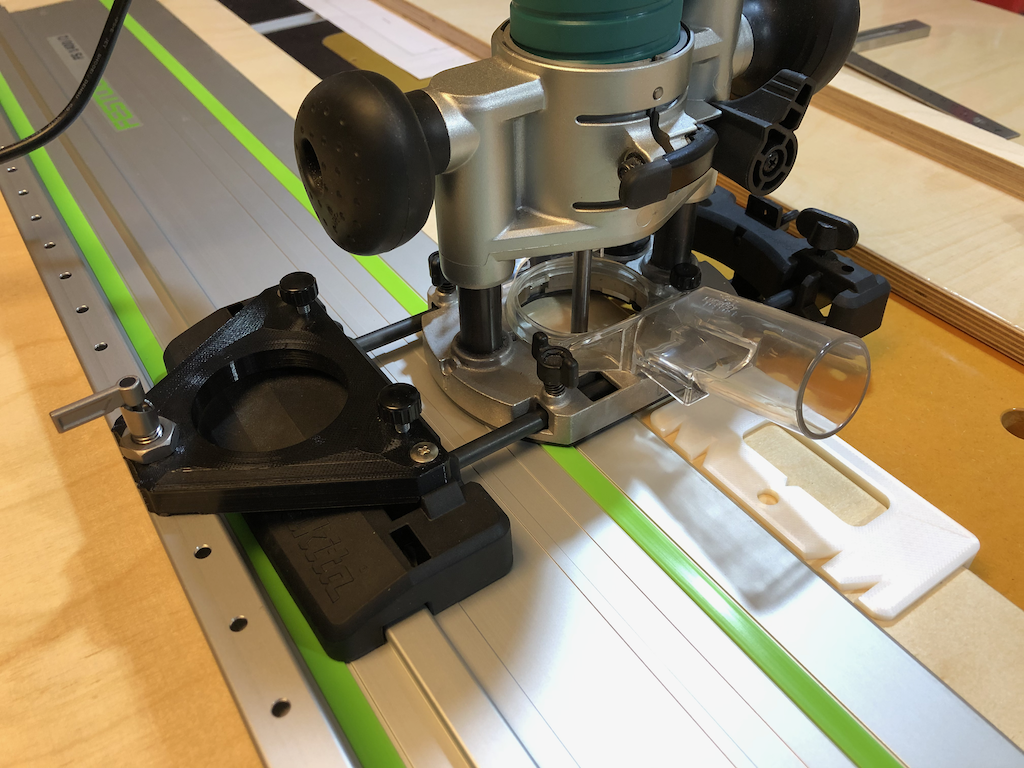

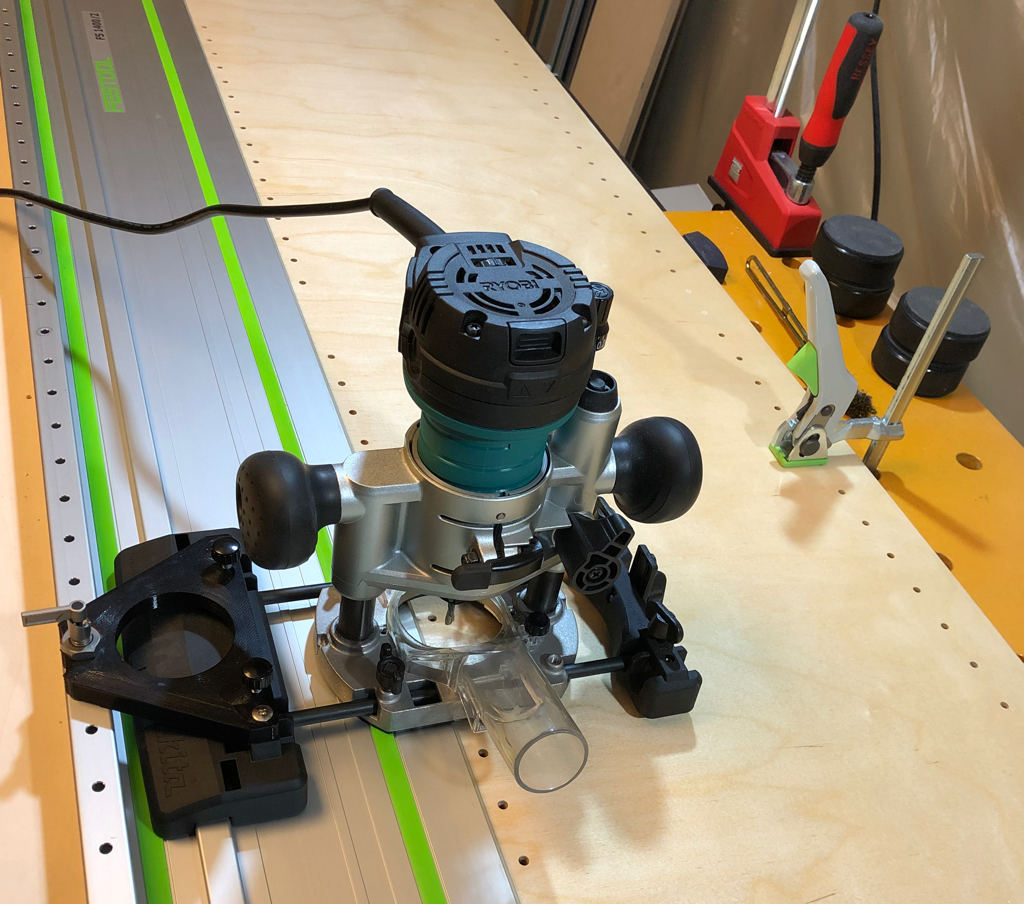

I'm curious if anyone has done any development on a 3d printed LR 32-esque jig? I've checked Thingiverse and came across one for the 1010, has anyone tried it out? Are the 1010 and 1400 bases the same dimensions? I'm yet to see one pop-up on Etsy, but the scene there seems to be thriving with accessories for the MFT, domino, dust ports, etc...

I've been considering building something like this jig that was posted here in 2009: www.festoolownersgroup.com/festool-jigs-tool-enhancements/el-cheapo-diy-... but before I do that, I'm wondering if anyone has came across a good 3d printed solution? With the price point of the LR32 system and needing to purchase a separate "holey" rail for the system it's $680 (not including a router) and thus off-putting to a lot of potential users. I think there's a big market for an alternative that uses the standard festool rails with a jig that attaches to the rail.

Cheers,

Matt

I've been considering building something like this jig that was posted here in 2009: www.festoolownersgroup.com/festool-jigs-tool-enhancements/el-cheapo-diy-... but before I do that, I'm wondering if anyone has came across a good 3d printed solution? With the price point of the LR32 system and needing to purchase a separate "holey" rail for the system it's $680 (not including a router) and thus off-putting to a lot of potential users. I think there's a big market for an alternative that uses the standard festool rails with a jig that attaches to the rail.

Cheers,

Matt