dirtydeeds

Member

- Joined

- Nov 22, 2007

- Messages

- 1,009

thank you to all of you who made suggestions for fixing my OF1400, particular thanks go to Mike Chrest

mike subsequently pm'd me and suggested i posted photos. i couldnt resist the chance to show off :

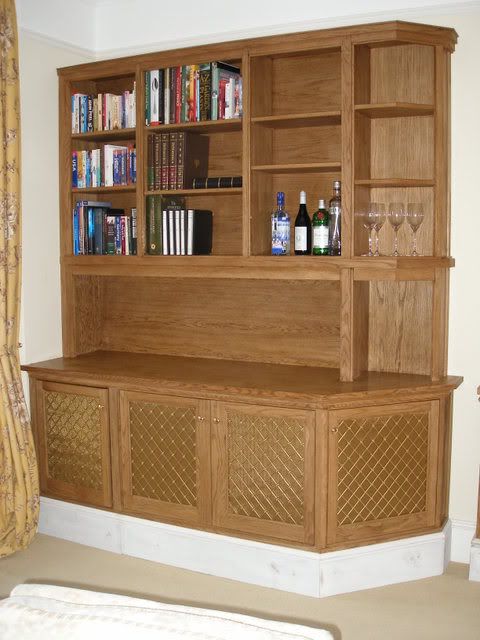

the project is in an edwardian house (1906) in dulwich village uk.

bedroom wardrobes in mdf. the rest in oak:- 3 radiator cabinets, a hi fi unit and a main cabinet with lighting and some torsion box shelving

wardrobes before painting

hi fi cabinet

main cabinet

radiator cabinets, one of which ive shown already

torsion box shelving mostly hidden by sofa unfortunatly

mike subsequently pm'd me and suggested i posted photos. i couldnt resist the chance to show off :

the project is in an edwardian house (1906) in dulwich village uk.

bedroom wardrobes in mdf. the rest in oak:- 3 radiator cabinets, a hi fi unit and a main cabinet with lighting and some torsion box shelving

wardrobes before painting

hi fi cabinet

main cabinet

radiator cabinets, one of which ive shown already

torsion box shelving mostly hidden by sofa unfortunatly