Dead thread bump!

I've been looking at this product recently, as I'm wanting to upgrade my TS fence. Currently I have an OLD Incra TS fence (not the latest generation). My issue is that I now work in both metric and imperial systems (thanks Festool!) and would like to be able to switch back and forth on the table saw (I tend to model my projects in metric with Fusion 360 now. Yes, I realize I can make the back and forth switch in the CAD program.

I had thought about just setting up with both metric and imperial versions of the Incra, and then just swapping.

Then I saw the Harvey "big eye" system. They have the ability to swap out scales on the fence system. That would work, and I have suggested to them that they provide a dual scale (metric on top, imperial on the bottom) as that would negate having to swap the scales (good thing they both start at zero!!!!). I may just make that mod myself with some self stickie dual scale tape.

But, Harvey is promising a digital calibration readout that would allow me to keep the super accurate repeatability of the Incra fence. however, even though they show it at the woodworking shows, my inquiry to them this weekend has resulted in this:

"At this time, there is no official release date or additional information available. It’s simply a glimpse of what’s in development for the future. We’ll be sure to share updates on availability and pricing as soon as they become official."

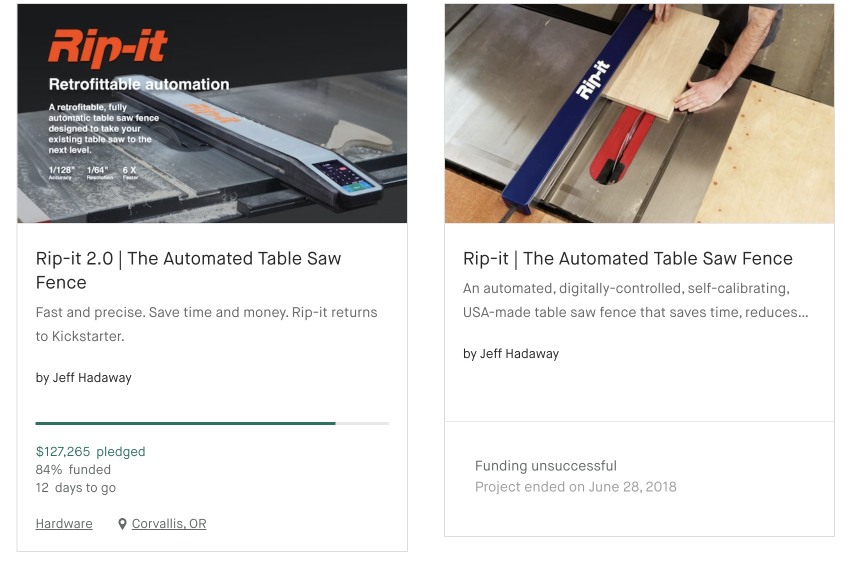

So then I found the Rip-it fence, looks awesome! Yes, concerns about about deflection, etc. But basically like having a 1 axis CNC positioner. And after digging around... dang, this thing first started 7 years ago (googled reddit thread), and they're always close to production, but still haven't delivered a thing (aside from a picture this month of reported packaged up rail parts). And blaming supply problems for "parts".

Starting to look like it will never be delivered (and the price keeps going up!).

[sad]

I think I did see a YouTube video where somebody made their own rack and pinion motorized fence. It might not be that hard (I already have an AvidCNC which is just 8020 based with a gear rack bolted on it. You could basically build one-third of that (no need for gantry or z-axis), just two motors for the single axis (slaved), setup Mach4 to disable two of the axis, and then use it to manually position for cuts (G-code manual entry).

Kinda wish I hadn't had that thought.......