williaty said:

What amazes me is that, as bad as user manuals are, service manuals are often worse! ...

Ummm....Willi....Pal.....Friend....My day-job is writing

Service Manuals! [big grin] [big grin] [big grin]

All kidding aside, I know exactly what you are talking about. Before I went independent, I had this cow-worker that convinced our manager that she was capable of writing hardware manuals (as opposed to software), and was therefore on-par or even better than I was (because I refuse to ever write a software manual).

I was working on a Service Manual for a $500,000 product, and I wanted to see if there was any information I could steal from a sister-product manual. There was a procedure for replacing a stepper motor. The procedure should have been, "take these 3 screws out, and you are done." Instead, the writer had the technician removing the main assembly from the base (1 hour labor), then remove the subassembly from the main assembly (15 minutes labor), and then remove the 3 screws that were accessible the entire time.

That wasn't an isolated incident. The entire manual was written that way. The writer didn't realize that her 10 to 15 words actually amounted to hours and hours of labor. It took 30 seconds to type, but she didn't comprehend what that meant in real life.

When I write a service manual, I physically tear the machine apart in my office or shop. When I don't have access to a machine, I still virtually tear it apart within SolidWorks.

===============================================

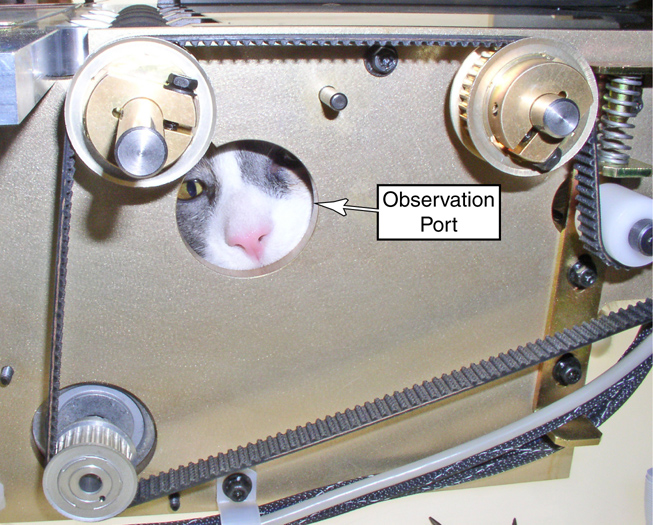

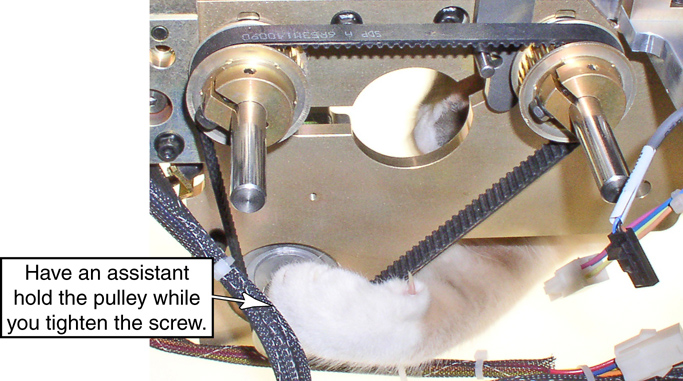

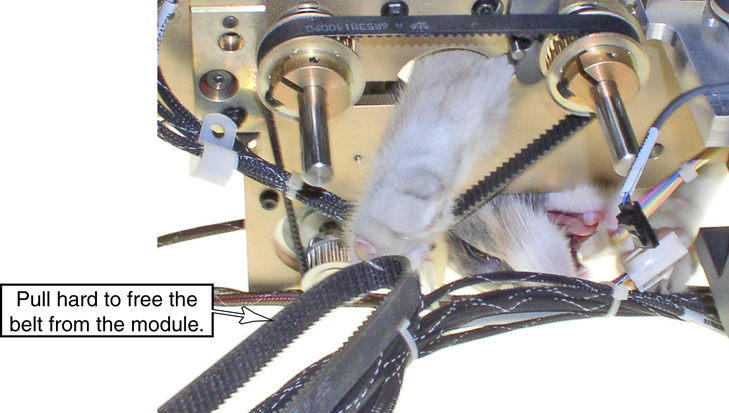

Oh, You'll get a kick out of this. I was under a tight deadline, so I took one of these $50,000 modules home over Christmas break one year. I had to reassemble it before bringing it back. Unfortunately, my cat wanted some attention from me, and did everything she could do to get in my way. Instead of fighting it, I started snapping pictures. I then re-wrote the procedures based on these pictures.

I went all the way up to the Vice President of the company to get permission, but the following pictures were released in the final Service Manual, and they remain there to this day!!! The whole machine costs between 1/2 and 1 million dollars, and these are what the Service Manual portrays.

Use the observation Port to verify that the belt is tracking correctly.

Have an assistant hold the pulley while you tighten the screw.

Don't lose your patience. Paws to reflect on your task before reassembly.