WastedP said:

It looks like your tabletop mounting plates are an off-the-shelf item. Who makes them and where can I buy them so I don't spend hours fabbing my own?

They are indeed a commercially available item. They come from FastCap. They are called Stealth Speed Brace. They're about 1/4" thick and 12" or 16" long. You can get them up to 24", but those are thicker 3/8" I think. The 12" are less than $15

[member=44099]Cheese[/member] There are on-line calculators to figure it out. I think some of them even go to the point of exactly where the radius lands, when the kerfs close. That is most important when the end product is not supported very well. The way I use it, permanently glued to a structure, that isn't important.

Telegraphing depends on a couple of factors, the distance between cuts and the depth of cut, for this application.

You kind of have to balance it, to some degree. The more cuts you have, obviously takes more time, but it also weakens the panel. That part only matters as far as handling, until it is attached.

The depth matters in the tension that is left in the sheet. The more you have to force it to bend, the smoother the curve. You are stretching the outside, so it flows. The deeper the kerf, the more they act like a hinge, this causes the facets that "telegraph". When it is minimal, you can sand that away, to some degree anyway. That also has an effect on how hard it is to bend. Some of this depends on the strength of the structural core. If the core is not strong enough, the plywood will tend to straighten it, instead of the other way around.

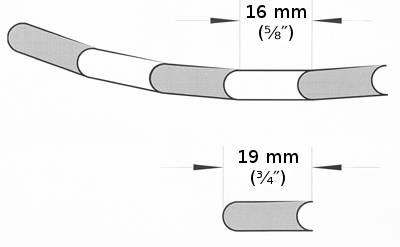

The other factor is, what happens next? (IE will it matter) It the case of this specific job, it doesn't. The round one gets tile applied to it, on site. The elongated one gets the half-round strips, just like the job from a week or so ago. It gets painted this time though. More care must be taken, when it gets laminated or veneered. Shiney makes it more obvious, so it has to be smoother.

Most of the time (for me) the radius is larger, 24" or more. Kerfs spaced at 1" and around .650"-.700" deep will wrap around that just fine. I test for wider spacing on larger radii, say over 48", just because it's faster to produce.