WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,198

This has been sitting too long, the time has come to use it or loose it.

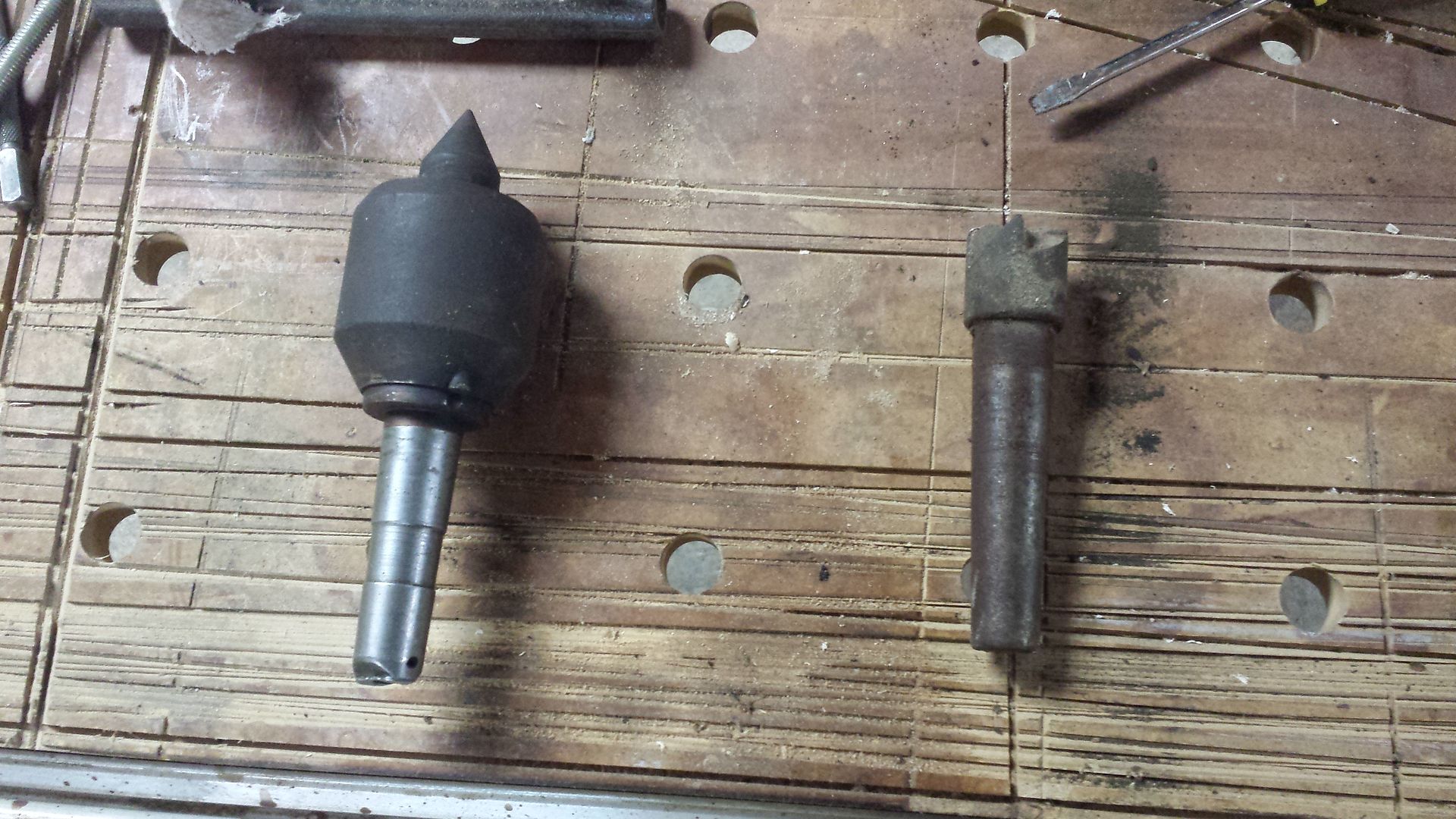

