Cheese said:

Holmz said:

The engineered concretes have a lot of glass in them.

Usually the underside is formed with webs or gussets when that material is used.

It is more expensive but lighter for the same strength.

[member=40772]Holmz[/member]

This doesn't appear to be engineered concrete, correct?

Are you familiar with the engineered concrete expense ratio and weight ratio compared to regular concrete?

I don't appear like engineered concrete to me.

Even the guys that do this all the time seem to have mostly moved to the engineered concrete.

Somewhat for strength, consistency, and ease of use.

And probably just as much or more for not bust a gut installing it.

Usually the labor is more that the materials, and they are passing the material costs on.

The main reason to not use the engineered products is if they will not sell it to someone untrained and to keep their products within a known chain of custody and control.

The Mrs wanted to take a course a few years ago, and so we did.

I have not done any real projects, but I have a bathroom counter coming up.

We did shift track and did a couple of floors, which are also engineered products but 90% different in approach. The only thing the same was mixing and sanding really.

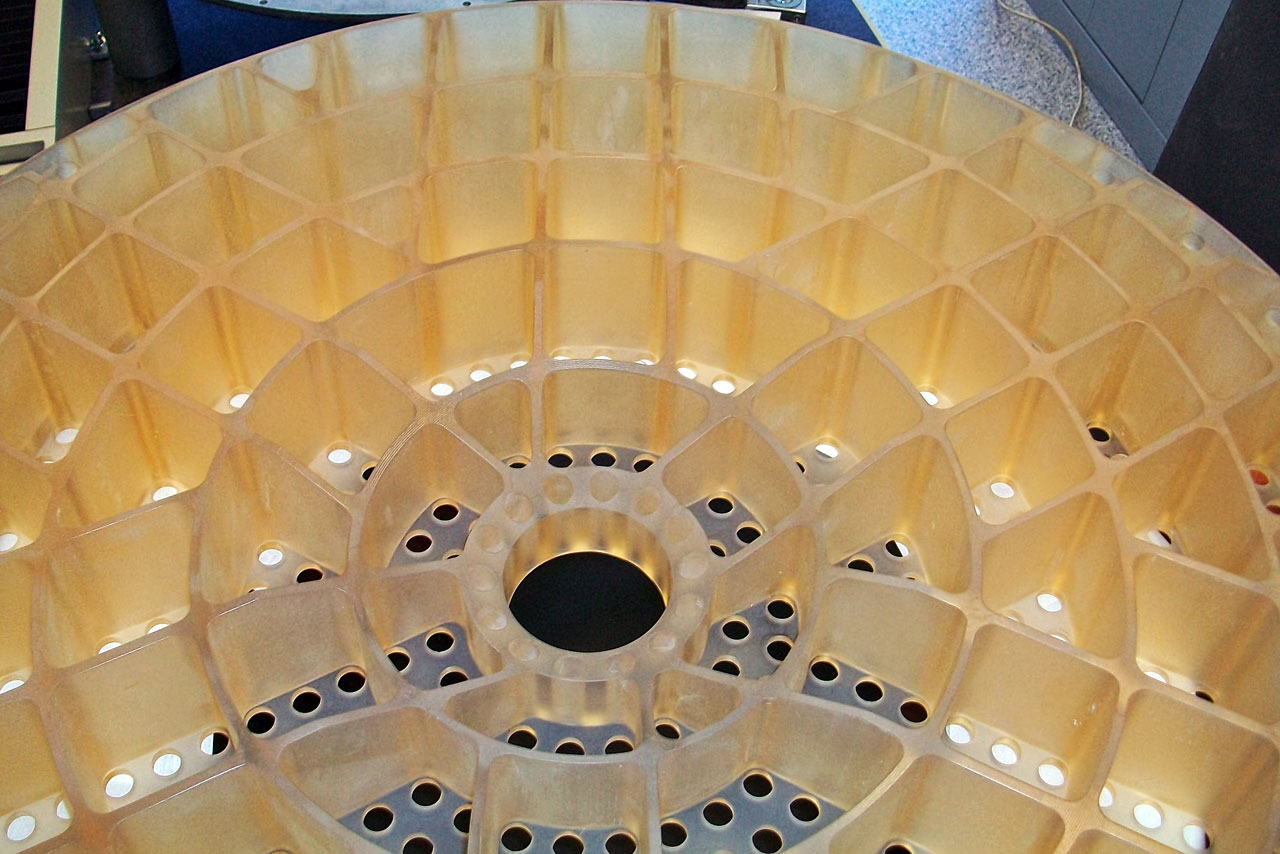

As for weight, they can look like the massive telescope mirrors where the back-side resembles a belgian waffle. Therefore one can have higher webs (for stiffness/strength), and the webs have a lot higher glass to concrete ratio, with a ~1/4" layer of less strong (but still 3x stringer than concrete) engineered product.

They also have glass rebar which has exactly the same coefficient of expansion as the glass in the concrete. Those are in the 3-mm and upwards sizes. Not sure if they are using those types of products in bridges and other civil projects, but they are generally headed that way to my knowledge. Most thing 'concrete' break in tension, which is where the engineered products excel. Concrete is plenty strong in compression, but earthquakes produce the tensile forces.

The engineered counters do not fly away on their own like a Findhorn roof design. They are still heavy enough.

But it is a nice looking counter he did. I would just not want to have to move it much.

There is nothing to find fault with, it just he went old-school on it... and he should be proud of it.