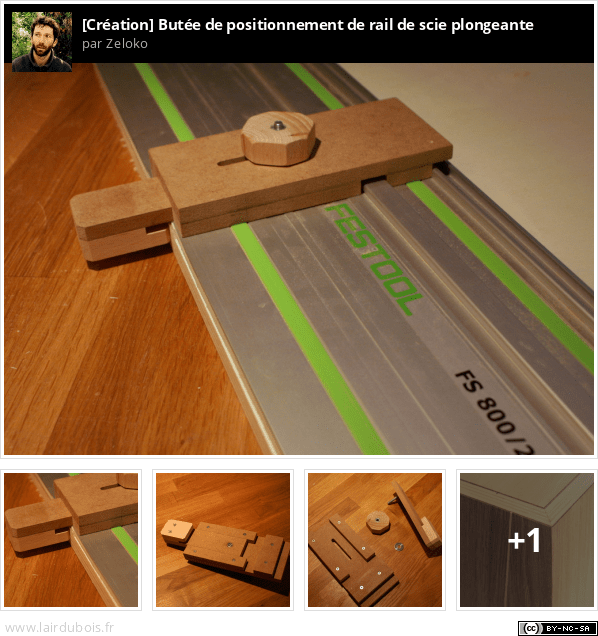

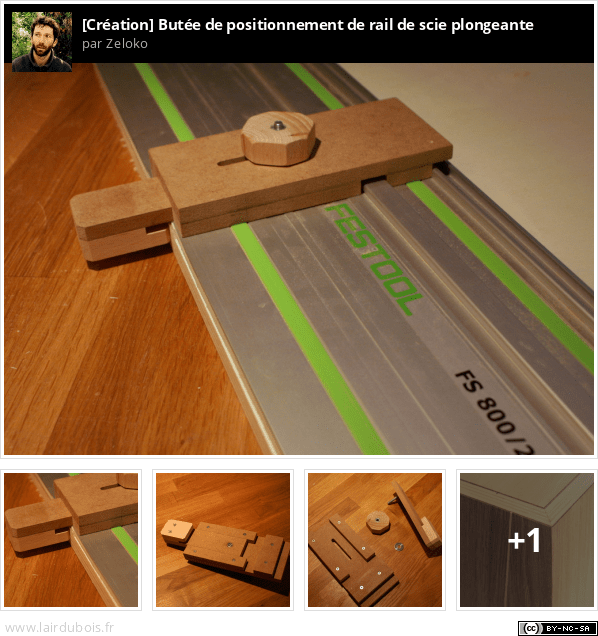

But, in order to cut them, I build a small jig to place correctly my FS plunge saw rail.

This jig permit a first cut at 90° with the table saw and after cut the 45° bevel with the plunge saw without changing the panel width.

You can view it in action in this video. But sorry, it's in French.

In a current projet I would like to use this kind of joinery to build boxes under a desk :

I would cut the bevel on panels with my TS55 plunge saw.

But, in order to cut them, I build a small jig to place correctly my FS plunge saw rail.

This jig permit a first cut at 90° with the table saw and after cut the 45° bevel with the plunge saw without changing the panel width.

You can view it in action in this video. But sorry, it's in French.