WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,198

I am not sure what has been going on behind the closed doors in my shop, but I think my old bs was up to no good.

First I won a 1952 Crescent 32" bandsaw from an industrial auction site.

It was a really ugly John Deere green paint job. [blink]

I think I had the saw unloaded, in the shop and down to the frame in about 45 minutes.

The saw was gone through, sanded (festool sanders and vacs are perfect for this work), primed, painted, reassembled, wired, wheels balanced, and cutting some

10"x10" old barn beams in under a week.

Saw has a 32" throat, 13" under the guides, 16' 4" blade and a 3hp 3ph motor.

Well, a week went by, all was well with the Crescent until I stumbled on a poorly advertised auction.

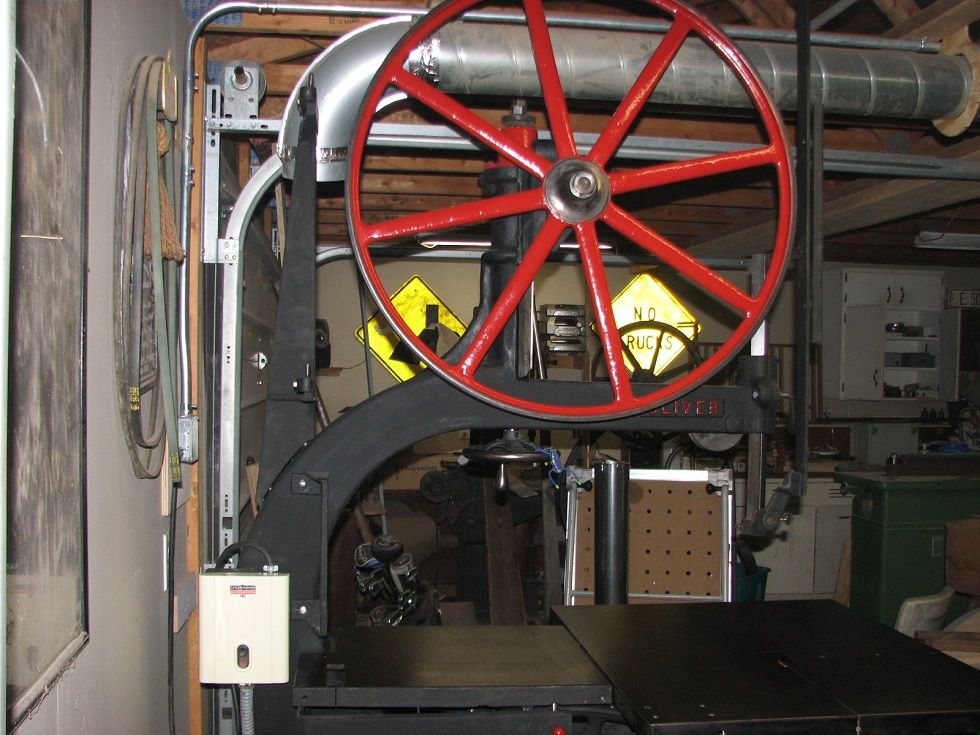

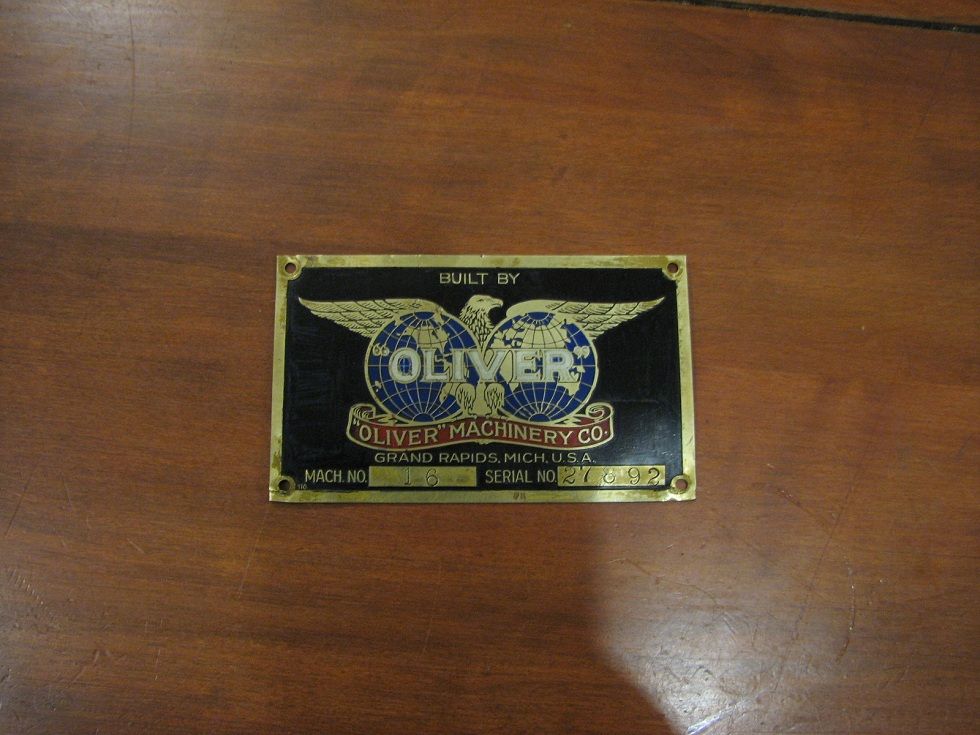

Next thing I know an Oliver model 16, 36" bandsaw jumped on my trailer and strapped itself down. A State S-3 OSS did the same thing too.....

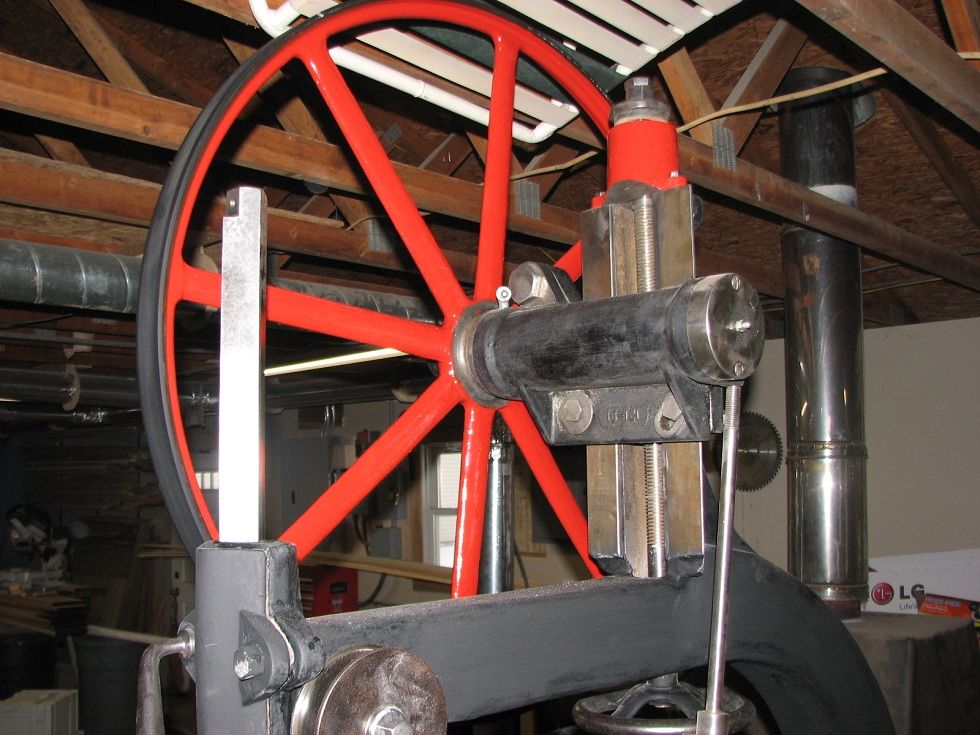

The Oliver was built in 1922 and is one of their first (an industry first) direct drive machine.

It has a 36" throat, 16" under the guides, 17' to 19' blade and a 3hp 3ph motor.

First I won a 1952 Crescent 32" bandsaw from an industrial auction site.

It was a really ugly John Deere green paint job. [blink]

I think I had the saw unloaded, in the shop and down to the frame in about 45 minutes.

The saw was gone through, sanded (festool sanders and vacs are perfect for this work), primed, painted, reassembled, wired, wheels balanced, and cutting some

10"x10" old barn beams in under a week.

Saw has a 32" throat, 13" under the guides, 16' 4" blade and a 3hp 3ph motor.

Well, a week went by, all was well with the Crescent until I stumbled on a poorly advertised auction.

Next thing I know an Oliver model 16, 36" bandsaw jumped on my trailer and strapped itself down. A State S-3 OSS did the same thing too.....

The Oliver was built in 1922 and is one of their first (an industry first) direct drive machine.

It has a 36" throat, 16" under the guides, 17' to 19' blade and a 3hp 3ph motor.