Stevenscustomguitars

Member

- Joined

- Jan 18, 2016

- Messages

- 40

Hello,

I'm new to the forum but having been reading lots of posts about the mft, mftc and the Paulk bench etc - some really great threads.

My situation is this - I have a small workshop (6 x 3.5m) that has just been built. I do some guitar work and my main existing tools are a router table, drill press and bobbin sander. And lots of handtools.

I'm about to kit out the workshop with some cupboards and open cabinets and will also start building a new kitchen soon in melamine faced birch ply. I plan on buying the DF500 domino to use in conjunction with a kreg pocket hole jig for all of that.

I don't have a table saw or bandsaw. My only saw, and only current Festool is the TS55 which I love.

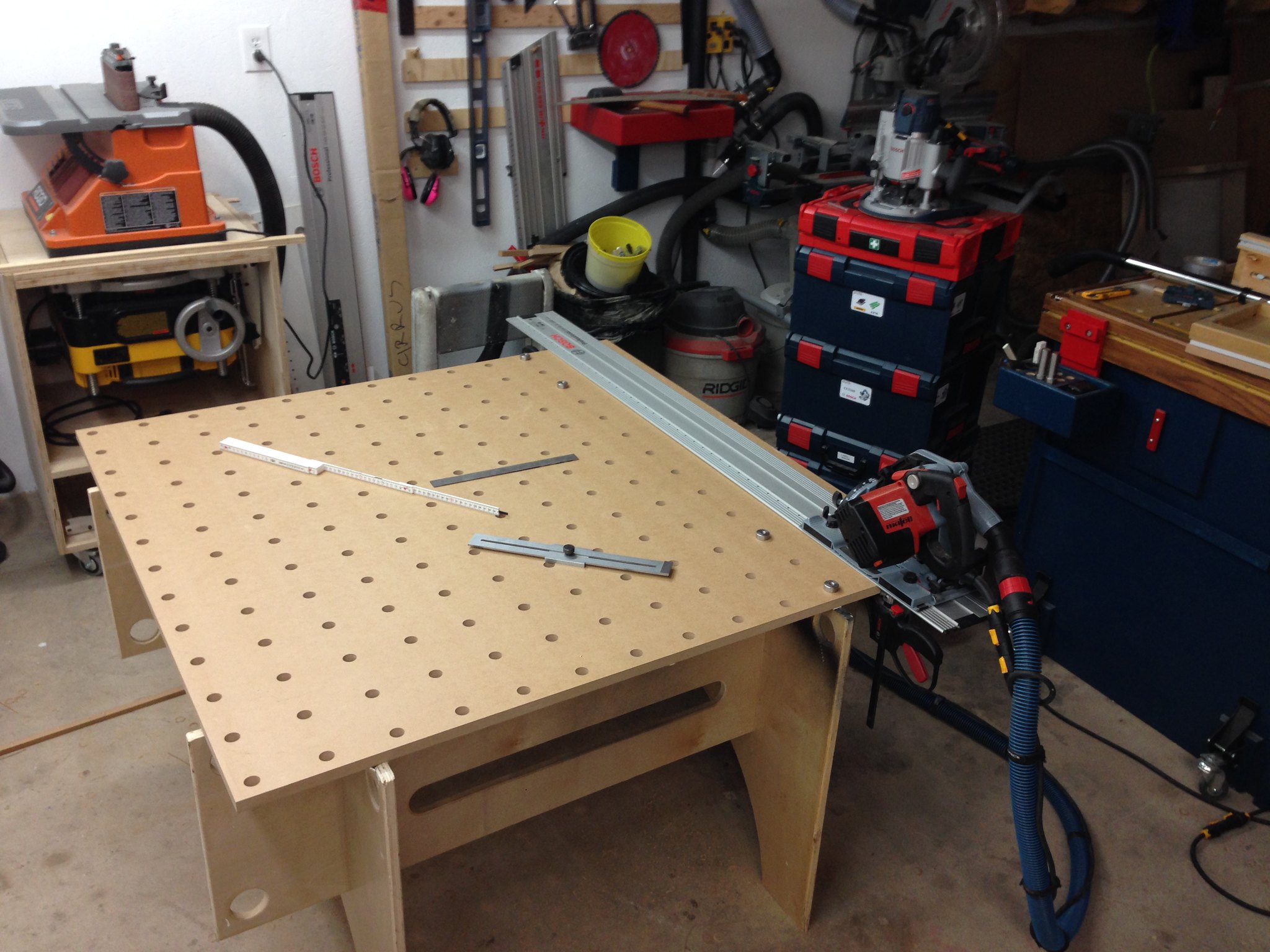

So I'm trying to decide between the MFT3 at a pretty high cost or buying a cnc'ed MF slab (like the one in Steve Olsen's video) for about £45 and building a softwood base for it.

I don't need portability so the pros of the MFT seem to be ease of crosscutting, and routing, and the easy repeatability because of the flag stop. And of course the fact that I could be up and running instantly.

Whereas the slab/DIY gives me a larger work surface, on a sturdier base (built with the domino) that I could hand plane on, I could also fit in t-track vertically in one leg and on an apron if needed I can also design it to fit sortainer cases underneath and have a tool shelf, useful for putting the saw on.

The cons, and the things I need advice on, are that I don't know how easy it is to crosscut accurately using dogs and rail dogs and it won't have any kind of moveable stop built in for repeat cuts which would be very useful. Are there good ways of doing this on a basic Multi function top?

Any advice or photos/ videos would be greatly appreciated.

Cheers

Dave

I'm new to the forum but having been reading lots of posts about the mft, mftc and the Paulk bench etc - some really great threads.

My situation is this - I have a small workshop (6 x 3.5m) that has just been built. I do some guitar work and my main existing tools are a router table, drill press and bobbin sander. And lots of handtools.

I'm about to kit out the workshop with some cupboards and open cabinets and will also start building a new kitchen soon in melamine faced birch ply. I plan on buying the DF500 domino to use in conjunction with a kreg pocket hole jig for all of that.

I don't have a table saw or bandsaw. My only saw, and only current Festool is the TS55 which I love.

So I'm trying to decide between the MFT3 at a pretty high cost or buying a cnc'ed MF slab (like the one in Steve Olsen's video) for about £45 and building a softwood base for it.

I don't need portability so the pros of the MFT seem to be ease of crosscutting, and routing, and the easy repeatability because of the flag stop. And of course the fact that I could be up and running instantly.

Whereas the slab/DIY gives me a larger work surface, on a sturdier base (built with the domino) that I could hand plane on, I could also fit in t-track vertically in one leg and on an apron if needed I can also design it to fit sortainer cases underneath and have a tool shelf, useful for putting the saw on.

The cons, and the things I need advice on, are that I don't know how easy it is to crosscut accurately using dogs and rail dogs and it won't have any kind of moveable stop built in for repeat cuts which would be very useful. Are there good ways of doing this on a basic Multi function top?

Any advice or photos/ videos would be greatly appreciated.

Cheers

Dave