I have been lurking on the forum for some time now and lots of great posts on DIY MFTs.

I plan to make a diy MFT using the toughbuilt C700 as the legs, and building a temporary frame using 2x4s. i will use this as the base of an MFT.

The MFT i would like to make will be around 2000mm (6.5') by 800mm (2.5'). I think, I would like to build the separate "lift-off" MFT top with an aluminium frame, but in the future use the rail hinge system. i had a couple of questions that i seem to been getting more confused about and wandering if anyone could help?

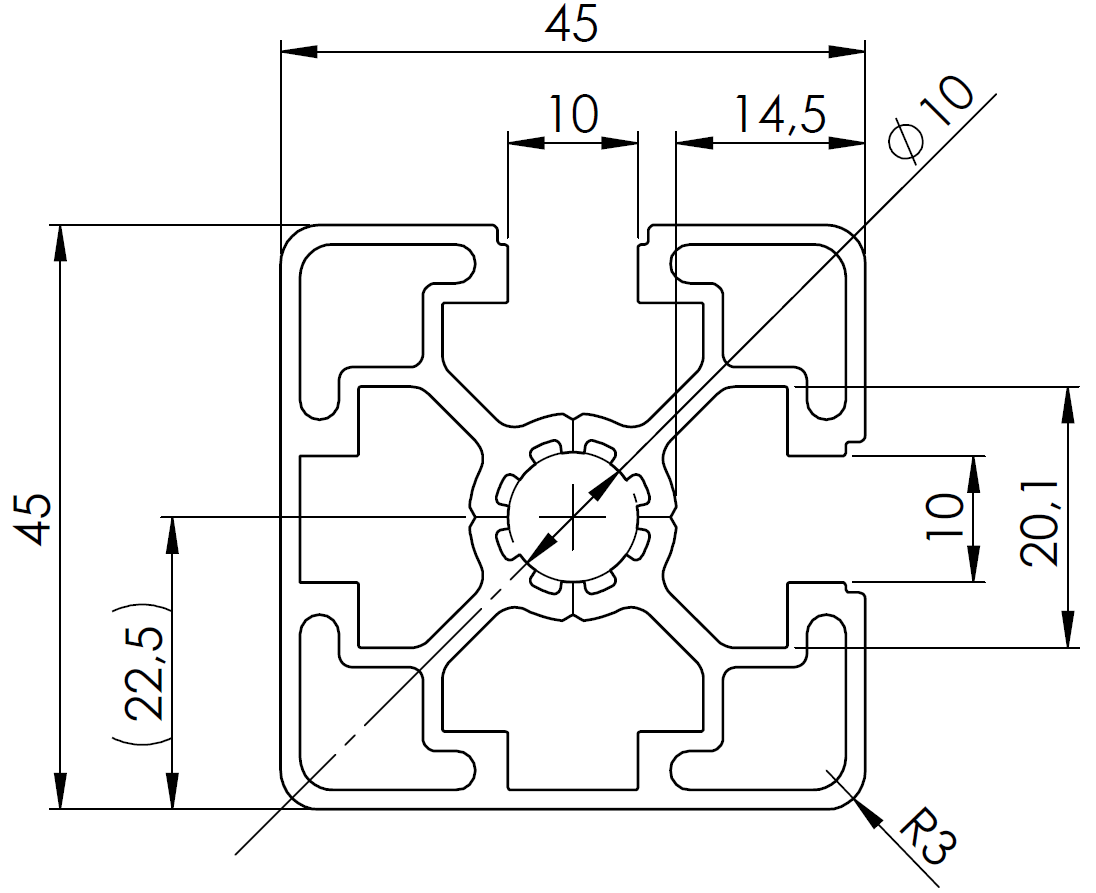

1) is there any aluminum extrusion that would support installing the rail hinge system? (i looked at the festool 496824 but this is too expensive for 2m). I have seen examples of sides being made with a combination of wood and aluminium but would rather just use aluminium as a frame / sides

2) has anyone seen any examples of lift of MFTs using an aluminium frame that didnt need too much modifying to the aluminium?

3) should i just not bother with the aluminium, keep it simple and use the 2x4 frame as the support instead?

I plan to make a diy MFT using the toughbuilt C700 as the legs, and building a temporary frame using 2x4s. i will use this as the base of an MFT.

The MFT i would like to make will be around 2000mm (6.5') by 800mm (2.5'). I think, I would like to build the separate "lift-off" MFT top with an aluminium frame, but in the future use the rail hinge system. i had a couple of questions that i seem to been getting more confused about and wandering if anyone could help?

1) is there any aluminum extrusion that would support installing the rail hinge system? (i looked at the festool 496824 but this is too expensive for 2m). I have seen examples of sides being made with a combination of wood and aluminium but would rather just use aluminium as a frame / sides

2) has anyone seen any examples of lift of MFTs using an aluminium frame that didnt need too much modifying to the aluminium?

3) should i just not bother with the aluminium, keep it simple and use the 2x4 frame as the support instead?