Hello,

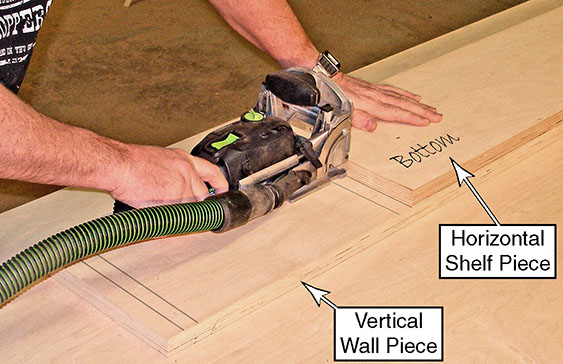

I'm new to the DF 500. Following the instructions on page 17 of Tenon Joiner Supplemental User's Manual for carcase butt joints I find that the mortice holes are far too near the edge on the horizontal shelf piece. I failed to follow the underlined instruction: "Do not use the fence for height positioning". Duh! I now understand that after fiddling about with a ruler that the height measurement is from the fence down not the base up.

So my question is. When making carcass butt joints and when you want the mortice hole in the center and you can't use the height positioning what do you do? I can get there by trial and error but I thought being Festool there may be a better way.

Thanks

I'm new to the DF 500. Following the instructions on page 17 of Tenon Joiner Supplemental User's Manual for carcase butt joints I find that the mortice holes are far too near the edge on the horizontal shelf piece. I failed to follow the underlined instruction: "Do not use the fence for height positioning". Duh! I now understand that after fiddling about with a ruler that the height measurement is from the fence down not the base up.

So my question is. When making carcass butt joints and when you want the mortice hole in the center and you can't use the height positioning what do you do? I can get there by trial and error but I thought being Festool there may be a better way.

Thanks