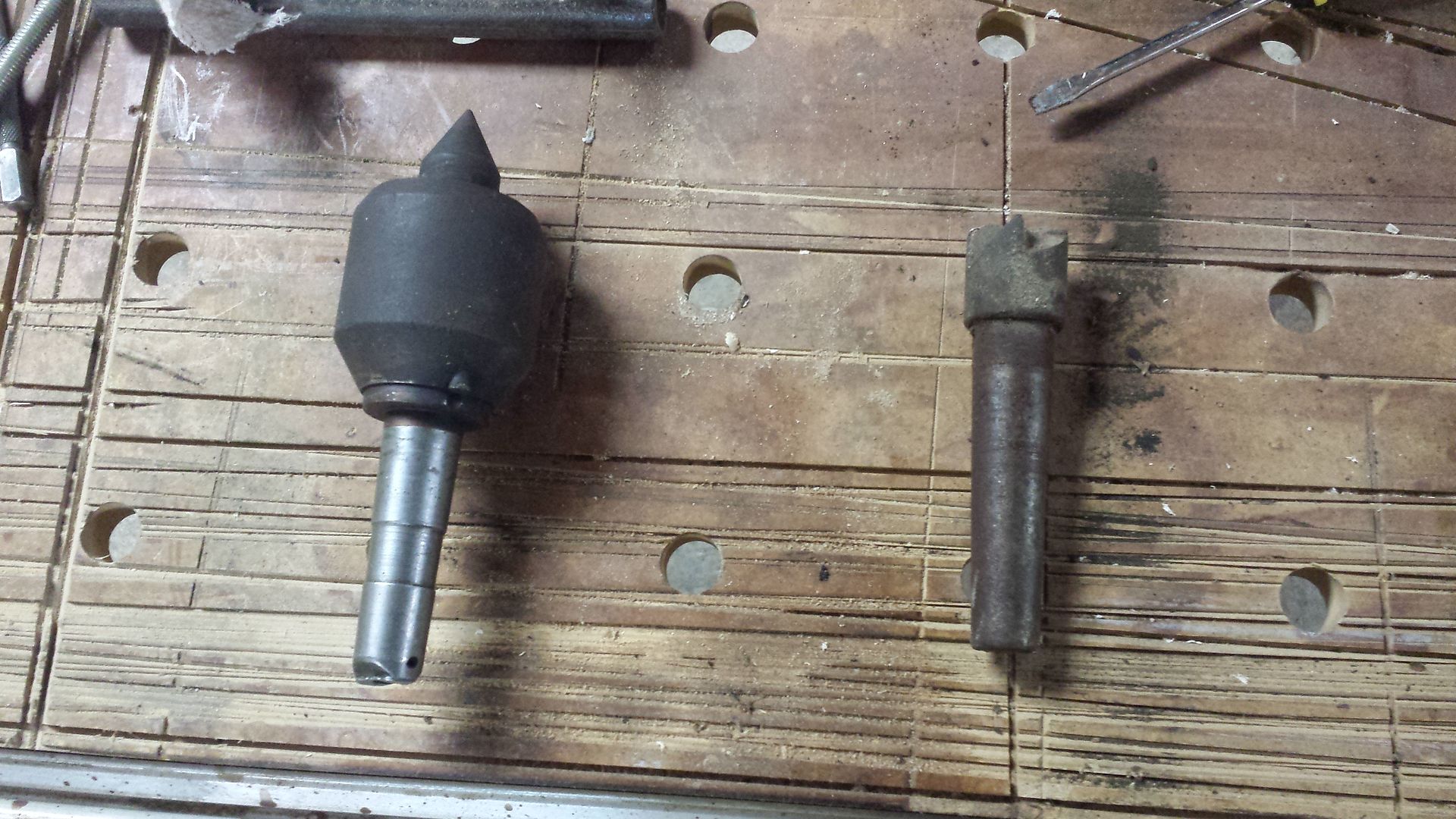

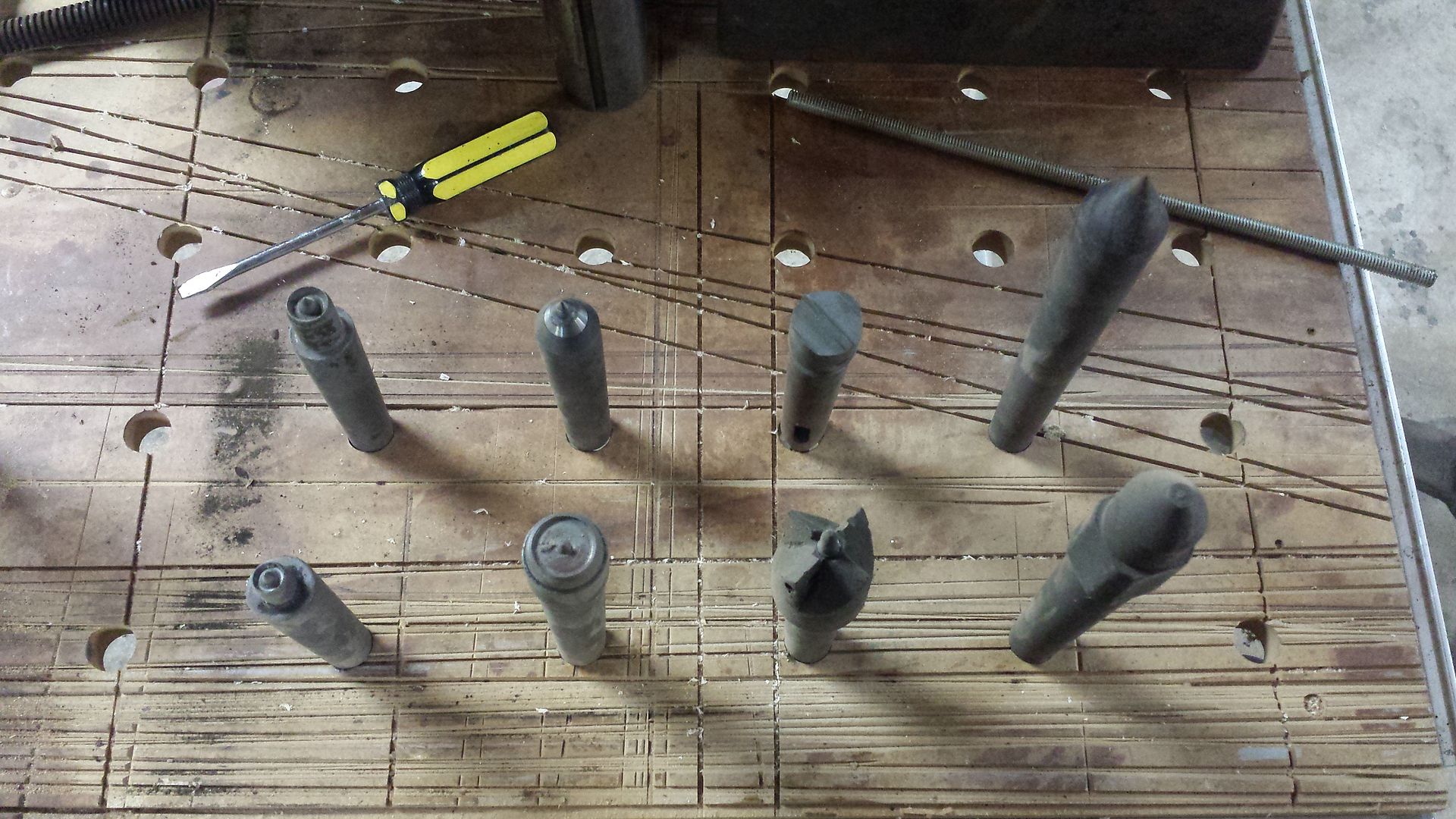

I have questions about these centers. I just got the center out of the tail stock (which seems to be a live center someone had made for it) and was able to remove the center from the head stock (seems to be a spur drive?)

