#Tee

Member

- Joined

- Jul 28, 2014

- Messages

- 786

neilc said:Not sure you will be pleased with sanding the plexiglas to give you a frosted look. I have tried sanding aluminum to give a brushed look and was never happy with the look, and I think the same could be true with the plexiglas. Might want to try on a scrap from the Hardware store first.

Reeded glass would look great in those doors! So many cool patterns you can custom order in glass that you might want to consider to really make a 'statement' with the doors.

Great project - please share photos as you progress with them.

neil

[/quote

I concurr. Reeded glass looks great as would etched glass or sandblasted/beadblasted glass. These doors will need to be washed from time to time and plexi or acrylic is prone to scratching. Real glass isn't that much more expensive than plastic.

tjbnwi said:The acrylic should come with a barrier film, don't remove until after painting.

6/4 maple planed to 1-3/8.

Tom

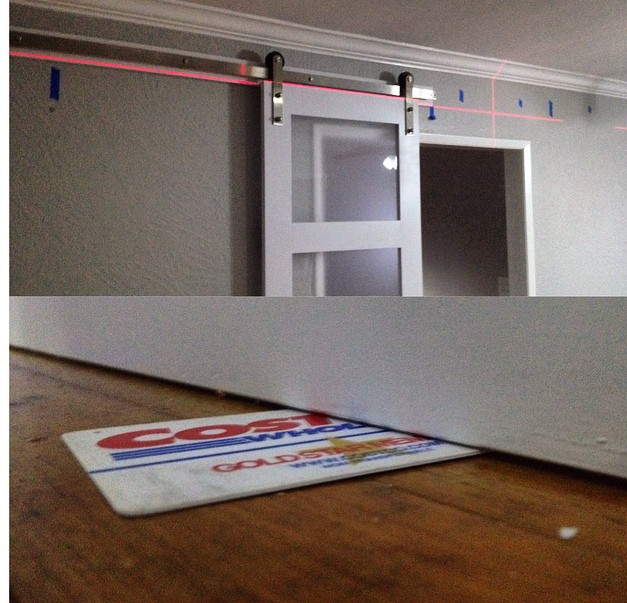

#Tee said:thanks for all the suggestion guys! another question guys?? with all these barn door applications...i get the top slides but the bottom just flops around? how do you keep that from scraping the baseboards? [embarassed]