Floorman70

Member

- Joined

- Oct 21, 2011

- Messages

- 72

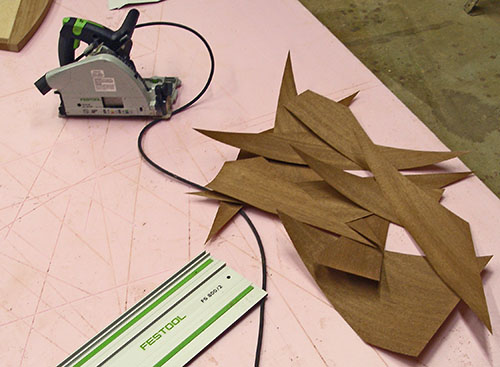

Occasionally i go to a small job,where it`s not worth taking in benches etc. or there is no room to set up where i am working.I always carry 2 pieces of 4ftx2ft 18mm mdf,backed with self adhesive foam flooring underlay,this gives me a work surface on the floor that i can put my workpiece on and cut through with the ts,without risking cutting the floor,the foam underlay on the back stops them sliding about and marking the floor and they don`t take up any space in the van