lshah72414

Member

- Joined

- Nov 10, 2016

- Messages

- 144

Hi all,

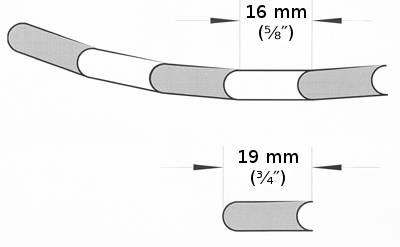

Will be making a cedar chest for the wife. I have figured out everything except the top. On the front, the top has a rounding to it, the chest will be 5 foot long. I am not sure how to make the rounding that long and consistent. I have a 1040 router, but not sure what type of bit to use. Any suggestions would be helpful. Please see photo down below.

Thank you

Will be making a cedar chest for the wife. I have figured out everything except the top. On the front, the top has a rounding to it, the chest will be 5 foot long. I am not sure how to make the rounding that long and consistent. I have a 1040 router, but not sure what type of bit to use. Any suggestions would be helpful. Please see photo down below.

Thank you