quick Q for you guys

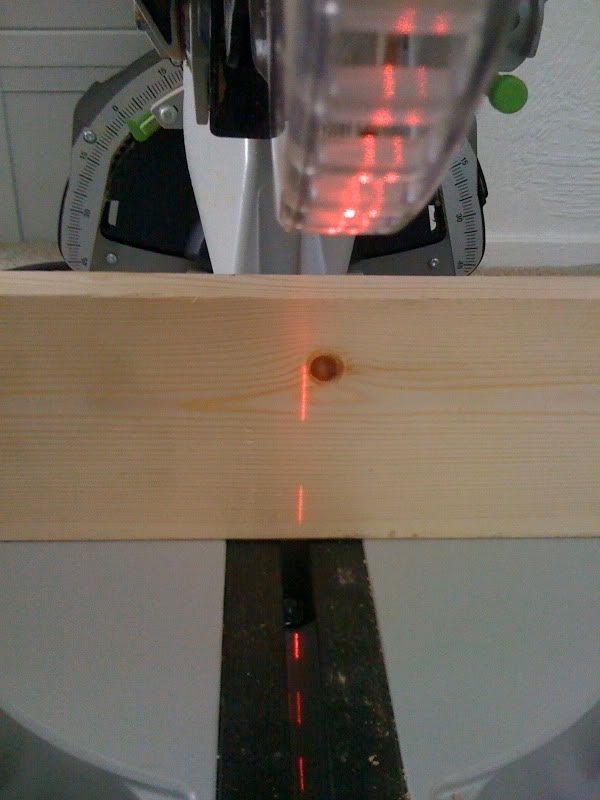

when cutting in the special position my left laser only shows on the first 1" up the 4x1 , the right hand laser goes all way up but dont go over the top, is this normal?

if i want to cut a exact measure between 2 longpoints in having to relise the special cutting lever. set the cut up with the laser clamp then re engage the special cutting. is there any adjustments

when cutting in the special position my left laser only shows on the first 1" up the 4x1 , the right hand laser goes all way up but dont go over the top, is this normal?

if i want to cut a exact measure between 2 longpoints in having to relise the special cutting lever. set the cut up with the laser clamp then re engage the special cutting. is there any adjustments