Hi folks,

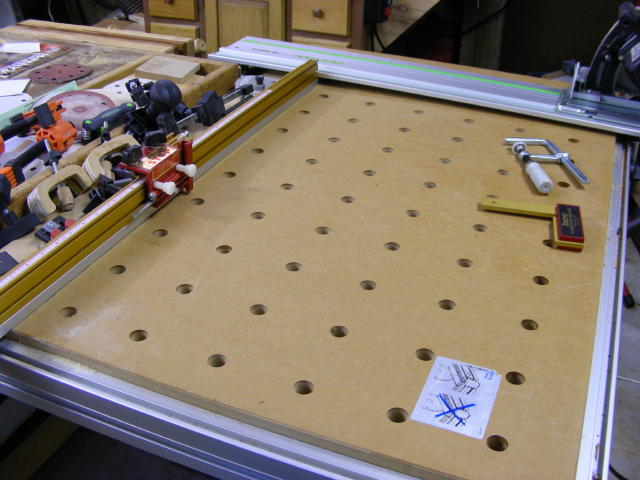

This is a modification to the way I attached the Incra incremental track to my MFT fence.

I could swear there was an earlier post where Corwin put forth the original idea but I cant find it so I'm creating a new post.

The problem was with the "no modification" way of installing the track using existing slots and tracks, it sat on top of and slightly in front of the MFT fence. This worked just fine but anything smaller than 7/16 thickness could slip under it and be registered off the MFT fence.

Anyway I decided a few small holes drilled in the MFT fence wouldn't hurt anything so here's what I did.

First I had to shim the MFT fence so that it was sitting square...it hadn't been.

Once that was done I positioned the track where I wanted and drilled a few small holes for screws. To position the track, first I hooked the guide rail onto the tab of the guide rail support so it was sitting in its 90? position, then I butted the track right up against the guide. I did this to give me a ready reference of 90? when I use the table to square oversize boards...more on that in another post.

Then lastly, using my square, I attached the track. I'm much happier with this installation.

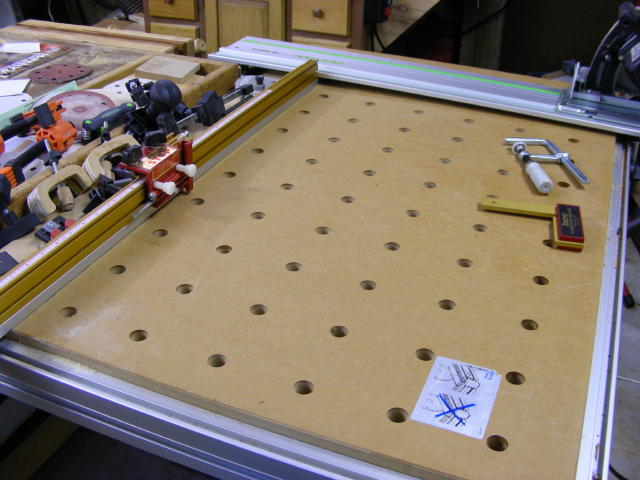

This is a modification to the way I attached the Incra incremental track to my MFT fence.

I could swear there was an earlier post where Corwin put forth the original idea but I cant find it so I'm creating a new post.

The problem was with the "no modification" way of installing the track using existing slots and tracks, it sat on top of and slightly in front of the MFT fence. This worked just fine but anything smaller than 7/16 thickness could slip under it and be registered off the MFT fence.

Anyway I decided a few small holes drilled in the MFT fence wouldn't hurt anything so here's what I did.

First I had to shim the MFT fence so that it was sitting square...it hadn't been.

Once that was done I positioned the track where I wanted and drilled a few small holes for screws. To position the track, first I hooked the guide rail onto the tab of the guide rail support so it was sitting in its 90? position, then I butted the track right up against the guide. I did this to give me a ready reference of 90? when I use the table to square oversize boards...more on that in another post.

Then lastly, using my square, I attached the track. I'm much happier with this installation.