nydesign

Member

- Joined

- Jul 24, 2011

- Messages

- 144

I'm building a 48" dining table while doing some work on my parents house. There's a small one car old garage I'm working in,

it's really too small to work effectively but I'm dealing with it [unsure]

Sorry for the cell phone pics it's the only camera I had.

First shot is gluing up the boards for the top, they came S4S so I did not have to do any milling.

The next day I traced a 48" circle and cut around it with the jigsaw.

I made a lay out of the legs using the legs. I'm much better designing with models or the actual piece.

This let me figure out the angle I wanted to use, where the bracing would go and how it all looked under the top.

I used the domino with #8 by 50mm domino's to assemble the legs and clamped.

I took the legs already made and placed the opposite legs over them to make sure they would be the same size.

This also let me cut the braces without having to worry about measuring perfectly.

I began by gluing the cross pieces to the completed leg set.

Because the dominos coming off the cross pieces were at an angle I just placed the legs against the cross pieces and marked where they hit the legs.

I used the first width setting on the cross piece and the second width setting for the leg.

Glue up showing detail of the angled blocks to support the clamps.

Detail showing position of domino holes

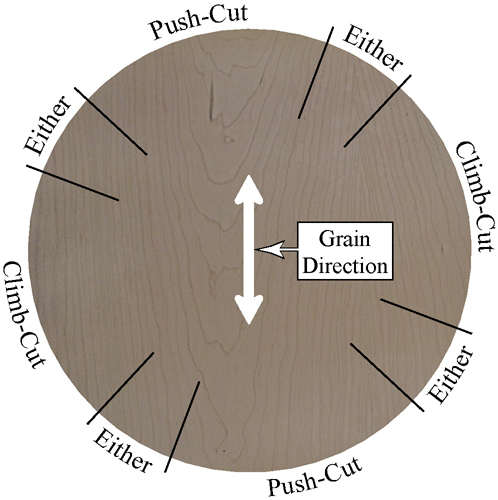

Jig I made up to rout the final circle for the top. Here's where things went wrong.

I used a longer 2.5" straight bit that stuck out beyond the routers plunge capacity.

I thought no problem, I'll just rout from the outside of the circle instead of plunging like I normally do.

I set it up so it would take 1/16" off, found a spot on the top where the bit was not touching the wood and began the cut.

As soon as the bit hit the wood the router jumped out of my hands and took off around the table by itself. I was not prepared for this at all,

fortunately it was not going fast, also fortunate was that the jig was held in place by a long screw and prevented the router from going

anywhere else. The unfortunate part was the bit chewed up the sides real good, and one side of the bit broke [embarassed]

New bit lasted 2 seconds.

ouch!

ouch again.

After getting a shorter 1.5" bit I routed the top again by plunging the bit 1/8"-1/4" at a time.

Rounded over the legs as a start and sanded the top once.

Top after sanding with 80 grit Rubin. Next is more sanding, I might round over the legs some more and the top.

I'm going to try finishing the table with 'Old Masters' gel polyurethane. I've not used it yet, I'm going to try some samples tomorrow.

thanks for looking.

- J

it's really too small to work effectively but I'm dealing with it [unsure]

Sorry for the cell phone pics it's the only camera I had.

First shot is gluing up the boards for the top, they came S4S so I did not have to do any milling.

The next day I traced a 48" circle and cut around it with the jigsaw.

I made a lay out of the legs using the legs. I'm much better designing with models or the actual piece.

This let me figure out the angle I wanted to use, where the bracing would go and how it all looked under the top.

I used the domino with #8 by 50mm domino's to assemble the legs and clamped.

I took the legs already made and placed the opposite legs over them to make sure they would be the same size.

This also let me cut the braces without having to worry about measuring perfectly.

I began by gluing the cross pieces to the completed leg set.

Because the dominos coming off the cross pieces were at an angle I just placed the legs against the cross pieces and marked where they hit the legs.

I used the first width setting on the cross piece and the second width setting for the leg.

Glue up showing detail of the angled blocks to support the clamps.

Detail showing position of domino holes

Jig I made up to rout the final circle for the top. Here's where things went wrong.

I used a longer 2.5" straight bit that stuck out beyond the routers plunge capacity.

I thought no problem, I'll just rout from the outside of the circle instead of plunging like I normally do.

I set it up so it would take 1/16" off, found a spot on the top where the bit was not touching the wood and began the cut.

As soon as the bit hit the wood the router jumped out of my hands and took off around the table by itself. I was not prepared for this at all,

fortunately it was not going fast, also fortunate was that the jig was held in place by a long screw and prevented the router from going

anywhere else. The unfortunate part was the bit chewed up the sides real good, and one side of the bit broke [embarassed]

New bit lasted 2 seconds.

ouch!

ouch again.

After getting a shorter 1.5" bit I routed the top again by plunging the bit 1/8"-1/4" at a time.

Rounded over the legs as a start and sanded the top once.

Top after sanding with 80 grit Rubin. Next is more sanding, I might round over the legs some more and the top.

I'm going to try finishing the table with 'Old Masters' gel polyurethane. I've not used it yet, I'm going to try some samples tomorrow.

thanks for looking.

- J