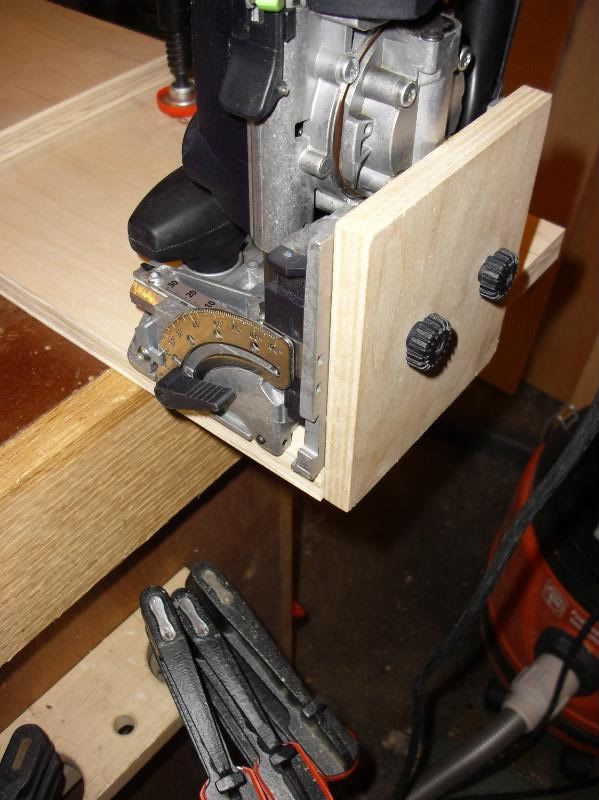

The angle bracket too shaky for me so I'd been thinking about building a more robust version from aluminum angle but came up with this idea made from scrap 1/2" ply:

The bottom plate of the domino is the same distance from the bit as the fence is at it's lowest position so I made a stop fixing it in place with the screws from the angle bracket. It indexes the vertical mortise 10mm on center from the outside edge of the horizontal piece. I remove it and flip the fence to the horizontal position referencing the outside face of the perpendicular member to complete the corner.

The bottom plate of the domino is the same distance from the bit as the fence is at it's lowest position so I made a stop fixing it in place with the screws from the angle bracket. It indexes the vertical mortise 10mm on center from the outside edge of the horizontal piece. I remove it and flip the fence to the horizontal position referencing the outside face of the perpendicular member to complete the corner.