Taking a break from building cabinets for the wife's master closet and decided to do something I've always wanted to try. Adirondack chairs. I searched the web for plans, many of which are for odd looking Adirondacks. I finally found Norm Abram's plans, a traditional style, and went with those. I drew them out on graph paper, cut them out and transferred the templates to poster board. I also needed to acquire a bandsaw and spindle sander, both bench top models, but they do the trick.

The only modification I made was to the arm width. Norm's plans call for 5" wide arms, but why bother ripping a 5 1/2" board down a half inch? More room for beer bottles.

The wood is Meranti, recommended by the folks at The Woodery in Lunenburg MA. Of course, Adirondack chairs pal around in pairs so as Norm always does, this is the prototype -

It's finished in Watco Teak Oil. All hardware is Stainless Steel.

And some build pics, I didn't take many. The major Festool use was the RO90 with both the round pad and the delta pad, both with 320 Granat. I also used 60 with the delta pad to help take down the plugs. I also made use of the TS55 for the few straight cuts.

Unfinished -

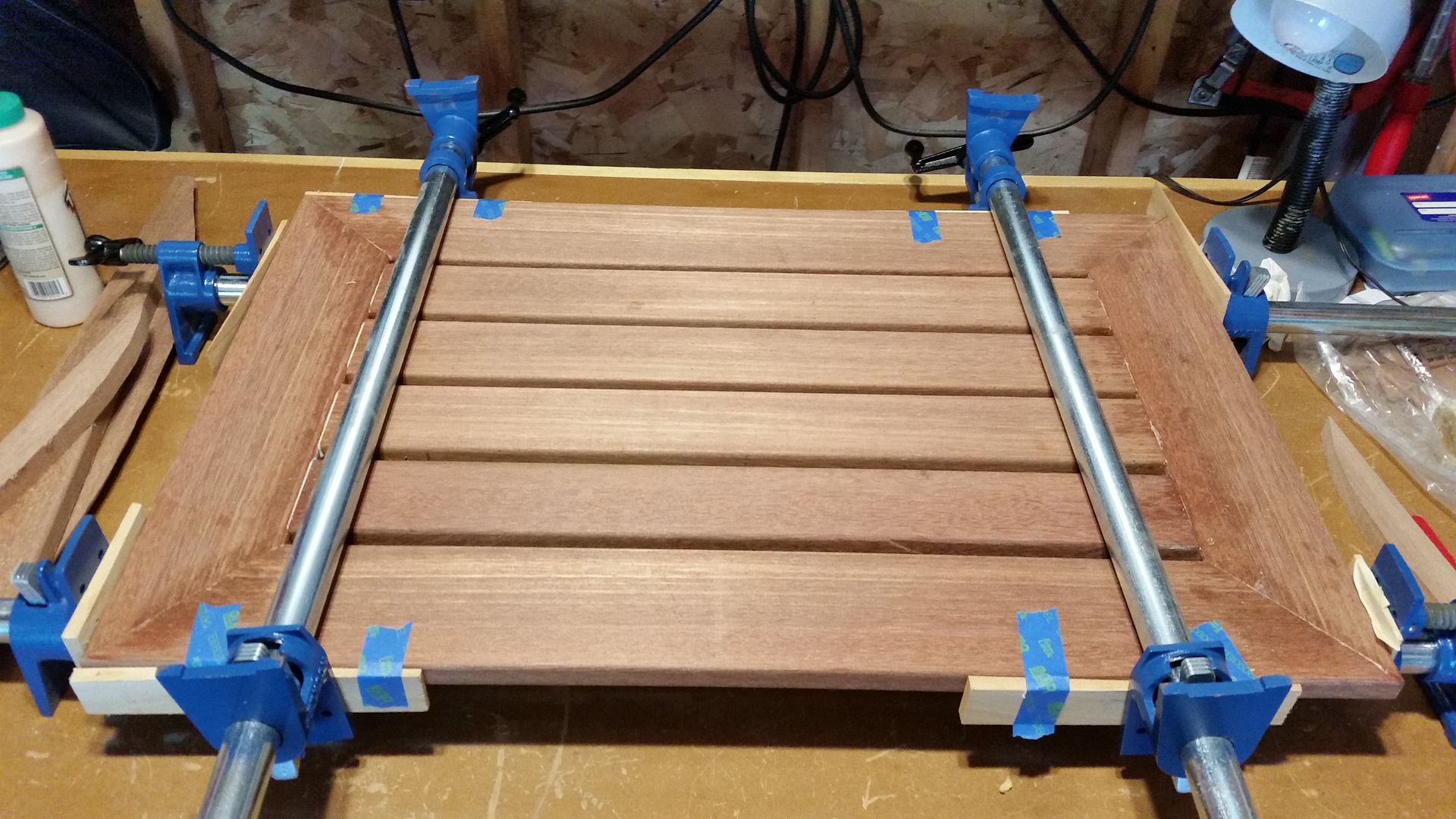

Clamps and painters tape to help position the slats -

Sanding parts with the RO90 -

The pile of Meranti -

This was a fun project and I'm pleased with the results. I've never owned a bandsaw or a spindle sander, some new tools to add to the collection. On to chair #2 (and chair #3, I've been asked to build another as a gift), and now I'm thinking about footrests and a matching table.

-Dom

The only modification I made was to the arm width. Norm's plans call for 5" wide arms, but why bother ripping a 5 1/2" board down a half inch? More room for beer bottles.

The wood is Meranti, recommended by the folks at The Woodery in Lunenburg MA. Of course, Adirondack chairs pal around in pairs so as Norm always does, this is the prototype -

It's finished in Watco Teak Oil. All hardware is Stainless Steel.

And some build pics, I didn't take many. The major Festool use was the RO90 with both the round pad and the delta pad, both with 320 Granat. I also used 60 with the delta pad to help take down the plugs. I also made use of the TS55 for the few straight cuts.

Unfinished -

Clamps and painters tape to help position the slats -

Sanding parts with the RO90 -

The pile of Meranti -

This was a fun project and I'm pleased with the results. I've never owned a bandsaw or a spindle sander, some new tools to add to the collection. On to chair #2 (and chair #3, I've been asked to build another as a gift), and now I'm thinking about footrests and a matching table.

-Dom