WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,198

Well, I decided it was time to get serious and step up to the big boy machines. [wink]

I have been looking for a single end tenoner for quite some time. They were always too far from home or not what I was looking for.

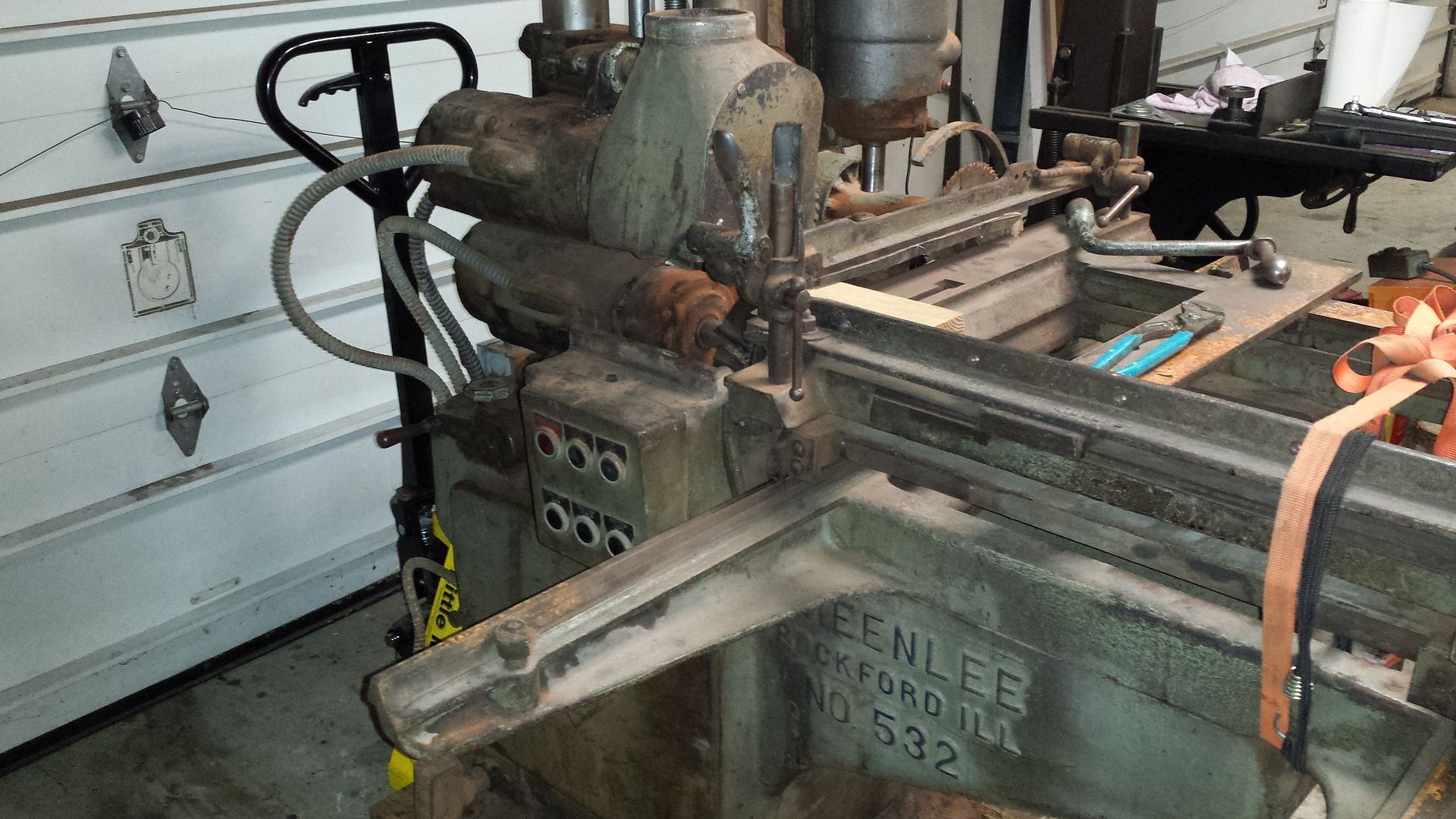

This machine required a 500 mile round trip to the auction and a 22 hour day.

