I have the new WP jig and used it several times now (only for 32mm system).

https://www.woodpeck.com/shelf-pin-drawer-slide-template.html

I like that it is higher quality than many of the cheep jigs and that it allows you to use it both with a drill and with a router. The router with the right bit leaves very clean holes. It has worked will for me but I am not entirely satisfied. Here are my concerns:

1. Sawdust tends to stay in the 3/8 holes even when dust extraction is attached to the OF 1400 router. It mainly stays under the guide bushing sides. Maybe it doesn't interfere but I am always worried and take the time to detach the hose from the router and go over the each hole I used in the jig to get everything out. That adds an additional step, which I find pretty annoying. The problem is worse with a drill.

2. I am not entirely satisfied with the accuracy. It might well be user error but it might also be the case that the referencing with the pins and this other thing produces slight errors. This has not been a problem for shelfs or drawer slides. But I do notice it when I do the following: a) Drill first set of holes referencing the front with 37mm offset, b) use jig in perpendicular position referencing from the front to drill two holes in the back. Referencing from the front for holes further on the inside is necessary for drawer slides and I sometimes like to do it in other cases as well. b) Now I should be able to place the jig in the middle of the panel and secure it with pins through the two holes I just drilled to drill a complete set of holes further inside. However, that doesn't work for me because the holes are off by a very small amount. Not sure whether this is clear based on my description. I think the amount of error does not matter for shelfs and drawers slides but it makes the production process more complicated.

EDIT: to be clear, this might be user error. It might also be the case that this type of accuracy just cannot really be achieved with this type of jig.

Today I would probably consider these two jigs as alternatives:

1)

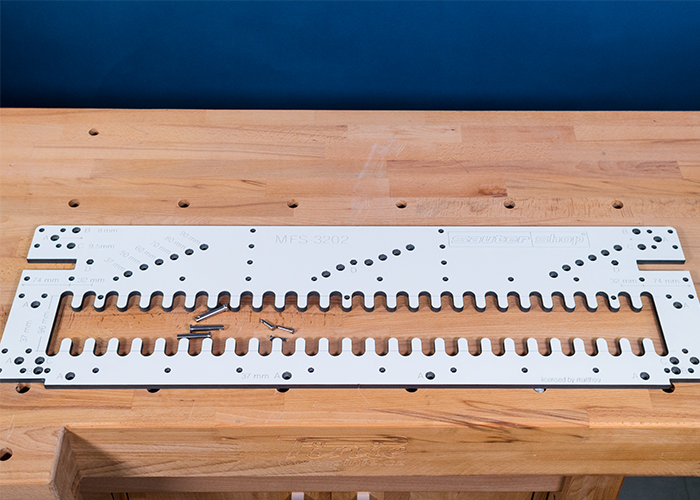

https://www.sautershop.com/system-32-router-template-incl.-dowel-drill-set-mfs3202-2.0?c=15670

The advantage here is that you do not have to lift the router and find the next hole to drill each hole, which makes it much faster in actual use. It might also help with the dust problem. It includes a good router bit, which makes the price comparable to WP. However, the jig is VERY big.

2)

https://www.hafele.co.uk/en/product...n-haefele-ixconnect/0000003e000368e6000a0023/

Only for drills so I would like to see how clean the holes are. But I like the quality of Hafele products and would like to try it. The edge reference thing is attached to the jig and slides up and down, which seems great. Pretty sure it's much faster. Might be hard to get in the U.S. though.

I might still end up with the WP jig. I haven't invested the time to figure out whether either of these two jigs is a better choice but I would certainly take a close look because I am not entirely satisfied with the WP jig.