Packard

Member

A couple of years ago I bought a cheap tile saw for some tile work. I ended up not using it for a couple of reasons.

First, score and snap cutting is much faster.

Second, the saw would cause chipping on the glazed surface that was unsightly. Instead I cut with a good scoring cutter and use a carborundum stone to make the glazed surface perfectly smooth and straight.

But the other day I watched an online video where they used the identical saw as I have and they were ending up with very clean cut edges.

Will a different blade resolve this issue? I’ve only cut about 5 or 6 tiles with the factory blade. If I do buy a new blade, what should I look for?

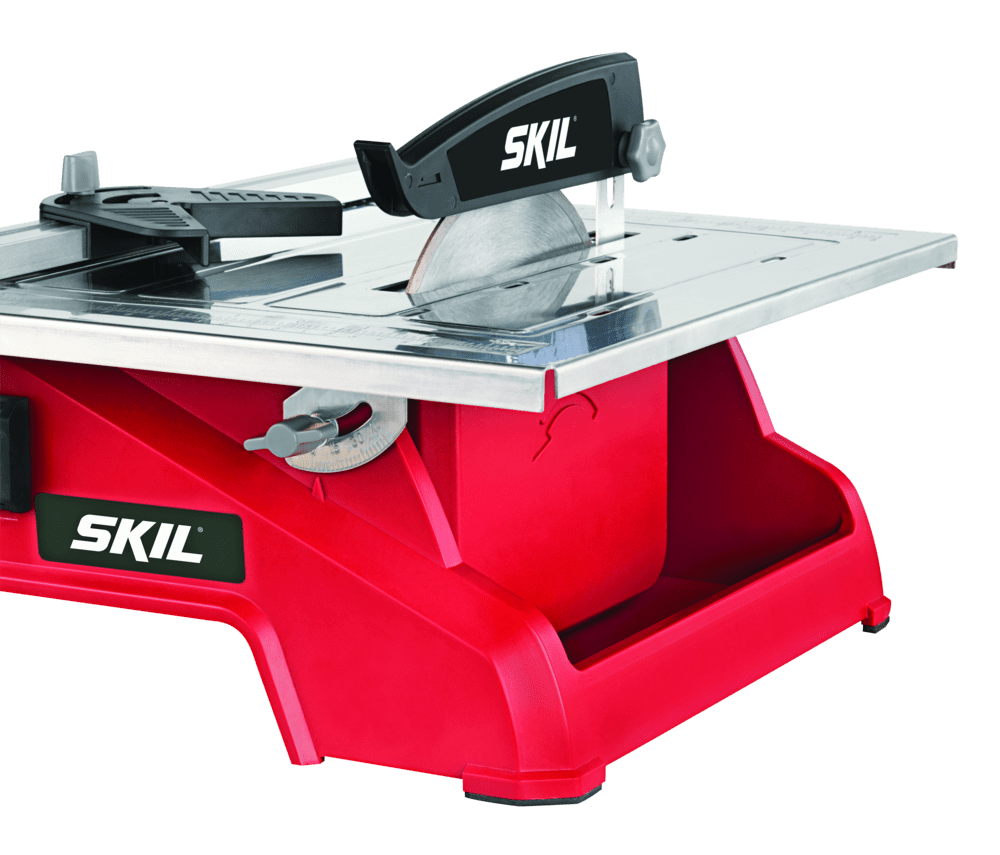

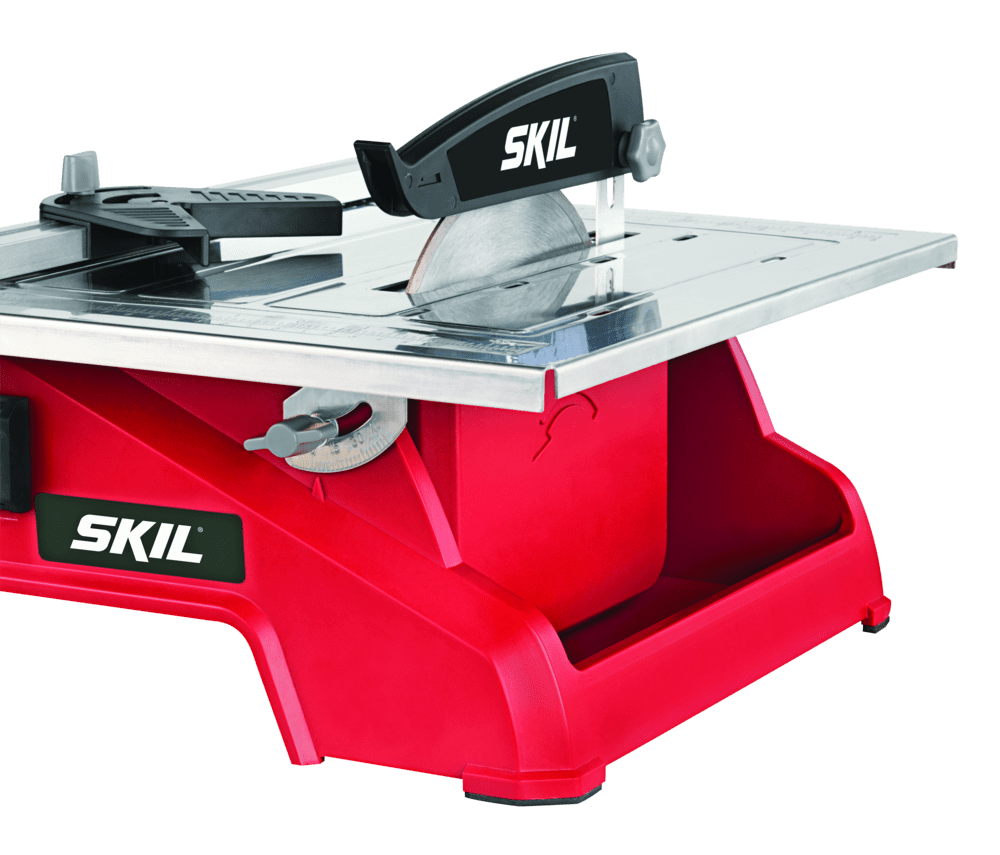

It is a Skil 7” wet saw.

First, score and snap cutting is much faster.

Second, the saw would cause chipping on the glazed surface that was unsightly. Instead I cut with a good scoring cutter and use a carborundum stone to make the glazed surface perfectly smooth and straight.

But the other day I watched an online video where they used the identical saw as I have and they were ending up with very clean cut edges.

Will a different blade resolve this issue? I’ve only cut about 5 or 6 tiles with the factory blade. If I do buy a new blade, what should I look for?

It is a Skil 7” wet saw.