I've been meaning to do this for a while and this thread provided the impetus for me to make the prototype.

Caveat: I didn't have a long enough bolt (1/4x20) so I had to use a lower profile clamp than I will for the "production" hold downs.

There is a video at the end of this post showing the clamp in action.

OK, I wanted a hold down which could be inserted and removed without reaching under the table...here it is.

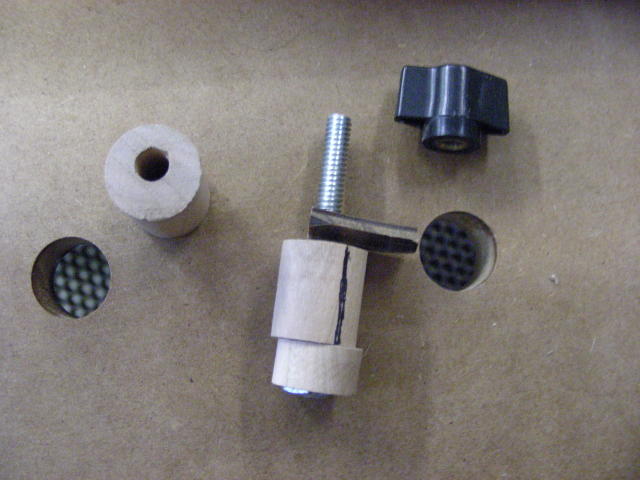

First, I turned a hardwood dowel to 19mm (you can buy a 3/4" dowel...I just didn't want to go out in the Nor'easter we're having)

I cut the dowel to about 2" long and used a 7mm drill bit to drill a hole through the length of the dowel. I positioned the bit so that the hole was offset. (see pic below)

I then cut that dowel so the the body (the part which will go through the MFT) was 7/8" (1" will be fine) which seems to be a good length. The dowel which is to be used as the cam I cut to 1/2" in length. This piece can be longer and probably should be for strength, but my bolt wasn't long enough to accommodate a longer cam. A 1" cam and 1" body would work well and provide good strength.

I counter bored the cam a little to fit the head of the 1/4x20 bolt and inserted the bolt and glued it in place.

Next I created a lever out of a piece of scrap phenolic. It can be any material. I drilled a hole in it and threaded it. I put the body dowel on the bolt and then screwed on the lever. Tightening the lever so that the assemblies was still loose, I aligned the lever so that it pointed at the maximum offset of the cam...then glued it in place with some CA.

That's it, the assembly is complete. Next make a clamp. I used one that I use in T-Tracks but a larger "U" clamp like this Jorgy one would work better...again, my bolt wasn't long enough to make one.

So to use it, you stick in in the hole, rotate the lever until the cam locks the clamp from coming out of the hole, then tighten the thumbscrew. The cam does not tighten in the hole, it rotates and forms a latch to prevent the dowel from coming out of the hole.

So that's it.

View this video to see how it works.