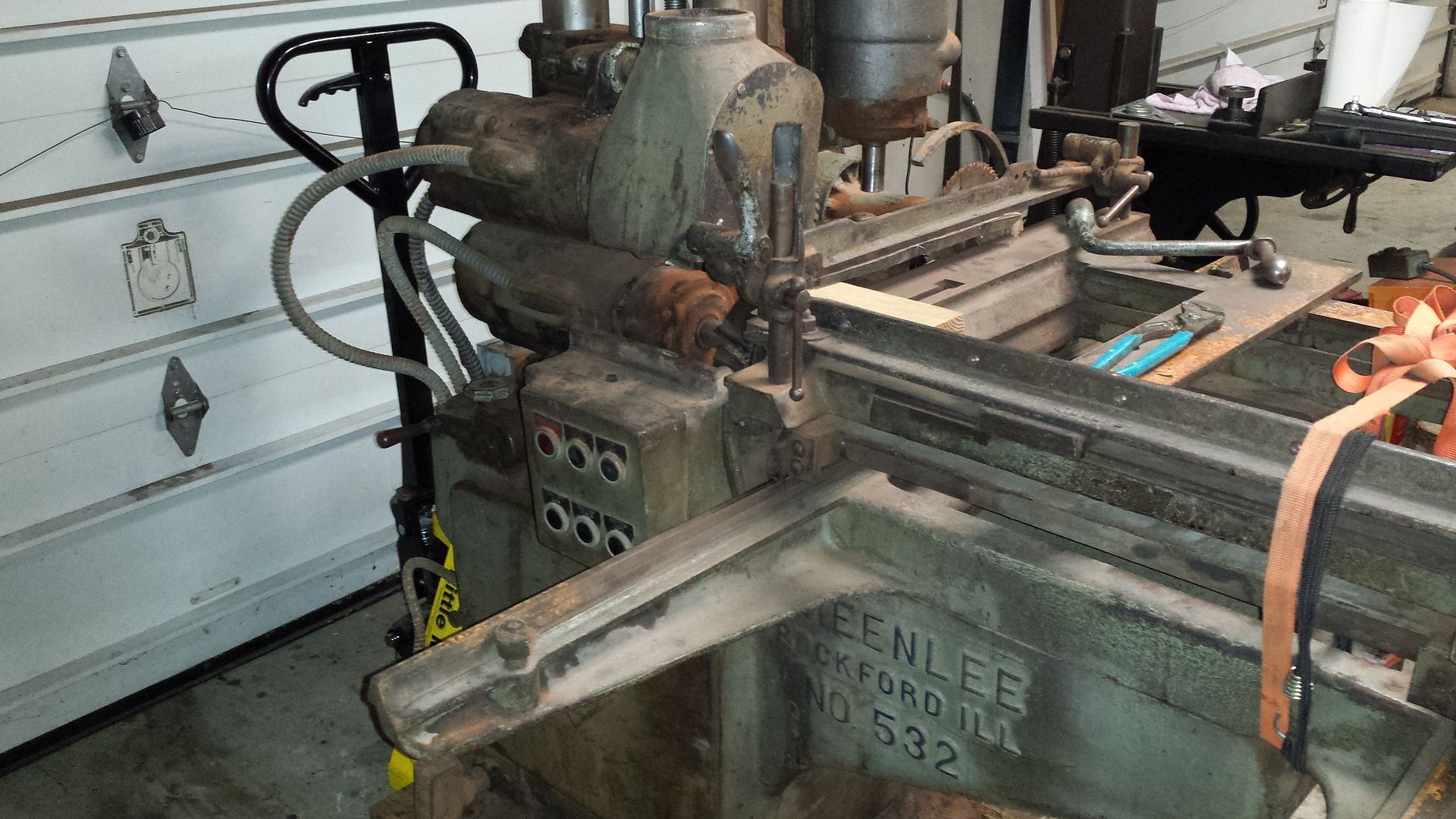

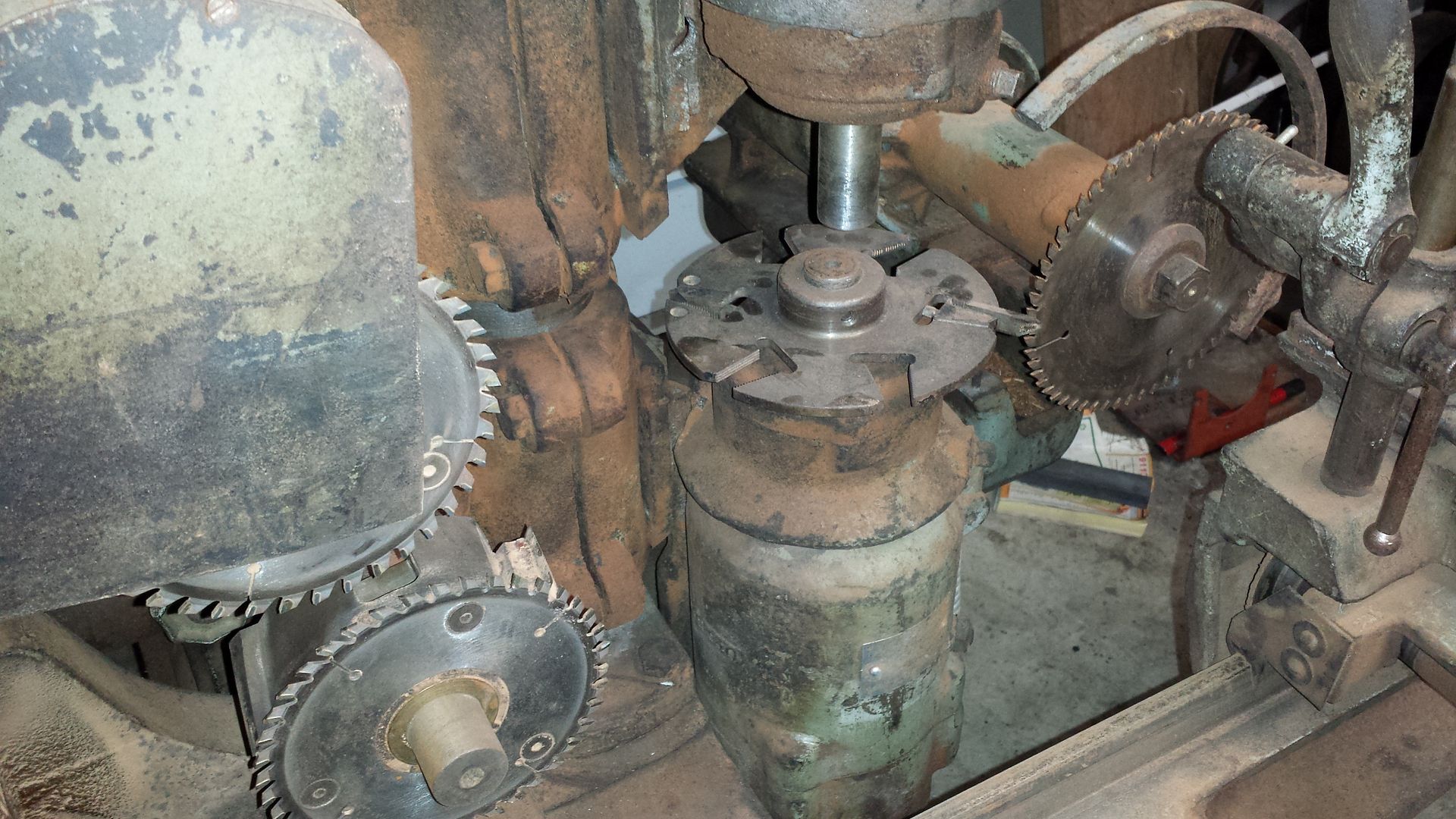

