- Joined

- Jan 22, 2007

- Messages

- 1,641

Phil,

I wouldn't hesitate to get these voltage readings before installing this startup kit. I have never seen a rotary converter that needed a startup kit for the tools. Its mere existence implies that the converter isn't doing its job in the first place.

With the exception of the dust collector that is failing to reach running speed, you are not going to damage the tool motors by running them at no-load in order to take these measurements. Just avoid excessive back-to-back restarts and don't leave them running for a long time.

If you have already taken some of these measurements, then tell me what they were. The more information I have, the better I can help you diagnose the problem. I also want to avoid putting a bandaid on something that winds up masking the true problem.

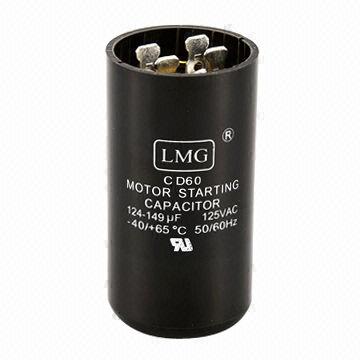

I'm a little concerned that this "startup kit" is nothing more than a static phase converter, and putting it on the motor will simply mask the true problem.

I wouldn't hesitate to get these voltage readings before installing this startup kit. I have never seen a rotary converter that needed a startup kit for the tools. Its mere existence implies that the converter isn't doing its job in the first place.

With the exception of the dust collector that is failing to reach running speed, you are not going to damage the tool motors by running them at no-load in order to take these measurements. Just avoid excessive back-to-back restarts and don't leave them running for a long time.

If you have already taken some of these measurements, then tell me what they were. The more information I have, the better I can help you diagnose the problem. I also want to avoid putting a bandaid on something that winds up masking the true problem.

I'm a little concerned that this "startup kit" is nothing more than a static phase converter, and putting it on the motor will simply mask the true problem.