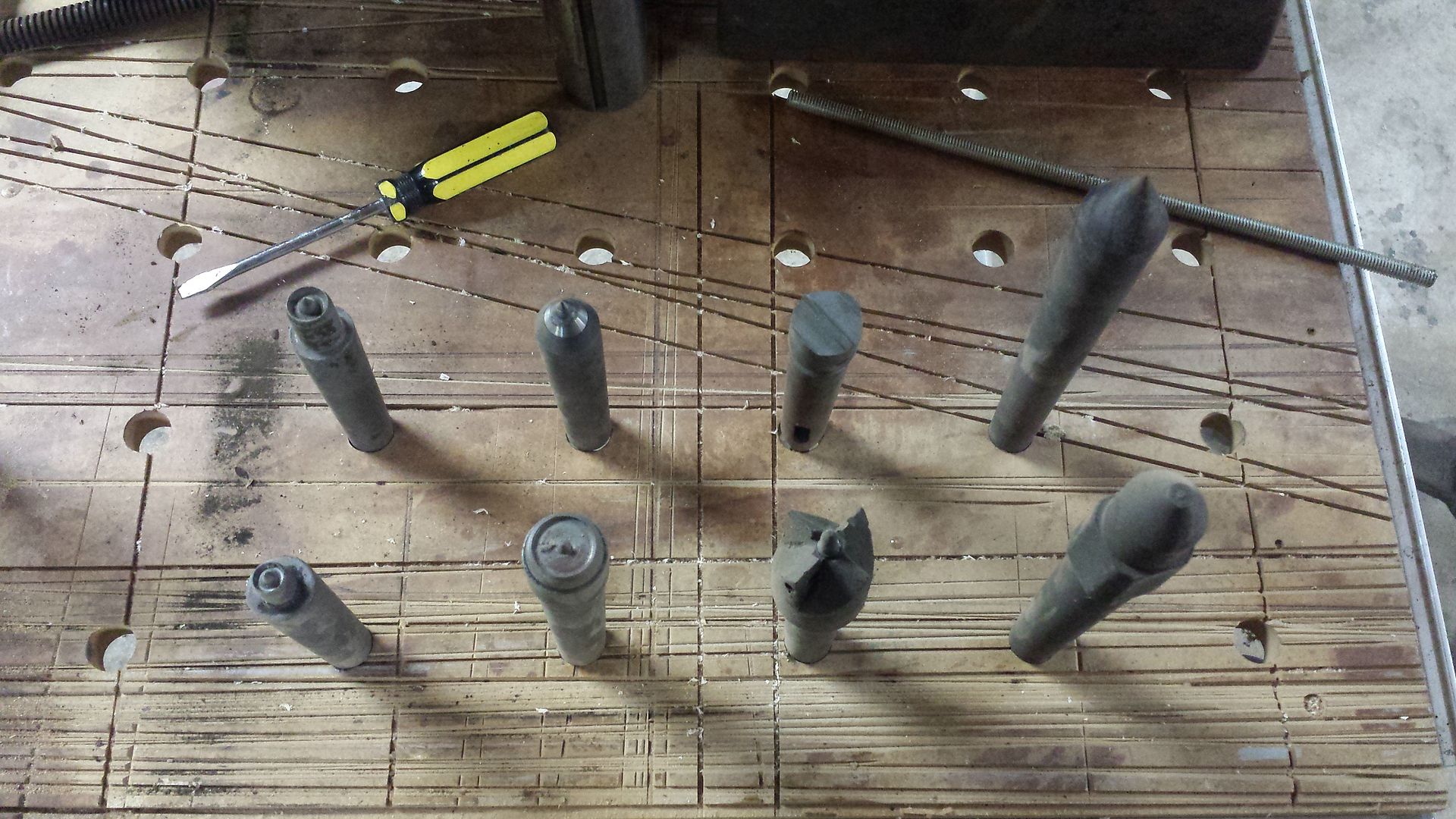

What are the additional centers for?