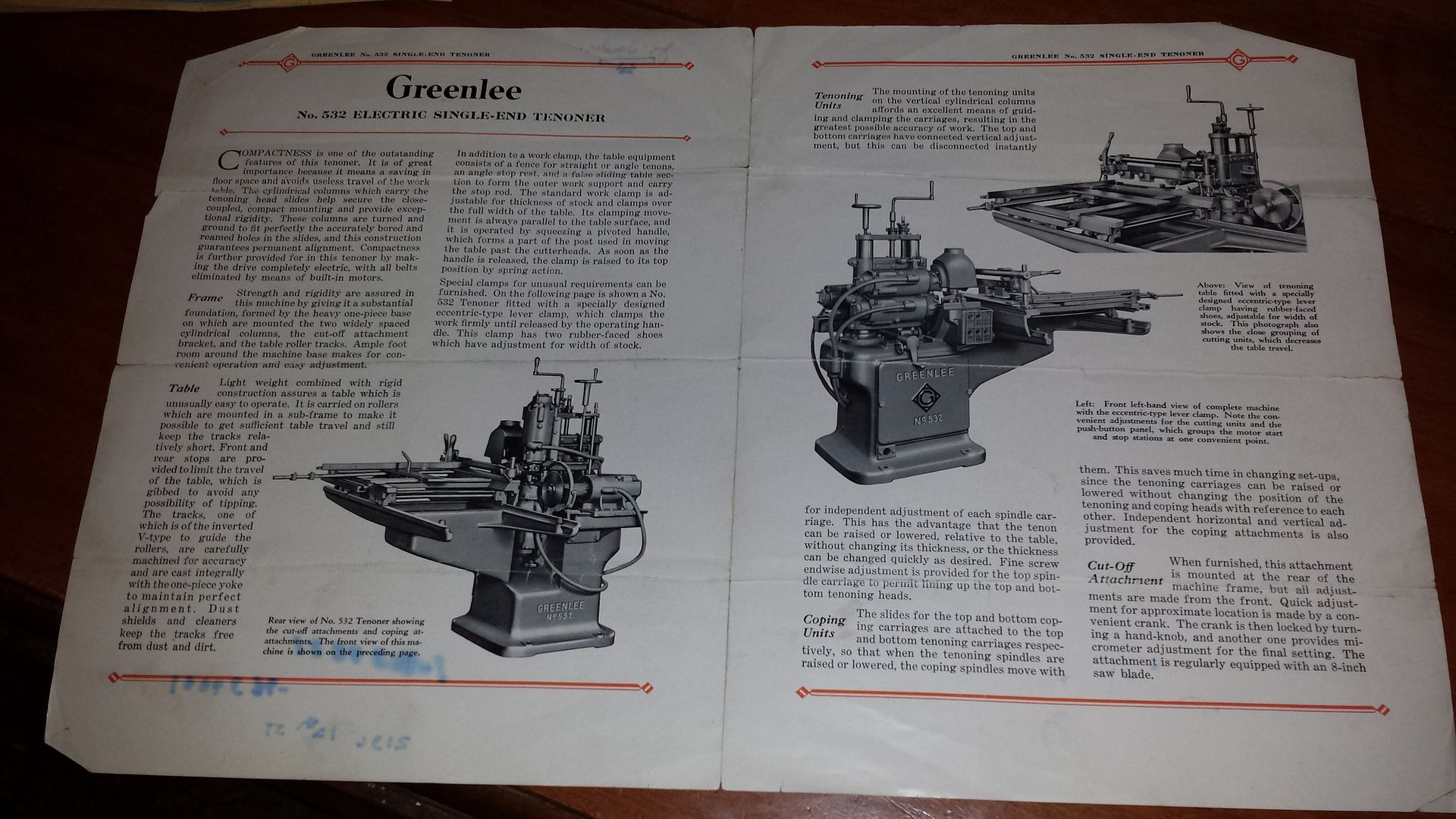

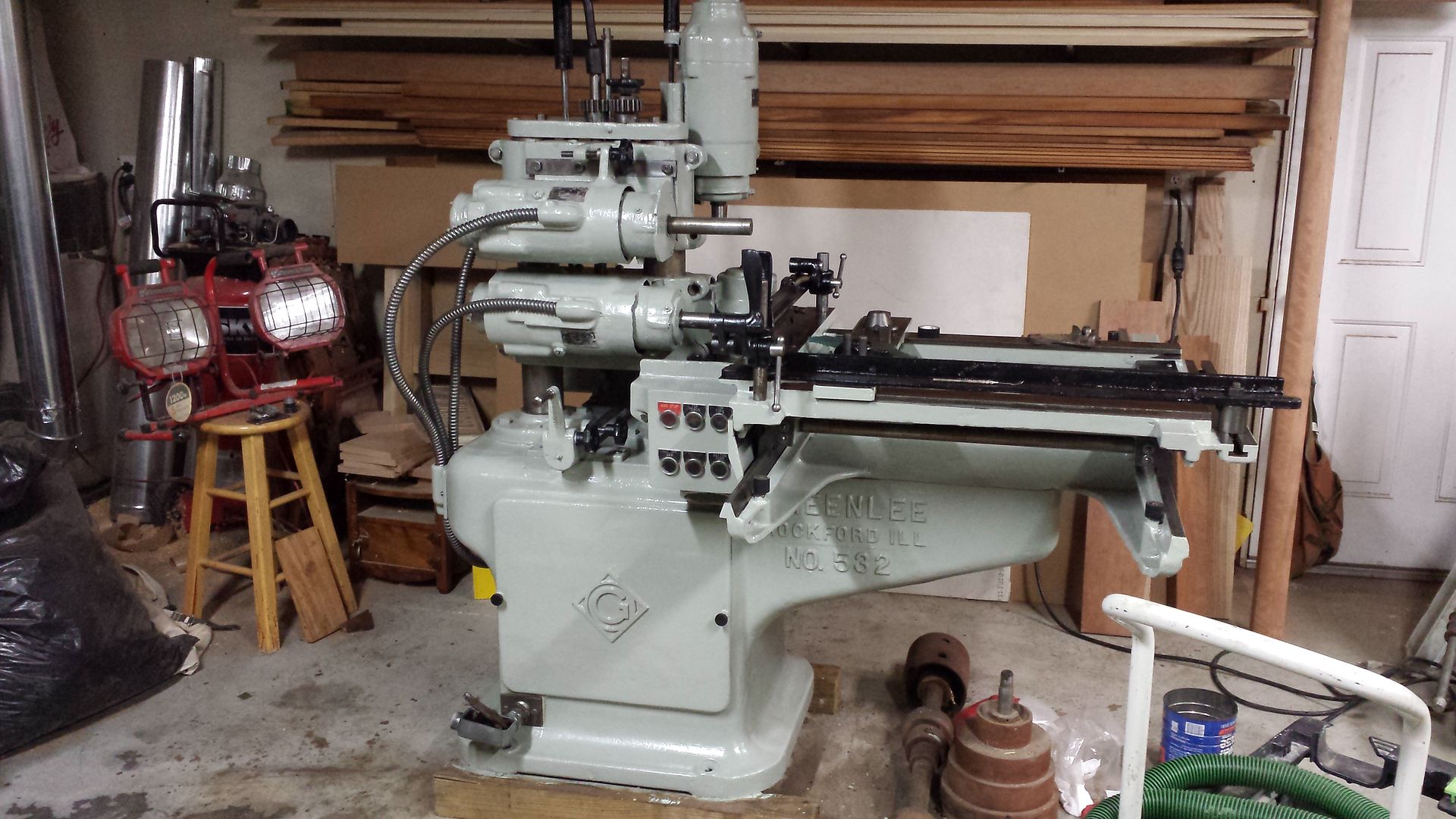

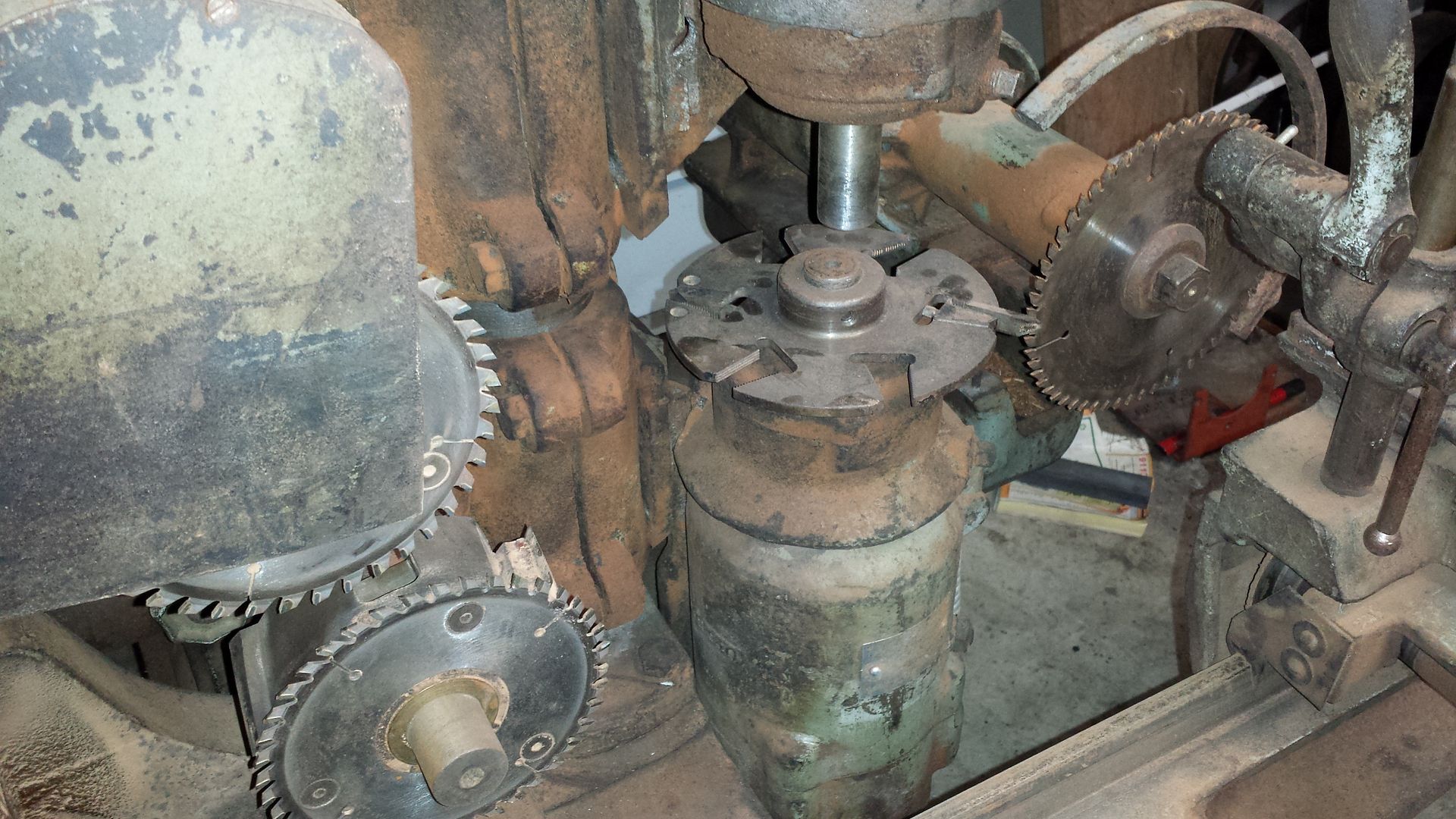

