You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

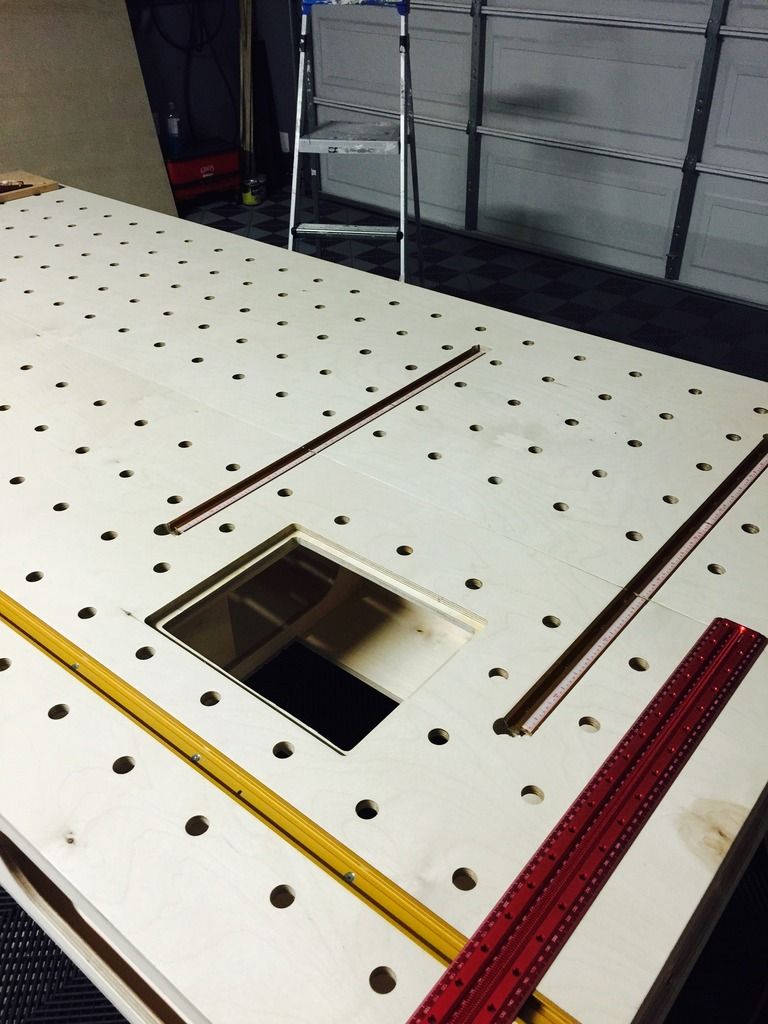

My Paulk Workbench.

- Thread starter topcat

- Start date

Love it. I've had the plans for a while and hope to build one soon.

Did you follow the plans, or improvise at all? Always wanting to learn from others experience...

Did you use pocket screws to join it together, or wood screws as Ron did on his "total station?"

How did you make the holes? 3/4 or 20mm?

Again nice job and thanks for sharing.

Did you follow the plans, or improvise at all? Always wanting to learn from others experience...

Did you use pocket screws to join it together, or wood screws as Ron did on his "total station?"

How did you make the holes? 3/4 or 20mm?

Again nice job and thanks for sharing.

Love it. I've had the plans for a while and hope to build one soon.

Thank you. It was a fun project to build and I learned a few things doing it. For one I'd invest in a really good template bit for pattern cutting. I learned the hard way and was trying to get by with a router guide plate I have that really isn't suited for pattern cutting IMO. I would also make templates and keep them for future builds. I have several friends and family members that want to build one now. It is a very good workbench and I have no complaints about it's design. I've seen others use 3/4" plywood and in no way do I think this is necessary for strength. I debated using it myself but decided in the end to just stick to the plans. I'm glad I did! It is relatively heavy and I wouldn't want the added weight of thicker plywood. It is SUPER solid and it doesn't budge a bit when you put any level of force on the thing. It's nearly impossible to get it to move unless you give it a really solid nudge.

Did you follow the plans, or improvise at all? Always wanting to learn from others experience...

I followed the plans for most if not all of it. The only thing I changed really was the lumber (I used 12mm Baltic Birch), the dog holes are 20mm not 3/4" and the T-Tracks are not just the standard T-Track but are the Incra T-Track with integrated measuring scale. I do plan to add a power strip into the bench, an on/off switch for the router lift and a coat of varnish.

Did you use pocket screws to join it together, or wood screws as Ron did on his "total station?"

I used pocket holes as the plans specify. The bottom calls for wood screws as it would be difficult to use pocket screws since you'd have to have a right angle driver to attach the bottoms. I didn't glue the bottoms on like the plans called for since I wanted to be able to remove them in the future if i were to change anything internally.

How did you make the holes? 3/4 or 20mm?

I used my OF1400 on a rail and a 20mm Festool bit. I marked all the hole locations on the top using traditional pencil markings. I considered using my LR32 and drilling them on 96 mm centers but I didn't want to spend the time calculating any changes this might involve with T-Track, miter or router plate placements. I know it wouldn't have taken that long to change this but I'm not using the surface of this like I use my MFT/3. I do feel confident that my holes are close to good enough to use rail dogs and qwas dogs to make nearly precise cuts. Would I chance this on a precision piece I was cutting? No Way! CNC or precise cuts with the LR32 and dogs could lead to a perfectly square dog hole pattern. I just didn't see this as a game changer.

dlu

Member

Were you able to see the photos? I can't.

- Joined

- Feb 22, 2016

- Messages

- 2,858

Sharky said:Amazing job Topcat!!!

Maybe I'm abusing your patience, but, will U share the plans with me? [embarassed]

I think the person you are abusing is Ron Paulk, go to his website and buy a set of

plans of your own.

They are very reasonably priced and Ron put a lot of work into developing them.

If you can't afford $10 for the plans where will you come up with the money for

the lumber to build the bench?

http://stores.modularmarket.com/paulk_homes/

Bob D. said:I think the person you are abusing is Ron Paulk, go to his website and buy a set of

plans of your own.

They are very reasonably priced and Ron put a lot of work into developing them.

If you can't afford $10 for the plans where will you come up with the money for

the lumber to build the bench?

http://stores.modularmarket.com/paulk_homes/

Wouldn't he have to know that Ron Paulk was the original creator of this workbench and offered the plans for sale? (No reason to act like a jerk about it)

If you can't see the pics, right click on one and you should be able to open it in another window to view. Here is the first pic

Attachments

Similar threads

- Replies

- 1

- Views

- 844

- Replies

- 14

- Views

- 338