Doug Anders

Member

- Joined

- Jan 22, 2007

- Messages

- 29

I purchased a Domino and received it on the 9th of April. I have been looking forward to getting this unit for months...I purchased a DowelMax a couple of months ago to tide me over until the Domino arrived. I am really impressed with the accuracy and ease of use of the DowelMax and really questioned wether or not to I still needed the Domino.

Anyway, I am not having the same great results with my Domino that others are having. It seems like I have two issues with my Domino...some may be user error, but I'm not convinced yet that's all there is to it.

In the shots below it is a bit hard to see, but the DowelMax joints fit with piston like precision and there is absolutely NO elevation difference between the two pieces of MDF. The ends are also perfectly flush.

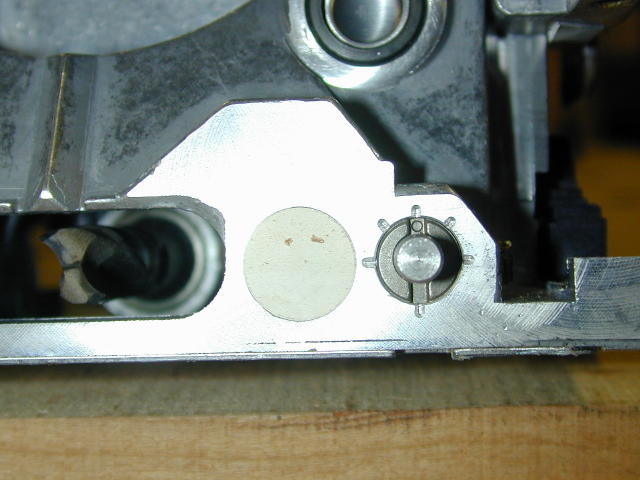

The Domino joined pieces are not perfect. There is quite a bit of elevation difference between the two pieces and it looks like when I registrer off of the indexing pins I'm not getting flush ends as I should be. Again, pictures are hard to see clearly, but my Domino joined MDF pieces the edges don't match up exactly.

After reading Rick's manual, I think I can fix the end alignment issue by adjusting the eccentric pin, but I'll still have the other issue to deal with (faces out of level). NOTE: I have not adjusted the pin yet. It looks like some adjustment was made at the factory.

Anyway, I don't think I'm being unreasonable comparing the Dowelmax to the Domino. I REALLY like the Domino dust collection and everything else, but don't know if I got a unit that need a little calibration or if my expectations are out of wack.

Anyway, I am not having the same great results with my Domino that others are having. It seems like I have two issues with my Domino...some may be user error, but I'm not convinced yet that's all there is to it.

In the shots below it is a bit hard to see, but the DowelMax joints fit with piston like precision and there is absolutely NO elevation difference between the two pieces of MDF. The ends are also perfectly flush.

The Domino joined pieces are not perfect. There is quite a bit of elevation difference between the two pieces and it looks like when I registrer off of the indexing pins I'm not getting flush ends as I should be. Again, pictures are hard to see clearly, but my Domino joined MDF pieces the edges don't match up exactly.

After reading Rick's manual, I think I can fix the end alignment issue by adjusting the eccentric pin, but I'll still have the other issue to deal with (faces out of level). NOTE: I have not adjusted the pin yet. It looks like some adjustment was made at the factory.

Anyway, I don't think I'm being unreasonable comparing the Dowelmax to the Domino. I REALLY like the Domino dust collection and everything else, but don't know if I got a unit that need a little calibration or if my expectations are out of wack.