Guys,

I want to make some shelves which will be solid wood pieces laminated to each other but with the twist that they will have aluminum inbetween.

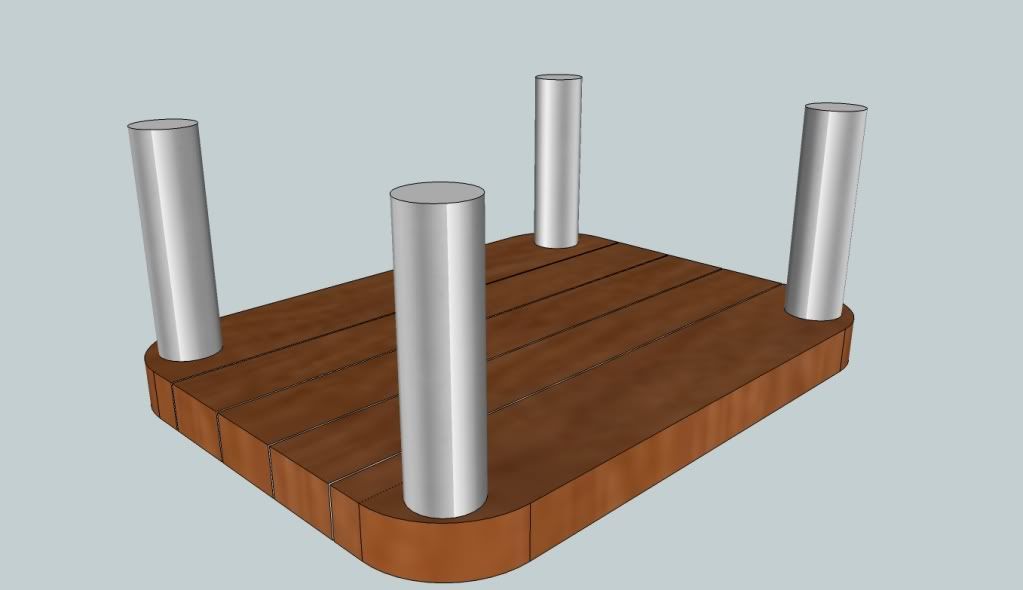

Here is a quick sketchup image to give you an idea of what I am talking about:

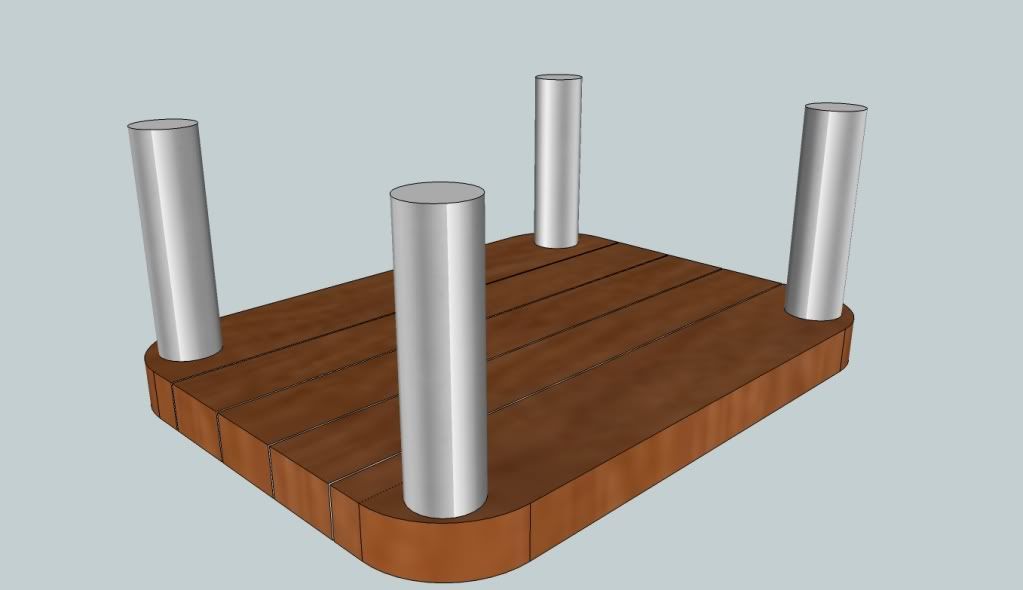

The finish and look I am going for is something like this:

And was thinking a Danish oil finish. I do have a RO150 and was wondering about the sanding/oiling steps/grits? I already determined I need a hard pad to keep the shelf flat since the standard pad is wearing the wood down faster than the aluminum.

Just now read up a bit on the festool vlies and was thinking about using them in the final finishing. How does one prevent the endgrain going much darker?

Any other suggestion would really be appreciated.

I want to make some shelves which will be solid wood pieces laminated to each other but with the twist that they will have aluminum inbetween.

Here is a quick sketchup image to give you an idea of what I am talking about:

The finish and look I am going for is something like this:

And was thinking a Danish oil finish. I do have a RO150 and was wondering about the sanding/oiling steps/grits? I already determined I need a hard pad to keep the shelf flat since the standard pad is wearing the wood down faster than the aluminum.

Just now read up a bit on the festool vlies and was thinking about using them in the final finishing. How does one prevent the endgrain going much darker?

Any other suggestion would really be appreciated.