Rob-GB

Member

- Joined

- Nov 7, 2009

- Messages

- 1,101

Those that know me know that I am prone to finding solutions in odd ways or adapting age old ideas that I have read about.

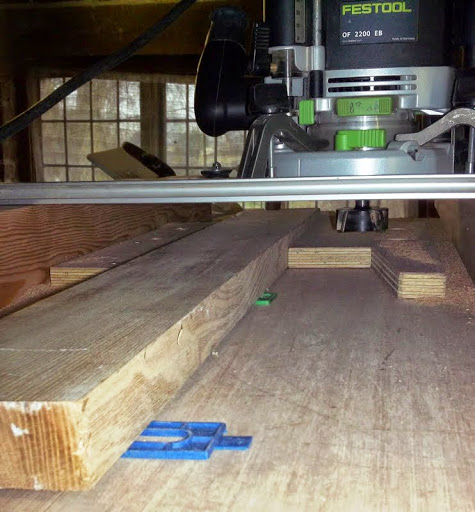

Today, however, I turned my router table upside down [eek] ;D

I have a limited amount of Elm in odd lengths and sizes to make the rest of the vanity cabinet, some is pretty warped. So I needed to get a face on each board flat, on site with just my Festools and some offcuts of ply and B.C. pine from other projects in the house....the obvious solution was to make a sled.............

I looked about for a sturdy carriage and found it already attached to my OF2200

I re-used the holding system that I made the other week for some hand planing tasks on the MFT

Used 50mm dia tenoning cutter

and some small plastic wedges to stop any wobble.

I slowed the router speed down (2) and set the cutter to the lowest point I could see on the board, on the worst one I had a 4mm deep cut in the middle of the board but I had no kick back at all and - one of the best likes I have about this router, it was not screaming from being used. Using big diameter cutters freehand in a router is usually frowned upon but this combination was a breeze to work with...after all, it was still mounted in a table ;D ;D

The dust extraction was only partial, which is always the issue with a cutter that far slung below the sled, but having it running did help and made quick work of dust clearance before the next board was installed thus maintaining the ply base datum.

Tomorrow I plan to face up the opposite face and thickness them so I can start making the curved/faceted vanity front and door the same way.

Rob.

Today, however, I turned my router table upside down [eek] ;D

I have a limited amount of Elm in odd lengths and sizes to make the rest of the vanity cabinet, some is pretty warped. So I needed to get a face on each board flat, on site with just my Festools and some offcuts of ply and B.C. pine from other projects in the house....the obvious solution was to make a sled.............

I looked about for a sturdy carriage and found it already attached to my OF2200

I re-used the holding system that I made the other week for some hand planing tasks on the MFT

Used 50mm dia tenoning cutter

and some small plastic wedges to stop any wobble.

I slowed the router speed down (2) and set the cutter to the lowest point I could see on the board, on the worst one I had a 4mm deep cut in the middle of the board but I had no kick back at all and - one of the best likes I have about this router, it was not screaming from being used. Using big diameter cutters freehand in a router is usually frowned upon but this combination was a breeze to work with...after all, it was still mounted in a table ;D ;D

The dust extraction was only partial, which is always the issue with a cutter that far slung below the sled, but having it running did help and made quick work of dust clearance before the next board was installed thus maintaining the ply base datum.

Tomorrow I plan to face up the opposite face and thickness them so I can start making the curved/faceted vanity front and door the same way.

Rob.