sofa_king_rad

Member

- Joined

- Mar 26, 2016

- Messages

- 100

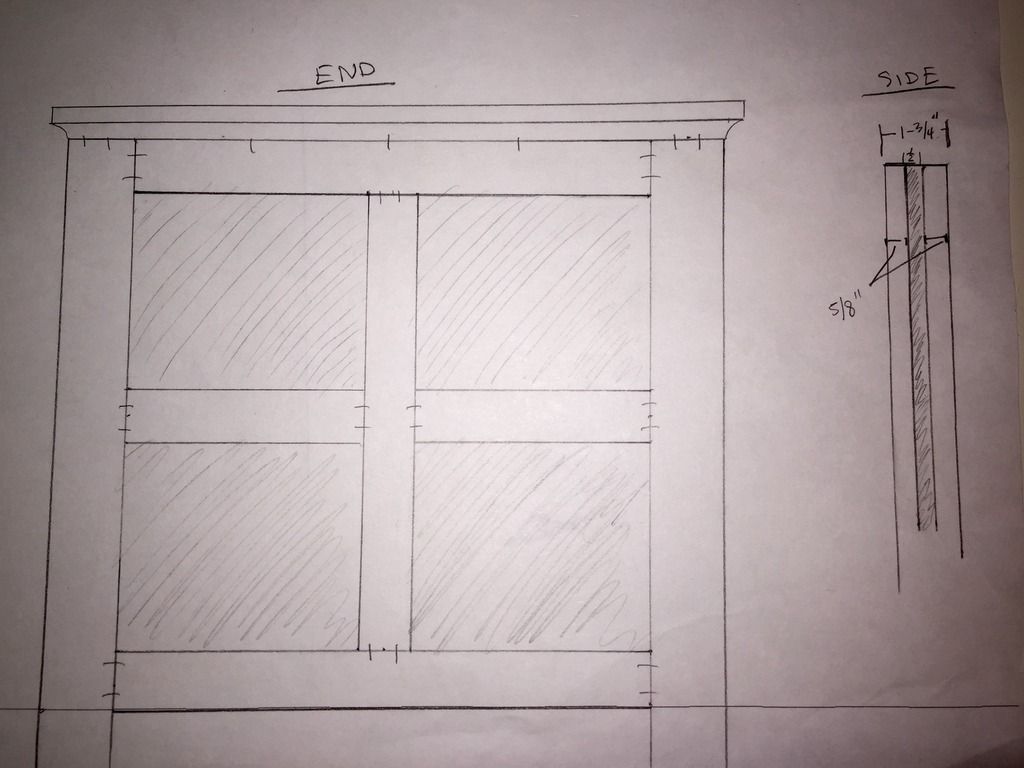

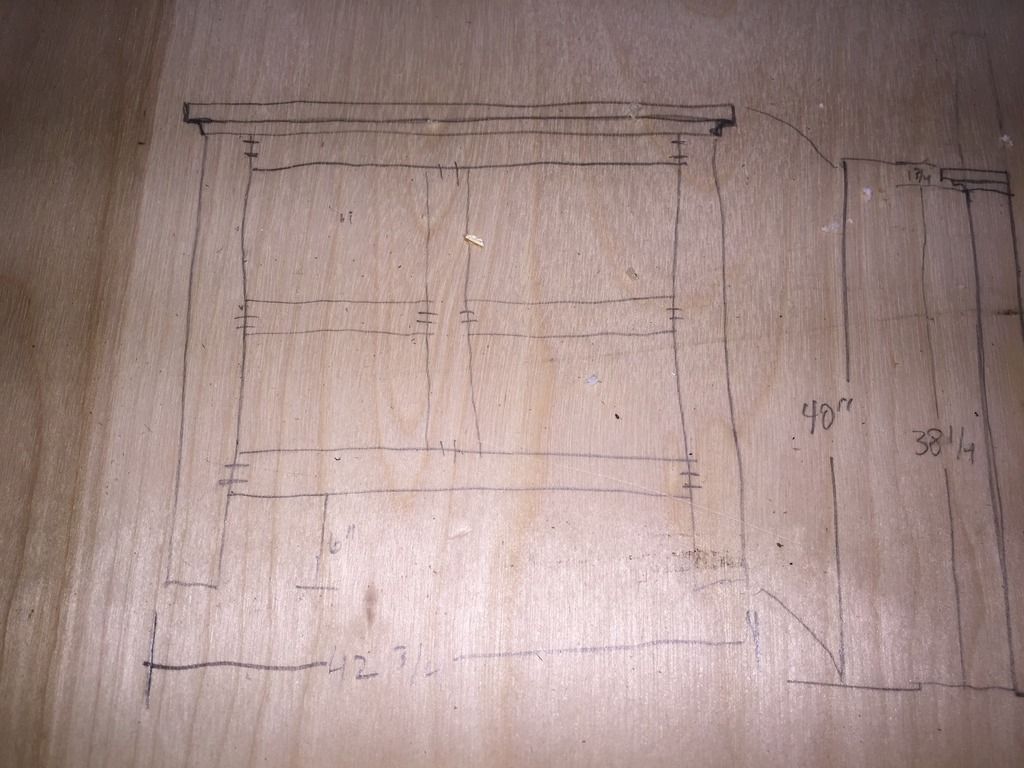

i bought some surfaced 4/4 curly birch boards. I've ripped them down to boards roughly 4.5" wide by 40 inches long. The boards weren't wide enough to do three 3.5" wide boards...so I went with 4.5" with a goal to make 4 bed posts at 4" wide by roughly 1.75" thick.

SO, i need to laminate boards together. I'm looking for any tips, techniques or tricks.

How far apart do you space clamps?

How many boards can I clamp within one set of clamps....is it okay clamping all four pairs together within the same set of clamps?

SO, i need to laminate boards together. I'm looking for any tips, techniques or tricks.

How far apart do you space clamps?

How many boards can I clamp within one set of clamps....is it okay clamping all four pairs together within the same set of clamps?