I am just a hobbiest and purchased my MFT as part of a router system I wanted. My first project on it was a speargun I made from a reclaimed teak swim platform. This was a fun project and came out nice. I took my time, about 6 months or so...I have since built a few more guns that fellow divers wanted after using my gun.

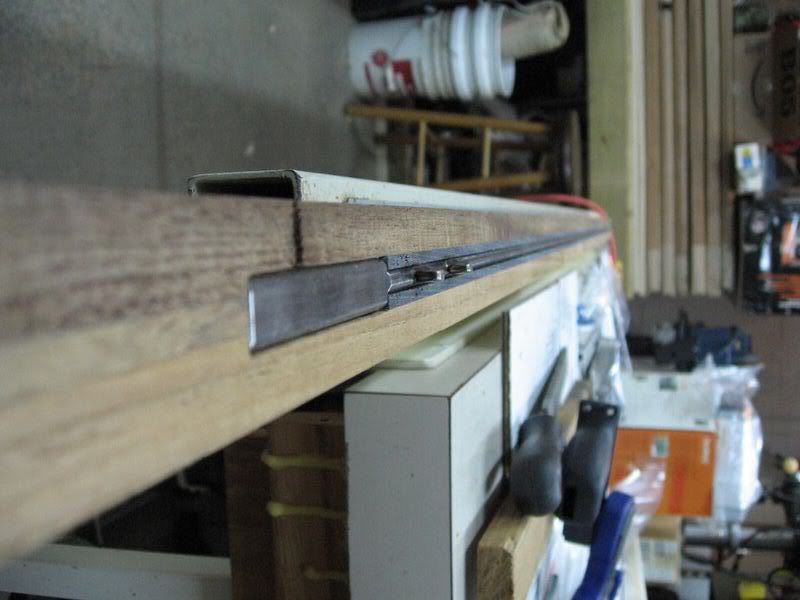

The old platform from my Formula 357 boat.

Finished Speargun.

The old platform from my Formula 357 boat.

Finished Speargun.