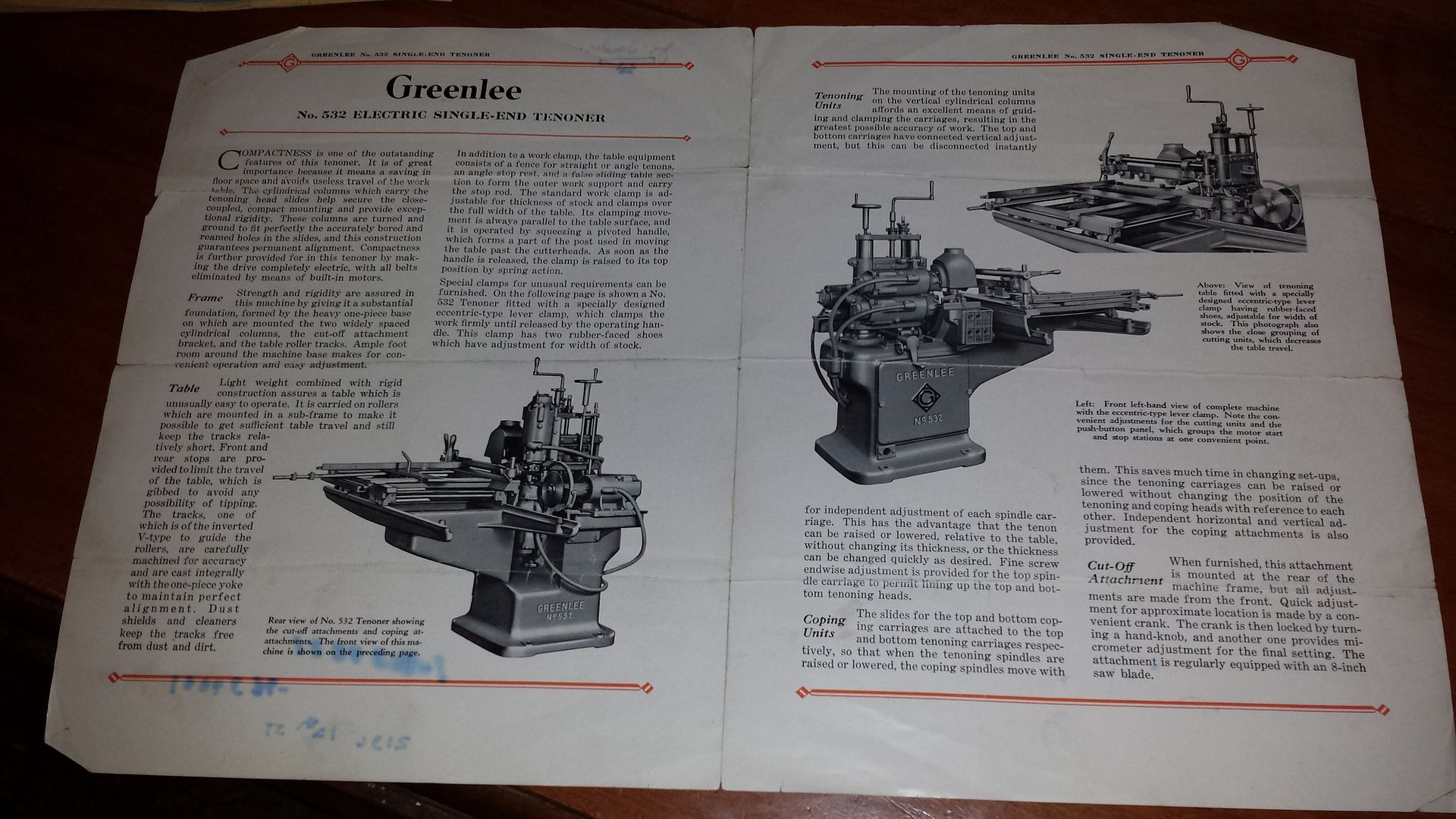

This machine was made in 1948, has 5 heads (upper and lower tenon heads, upper and lower cope heads and a cut off saw) and the table has 48" of travel allowing for a 24" wide piece to be worked. Machine weighs about 2600 pounds.

