fshanno said:

Micke said:

So with a clear risk of offending someone - I hope your pulling our legs here overseas!

"... is fundamentally an American thing." - Sweet Jezus! if this is not intended as a joke you better get yourself a passport to cure that ignorance of yours.

That kind of statement is that what people around here (Sweden) would use to maliciously portrait Americans.

So take a chance and get to see the world.

Welcome Overseas!

( and no - we don't accept coloured beads as payment here in Europe... ;D )

Micke,

That did sound bad didn't it. Sorry. And yes, I was being cute and yes, I am ignorant.

It's just the frustration that FESTOOL doesn't seem to share the vision of replacing the table saw with the guided saw. Another guide maker here in the States calls it the "dead wood" concept and pursues the goal of replacing the table saw aggressively.

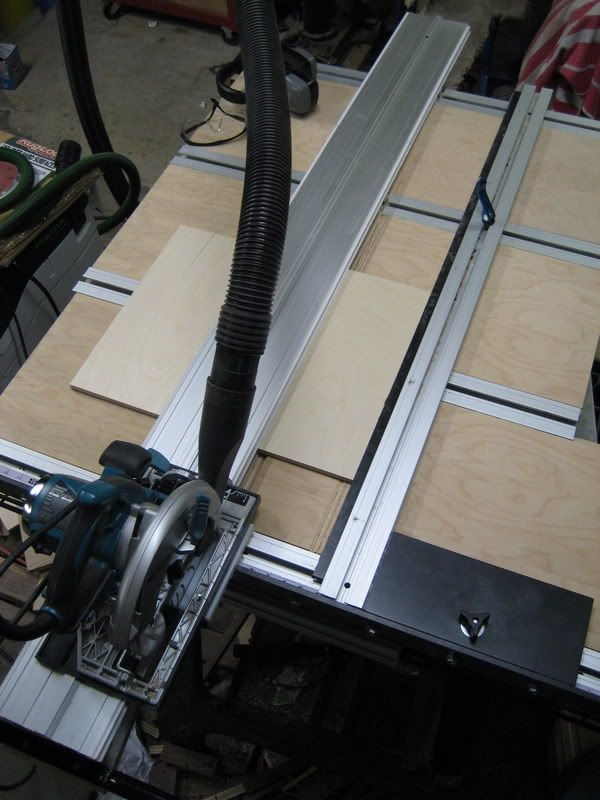

Look at the clever ripping jig in the photo. That's what set me off. Why are we having to do this? Four clamps and several pieces of wood. 8 or 9 parts. On a table saw? Just slide the fence over. I think FESTOOL can come up with a way to "just slide the fence over".

Your post raises an interesting question. I implied that only Americans would be pushing for FESTOOL to manufacture attachments extending the capability of the TS guide system so it could in effect replace the table saw and the panel saw for most cutting tasks. You are offended by this implication and that indicates the European FESTOOL owners community HAS been pushing for this capability. Do we all have a bigger vision for the potential of their product than they do?

You're forgiven

I may have sounded harsher than I intended - sorry :-(

Regarding the issue your addressing i would say that is actually two separate but related issues - Position and Clamping. Festool have a product line/system that address both I'd say. If we stick to what's applicable to the TS saw I get the following:

For the Positioning we have

a) Guide rail

b) The MFT (with some necessary 'jiggin')

c) Festool FS PA parallel guide - NEW!!!

d) FS-KS (the kind of useless angle device.; bought one but never really find any good use for it)

e) Stop flags

f) ...

For Clamping

a) The guide rail

b) The clamps - FSZ (screw), FS-HZ (quick)

c) Dedicated MFT clamping elements

d) The GECKOs

e) ..

What you're after (I guess) is something that would help you to quickly position your guide rail in relation to something. The "problem" with this approach is that whatever you do involves measuring & squaring - right? To answer you question "... Why are we having to do this?... "

If you analyse the jig of John it actually takes care of several different issues

Keeping the distance to the (repetitive) cuts

Squaring

"Levelling" (i.e. keeping the guide rail fully supported)

So any new "stand alone" accessory to the guide rail that can be launched with a potential for commercial success has to address all these three issues at once - otherwise were back at the "scrap piece" approach of John (which I happen to be quite nice once you've filled your scrap piece toolbox with the right items - that is, square pieces of e.g. birch plywood in reasonable sizes and thickness). I guess that the Festool engineers have a lot thinking invested here but since the brand opts for revolutions rather than incremental improvements I guess that we have to wait...

If it doesn't have to be stand alone I'd like the following MFT accessories:

MFT with rulers "everywhere"

A set of

a) combined guide rail & carpenters' try square to be attached to the MFT (which I guess is the item which you, fshanno, is looking for?)

b) an adjustable fence that rides in the slot of the MFT (square only to keep it "rigid")

Still the guide rail "Levelling" (which is the price for turning the table saw upside down) has to be addressed though...

So - in conclusion:

No hard feelings here overseas

I guess that Festools engineer do not lack ambition rather the problem is inherently hard

...

Btw - The "European Festool community" I'd say is pretty well represented here on the FOG