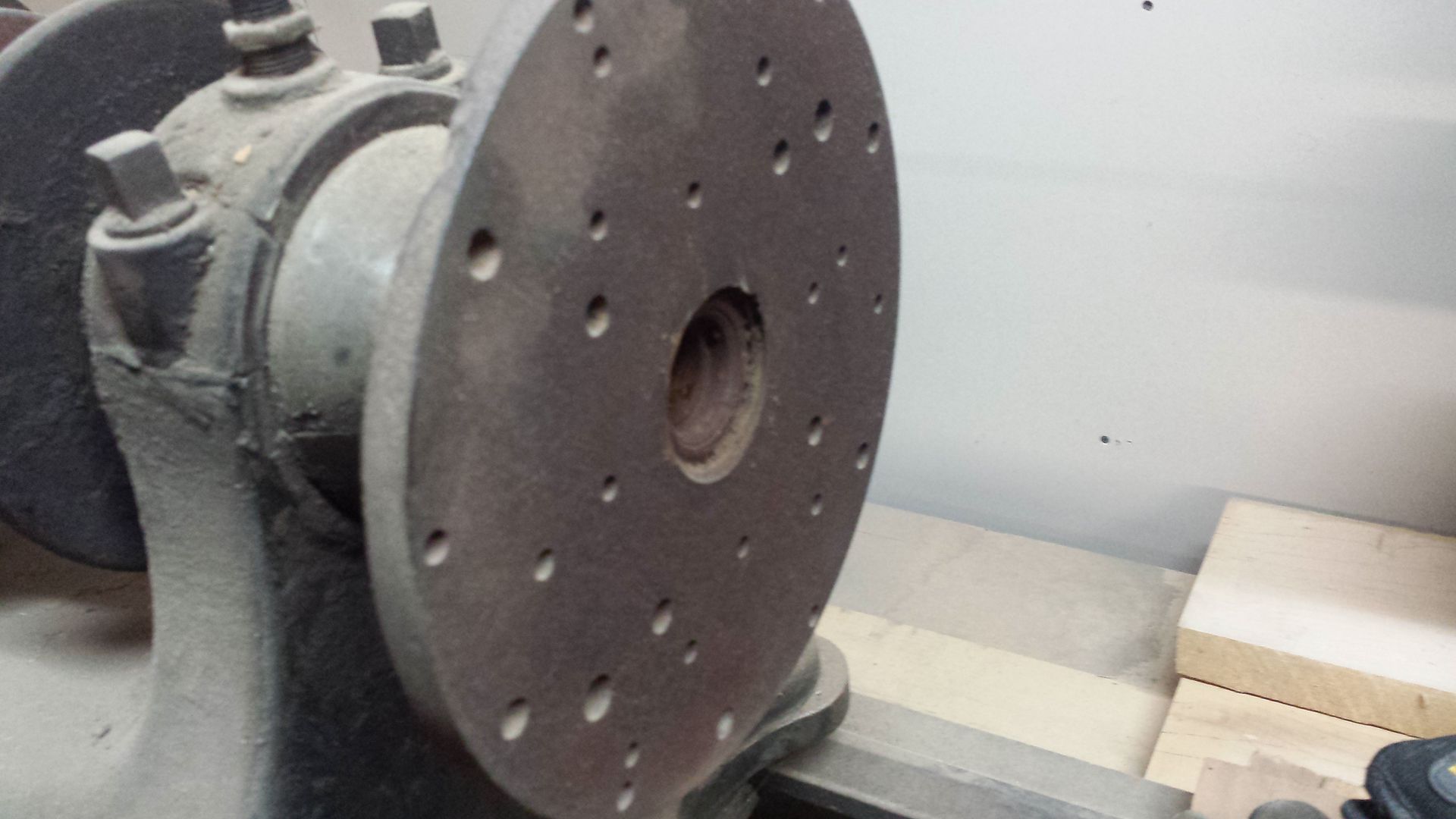

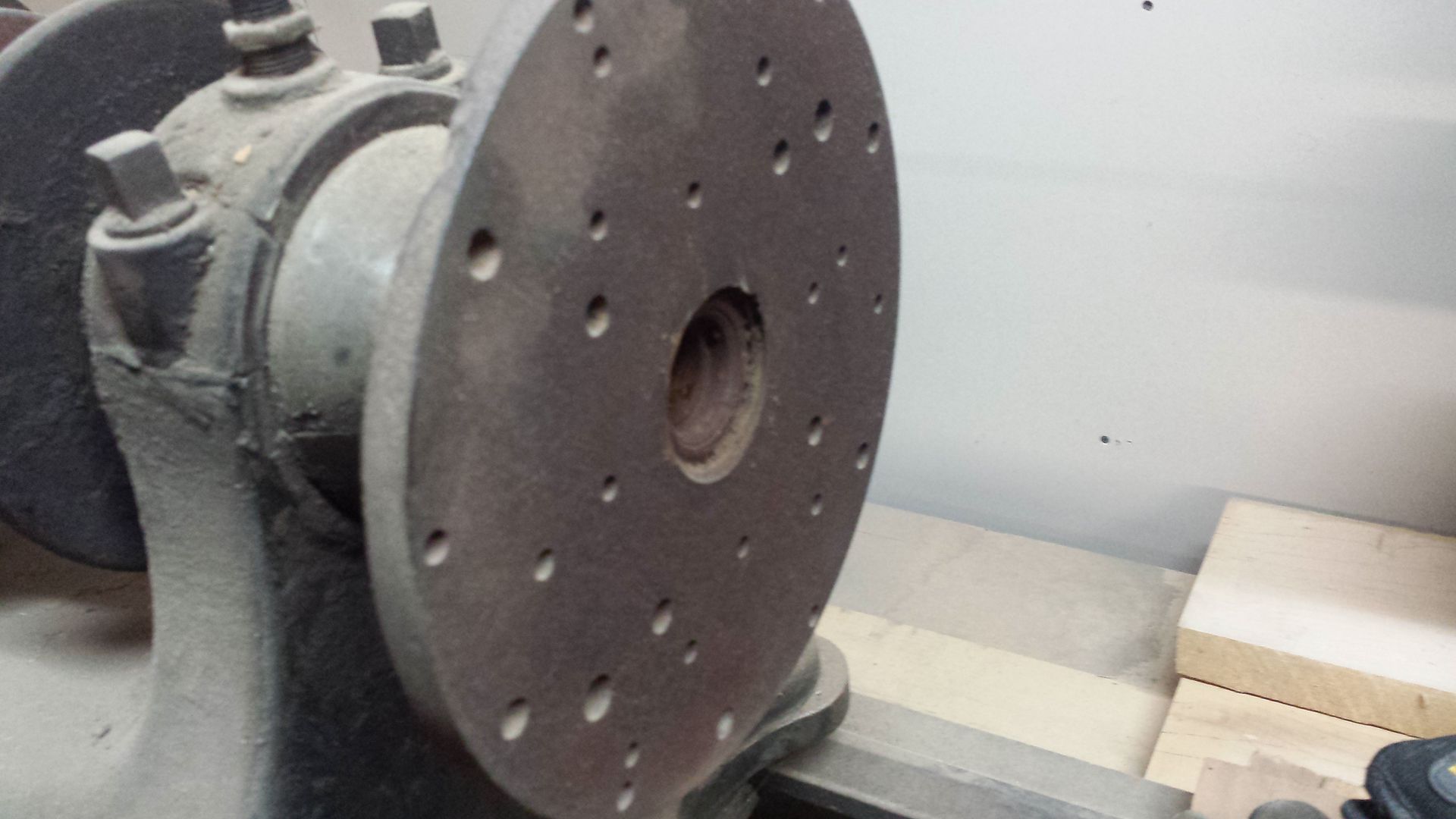

It also looks like the face plate will unthread as well?

Tailstock center on left headstock center on right

Another view:

Other centers that came with it, what are they, what/when are they used? (Yes, I have no clue at this moment)

Is it best to use a live center or dead center? Which ones are for which end? Those seem like dumb questions.

Current faceplate:

I have the tail stock disassembled and ready to finish cleaning and get painted. The legs will take some pretty extensive work to get back into the shape I want them to be.

I have questions about these centers. I just got the center out of the tail stock (which seems to be a live center someone had made for it) and was able to remove the center from the head stock (seems to be a spur drive?)

What are the additional centers for?

It also looks like the face plate will unthread as well?

Tailstock center on left headstock center on right

Another view:

Other centers that came with it, what are they, what/when are they used? (Yes, I have no clue at this moment)

Is it best to use a live center or dead center? Which ones are for which end? Those seem like dumb questions.

Current faceplate:

I have the tail stock disassembled and ready to finish cleaning and get painted. The legs will take some pretty extensive work to get back into the shape I want them to be.