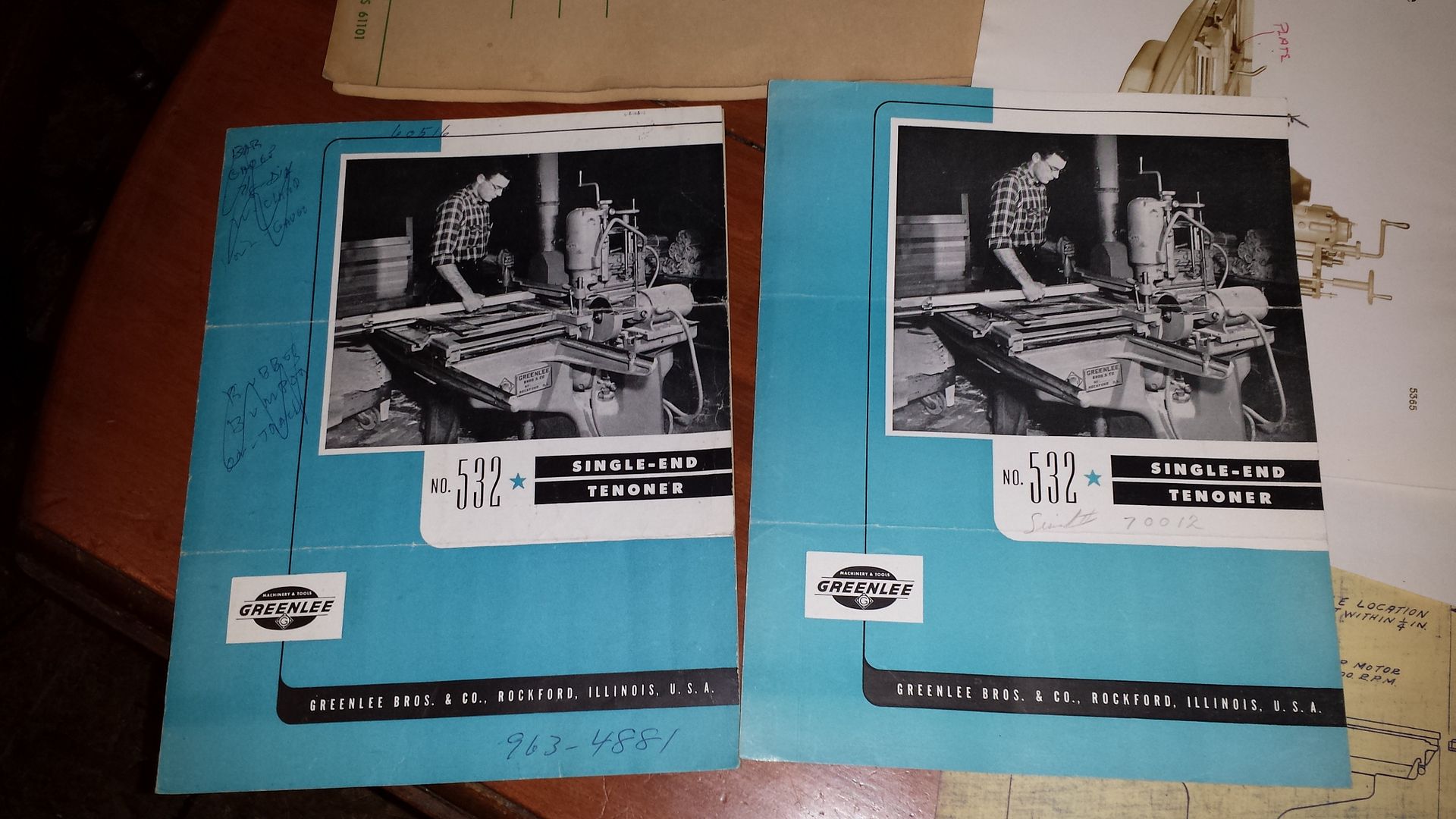

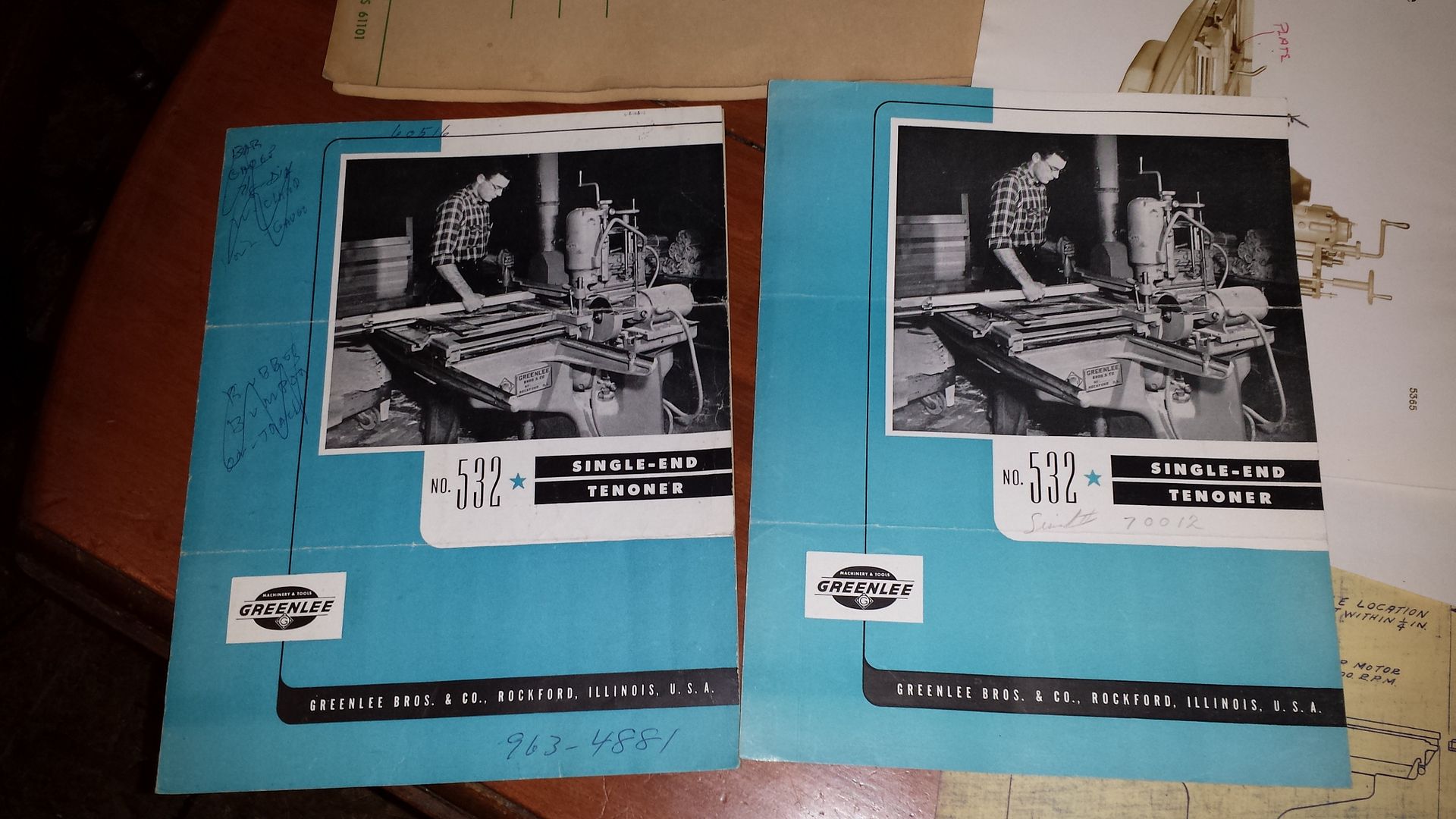

I also got a ton of glossy literature with it, a couple shop drawings from 1948 and a complete parts list and build sheet.

I have been looking for a single end tenoner for quite some time. They were always too far from home or not what I was looking for.

This machine required a 500 mile round trip to the auction and a 22 hour day.

This machine was made in 1948, has 5 heads (upper and lower tenon heads, upper and lower cope heads and a cut off saw) and the table has 48" of travel allowing for a 24" wide piece to be worked. Machine weighs about 2600 pounds.

I also got a ton of glossy literature with it, a couple shop drawings from 1948 and a complete parts list and build sheet.