Michael Kellough said:Dowels are good if you can work very precisely. The Duo dowel machine is very nice but no wiggle room.

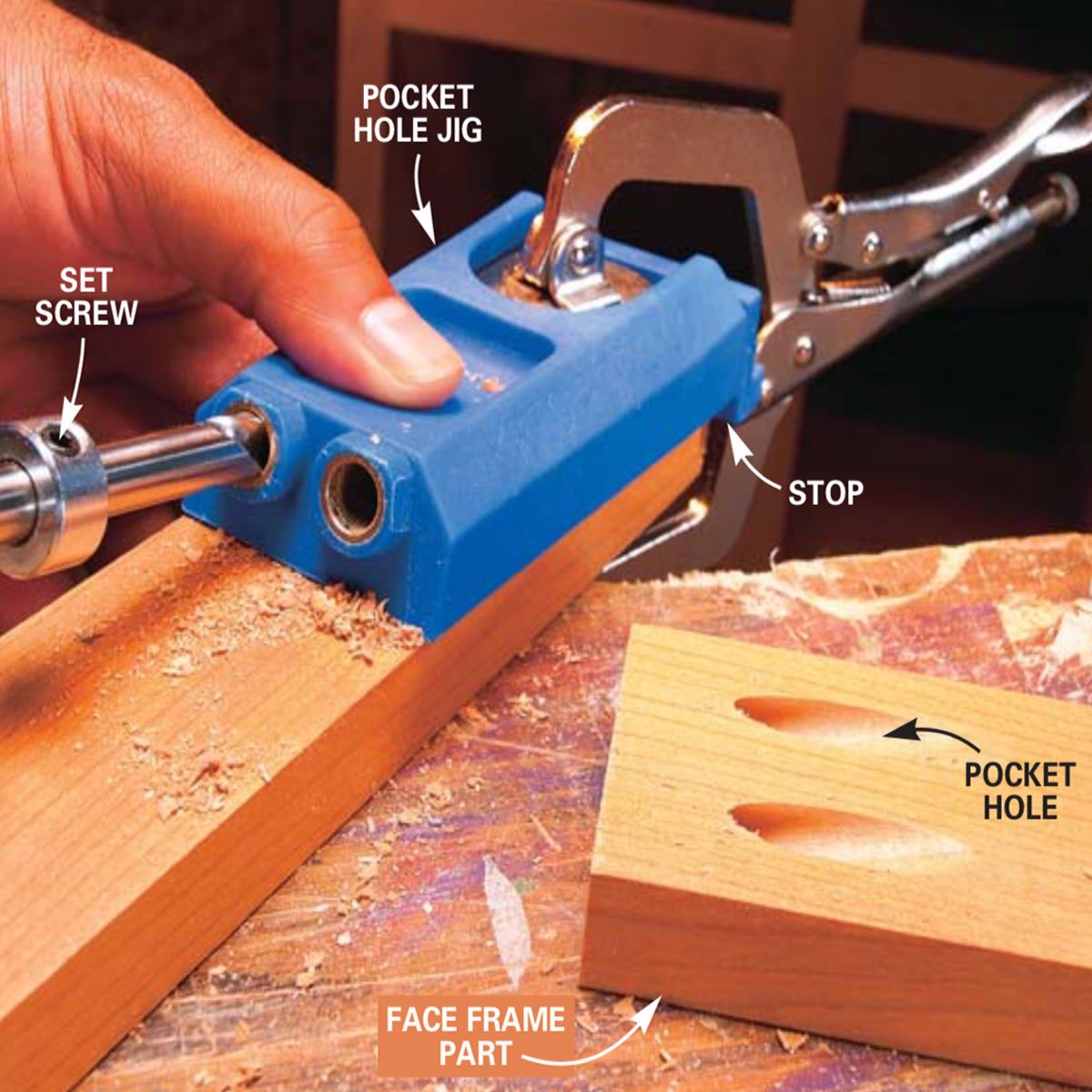

Pocket holes can be used on material as thin as 12mm, if you’re careful setting cutter depth.

Dominos (4mm size) can be used on material as thin as 10mm if you add a shim plate (5mm or more) to the fence.

I went for the Mafall DDF40 in the end as it covers joining and drilling. So far, tests are promising.