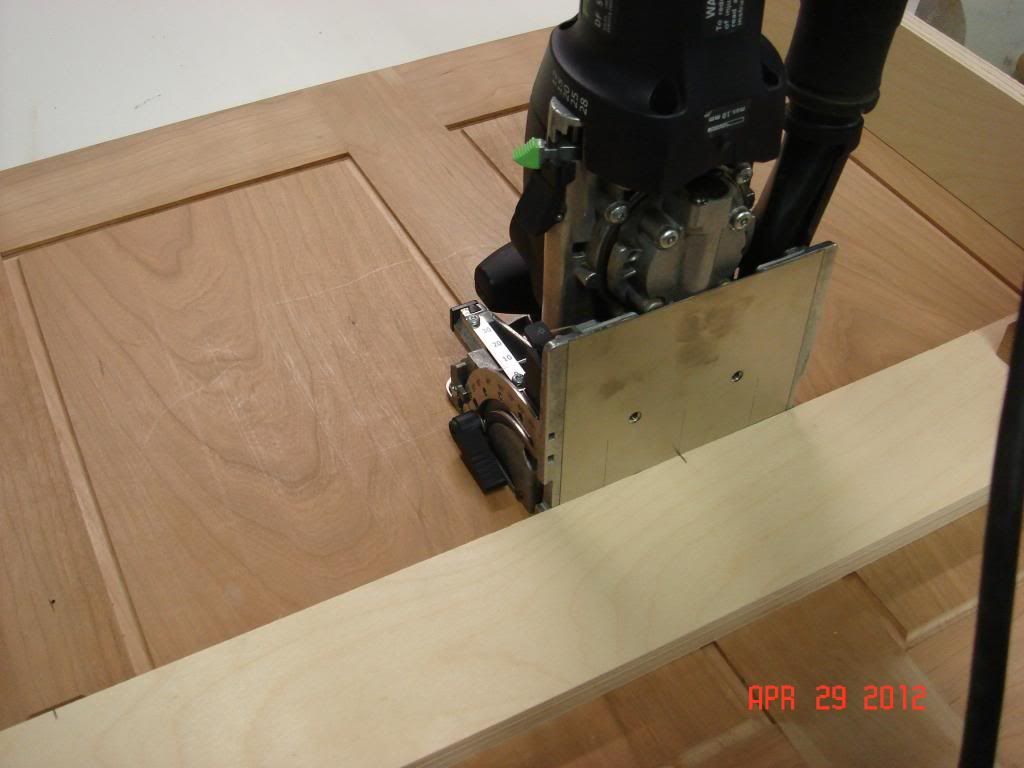

I am trying to build a box using dominos and am having trouble getting the pieces lined up.

When I make a mark for the cut into the edge of the board the center of the cut lines up perfectly with the mark I have made i.e. the cut is perfectly centered on the mark. However when I make the correcsponding plunge into the face of the correcsponding board the cut is not centered on the mark. It is offset by 2 mm.

I am using a shop made "dominplate" and a 4 mm cutter. I realize the fence is adjustable but the "scores" on the bottom of the domino are not. Am I doing something wrong?

Thanks

Fred

When I make a mark for the cut into the edge of the board the center of the cut lines up perfectly with the mark I have made i.e. the cut is perfectly centered on the mark. However when I make the correcsponding plunge into the face of the correcsponding board the cut is not centered on the mark. It is offset by 2 mm.

I am using a shop made "dominplate" and a 4 mm cutter. I realize the fence is adjustable but the "scores" on the bottom of the domino are not. Am I doing something wrong?

Thanks

Fred