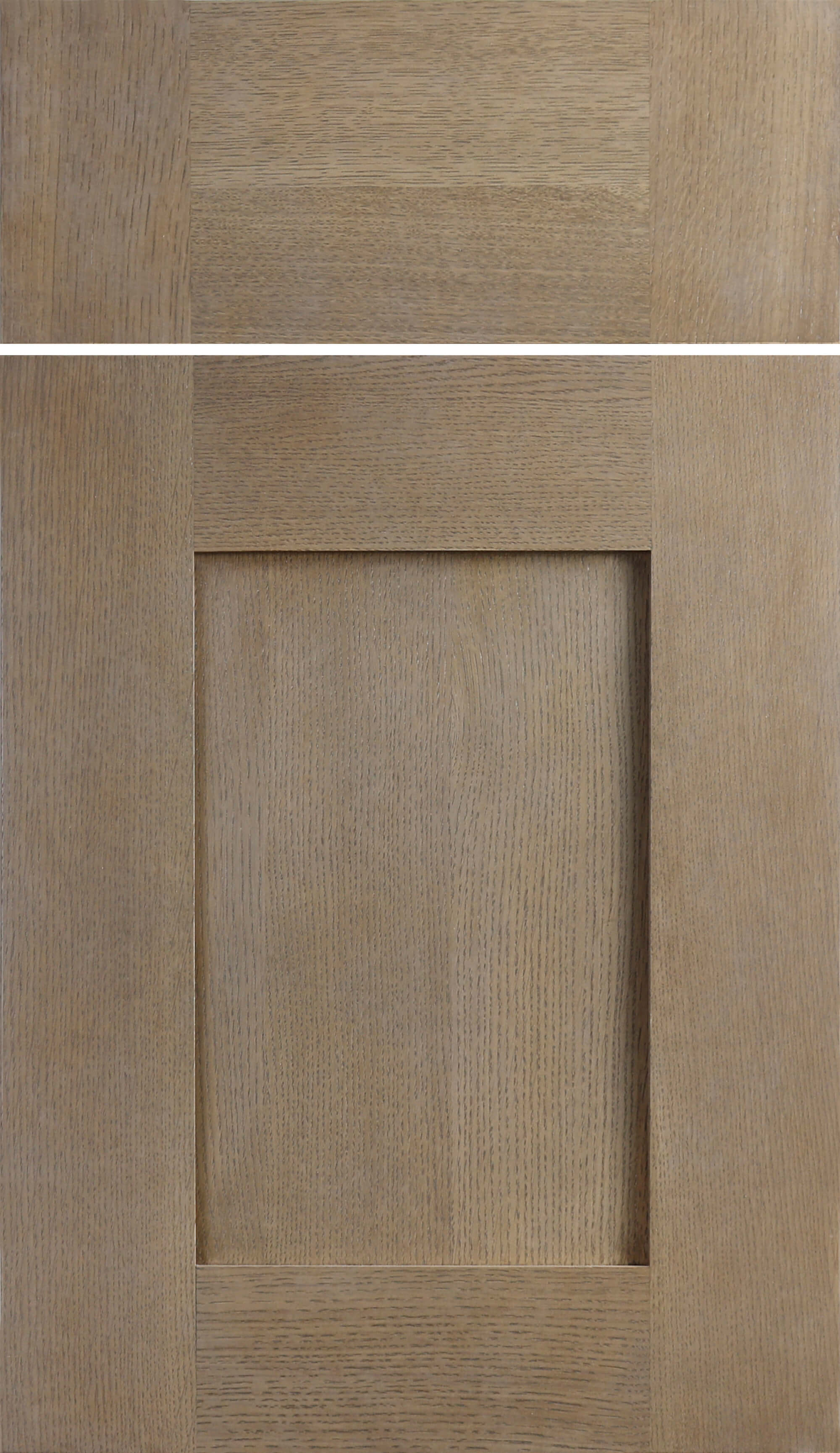

Here is some additional data from another cabinet maker. The width of the micro frame is 25mm (0.984252") vs. 95mm (3.74016").

https://www.handmadekitchens.co.uk/blog/glossary/shaker-kitchen-doors-and-flat-kitchen-doors/

Micro shaker

Our standard shaker doors are constructed with a 95mm thick frame. If you’re looking for a modern design, but still fancy the shaker look, then why not go for our micro shaker doors, with a thin 25mm frame around the recess – all the principles of shaker design but with a subtly modern twist.

Also from this cabinet maker:

https://superiorcabinets.ca/trends/slim-shaker-cabinets-are-not-a-trend/

Slim Shaker in Wood [The Eryn Door]

Thicker Door:

7/8” overall door thickness, whereas most cabinet doors are 3/4” thick.

Reveal:

Has a 1/8” recessed depth panel.

Natural Only with Black Walnut: The Eryn Slim Shaker is only available in a Natural Finish with Black Walnut Wood. For other available wood species, a stain will need to be selected.

Not Available in Hickory: The Eryn Slim Shaker is not available in Hickory Wood.

Not Available in Rustic Wood: Due to the construction on this door, rustic is not available. This is because the center panel is made of wood veneer and not solid wood.

Slim Shaker in One Piece MDF [The Darby Door]

Reveal: Has a 1/16” depth recess.

Made of One Piece: This is fabricated on a CNC router, great for environments with low humidity and dramatic seasonal changes, as cracking at door joints due to seasonal changes will not occur.

This would require that I obtain 1" thick stock, to get the 7/8" thickness x 25mm width.