BarrySumpter

Member

- Joined

- May 11, 2020

- Messages

- 140

A folllow up query from here:https://www.festoolownersgroup.com/...sander-for-all-round-use/msg616052/#msg616052

I've used osmo top oil for our kitchen counter top.

The gorgeous lady was happy with the light colour left after sanding.

Later she wanted it black so was going to use that glue on specks product.

But never got the go ahead. So sold the product.

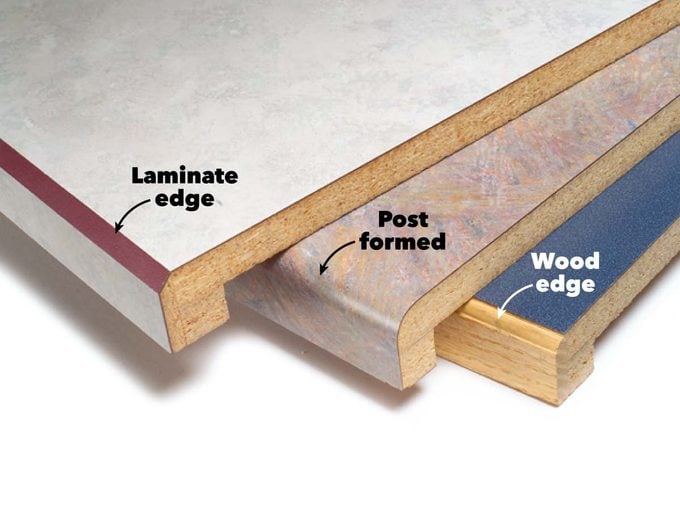

Now she's thinking of laminating the counter top.

Do I need to sand the osmo off before laminating?

Does anyone know if I should laminate the kitchen counter top?

Would i be wasting my time?

Anyone know of a better way to black the counter top?

Thanks in advance.

I've used osmo top oil for our kitchen counter top.

The gorgeous lady was happy with the light colour left after sanding.

Later she wanted it black so was going to use that glue on specks product.

But never got the go ahead. So sold the product.

Now she's thinking of laminating the counter top.

Do I need to sand the osmo off before laminating?

Does anyone know if I should laminate the kitchen counter top?

Would i be wasting my time?

Anyone know of a better way to black the counter top?

Thanks in advance.