six-point socket II

Member

- Joined

- Jun 26, 2016

- Messages

- 2,237

Hi everyone!

A little over 6 years ago I had to repair and partly replace an electrical line coming from our basement feeding the garden & sheds.

Initially I wanted to replace the whole line, but that wasn't an option 6 years ago because I couldn't get the access needed for that. At least not within a feasible amount of time and without a lot of additional work afterwards.

So I opted to replace only a part of the line and repair the joint. I chose BBC Cellpack's "Easycell(R)" gel-technology straight-joint boxes for that repair. They come as box pre-packed with gel and a connector terminal. ->https://electricalproducts.cellpack.com/en/gel-technology/easycell/

They also now have an incredible gel-technology product line suiting the Wago 221 line of connectors that we all love. ->https://electricalproducts.cellpack.com/en/gel-technology/easy-protect/

This year was packed with many major refurbishment projects & one of them finally got me the access needed to replace the whole line. So it was a no-brainer to do it. That then lead to the interesting chance of taking out the Easycell(R) boxes and have a closer look at them after being buried and used for roughly 6 years.

When I buried them I did cover them just in case and for visibility if I had to dig again in that area - that cover removed they look pretty clean & sound.

[attachimg=1]

Cut out & on the table.

[attachimg=2]

Sideview. The gel neatly enclosed the cable. (1 picture, looked exactly the same on the remaining 3 sides)

[attachimg=3]

Let's open them.

Box 1

[attachimg=4]

[attachimg=5]

Box 2

[attachimg=6]

[attachimg=7]

As you can see, the cables & connectors are in absolute pristine condition. I was honestly impressed how well that worked - not to mention that over the 6 years we didn't have a single failure/issue with the garden & shed electrics.

Bonus:

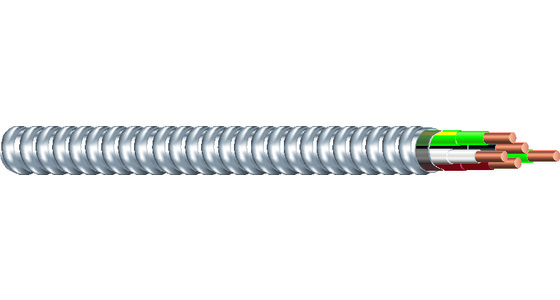

I said before that I wanted to replace the whole line, and I did. And I did find what I expected speaking of the - until then not replaced - part. So here's the part (of the original line/cable) that I couldn't replace the first time I was working on this. It came out the conduit exactly like this. Since that was way oversized, my guess is some varmint (or whatever) had a go at it. Or the pre-owner damaged it while pulling it originally. It did hold up to an insulation resistance test at 250V back then, my guess is that 500V would have come back negative/ failed. When I thought of this, I sadly had already disposed of all the trash, so I couldn't do the experiment.

[attachimg=8]

[attachimg=9]

[attachimg=10]

Kind regards,

Oliver

A little over 6 years ago I had to repair and partly replace an electrical line coming from our basement feeding the garden & sheds.

Initially I wanted to replace the whole line, but that wasn't an option 6 years ago because I couldn't get the access needed for that. At least not within a feasible amount of time and without a lot of additional work afterwards.

So I opted to replace only a part of the line and repair the joint. I chose BBC Cellpack's "Easycell(R)" gel-technology straight-joint boxes for that repair. They come as box pre-packed with gel and a connector terminal. ->https://electricalproducts.cellpack.com/en/gel-technology/easycell/

They also now have an incredible gel-technology product line suiting the Wago 221 line of connectors that we all love. ->https://electricalproducts.cellpack.com/en/gel-technology/easy-protect/

This year was packed with many major refurbishment projects & one of them finally got me the access needed to replace the whole line. So it was a no-brainer to do it. That then lead to the interesting chance of taking out the Easycell(R) boxes and have a closer look at them after being buried and used for roughly 6 years.

When I buried them I did cover them just in case and for visibility if I had to dig again in that area - that cover removed they look pretty clean & sound.

[attachimg=1]

Cut out & on the table.

[attachimg=2]

Sideview. The gel neatly enclosed the cable. (1 picture, looked exactly the same on the remaining 3 sides)

[attachimg=3]

Let's open them.

Box 1

[attachimg=4]

[attachimg=5]

Box 2

[attachimg=6]

[attachimg=7]

As you can see, the cables & connectors are in absolute pristine condition. I was honestly impressed how well that worked - not to mention that over the 6 years we didn't have a single failure/issue with the garden & shed electrics.

Bonus:

I said before that I wanted to replace the whole line, and I did. And I did find what I expected speaking of the - until then not replaced - part. So here's the part (of the original line/cable) that I couldn't replace the first time I was working on this. It came out the conduit exactly like this. Since that was way oversized, my guess is some varmint (or whatever) had a go at it. Or the pre-owner damaged it while pulling it originally. It did hold up to an insulation resistance test at 250V back then, my guess is that 500V would have come back negative/ failed. When I thought of this, I sadly had already disposed of all the trash, so I couldn't do the experiment.

[attachimg=8]

[attachimg=9]

[attachimg=10]

Kind regards,

Oliver

Attachments

-

IMG_6808.jpg190 KB · Views: 362

IMG_6808.jpg190 KB · Views: 362 -

IMG_6850.jpg242.6 KB · Views: 338

IMG_6850.jpg242.6 KB · Views: 338 -

IMG_6849.jpg120.3 KB · Views: 323

IMG_6849.jpg120.3 KB · Views: 323 -

IMG_6848.jpg231.7 KB · Views: 328

IMG_6848.jpg231.7 KB · Views: 328 -

IMG_6871.jpg291.1 KB · Views: 326

IMG_6871.jpg291.1 KB · Views: 326 -

IMG_6868.jpg336.6 KB · Views: 329

IMG_6868.jpg336.6 KB · Views: 329 -

IMG_6862.jpg274 KB · Views: 331

IMG_6862.jpg274 KB · Views: 331 -

IMG_6860.jpg299.9 KB · Views: 315

IMG_6860.jpg299.9 KB · Views: 315 -

IMG_6857.jpg217 KB · Views: 356

IMG_6857.jpg217 KB · Views: 356 -

IMG_6852.jpg287.4 KB · Views: 365

IMG_6852.jpg287.4 KB · Views: 365