joiner1970

Member

- Joined

- Jun 13, 2007

- Messages

- 3,222

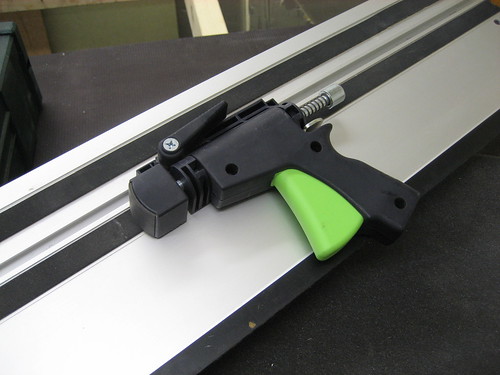

REVIEW OF FESTOOL FS-RAPID/1 489790

The FS-Rapid comes as a set with the main gun unit and a small stop which acts as the other end of the clamp. The FS-Rapid is made of strong plastic with some metal components and it has rubber pads on the parts that clamp to the material, this protects the edges and also stops the clamps slipping. The gun part of the FS-Rapid works just like a caulking/mastic gun. When you squeeze the trigger the piston moves and clamps the material, when you want to release the clamp you just press the small metal lever at the rear of the gun which releases the pressure on the clamp.

To fit the set to your rail you just loosen off the black levers on the gun and the stop and just slide the t-nuts into the t-slots on the underside of your rail slide them to where you want them then lock in position by just turning the levers until they are tight on the rail.

Below you can see the FS Rapid fitted to the rail

I originally bought my FS-Rapid to use for cutting down doors that are still hanging , this is very difficult to do with the standard clamps as you cannot use a clamp on the hinge side of the door. With the FS Rapid its easy just set the clamps to just over the door width then place the rail where you need to cut the door and squeeze the trigger to fix the rail in place. Now use your TS55/75 to trim the bottom of the door to the correct height. Always make sure the door cannot move while you are cutting and be careful that the saw stays on the rail.

Here you can see the rail clamped to the door

Since I have had the FS Rapid I have found other uses for them another one is for routing. Let's say you need to rout lots of slots or grooves across a sheet and you want the slots to be the same length and parallel then use the FS Rapid and two Kickback stops (FS-RSP). The Kickback stops will set the length of the slots/grooves and if you use the Fs Rapid to clamp the rail you know it will be the same distance in from the edge of the material you are routing every time.

A good feature on the FS-Rapid is that the gun part of the clamp can swivel until it is flat to the rail this is handy for transporting the rail and for when you have limited space to work in where the gun would be in the way in the normal position.

This picture shows the gun folded flat

All in all I have found the FS-Rapid a very handy addition to the Festool rails and recommend them to anyone and I am sure other people will find different uses for them.