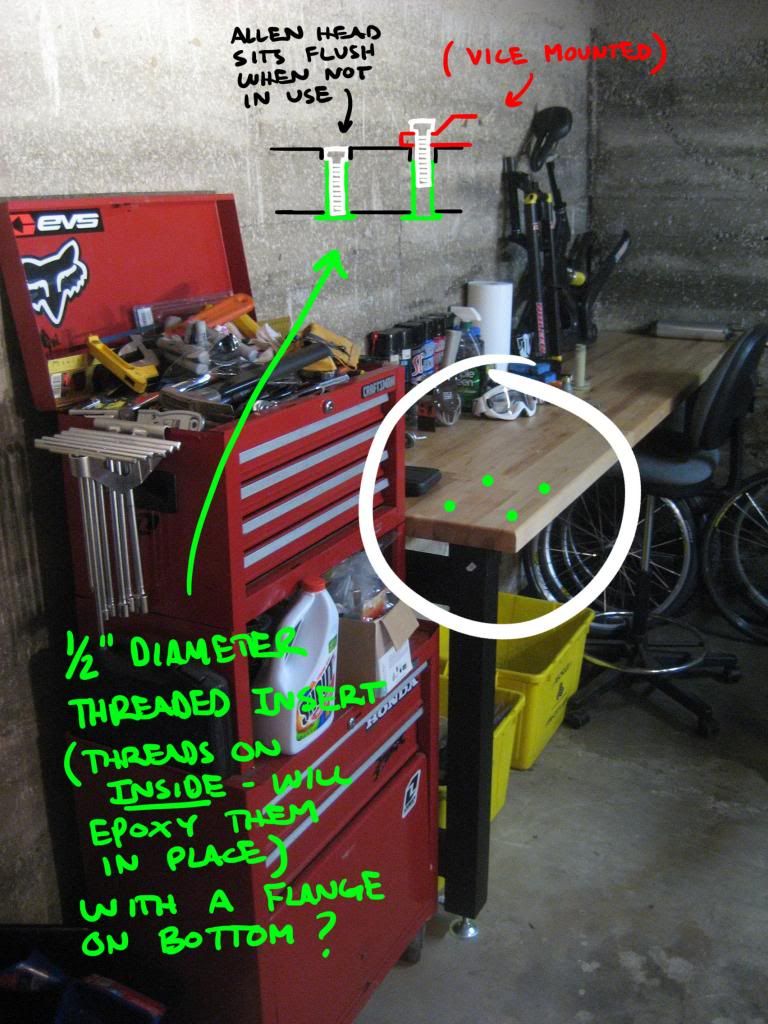

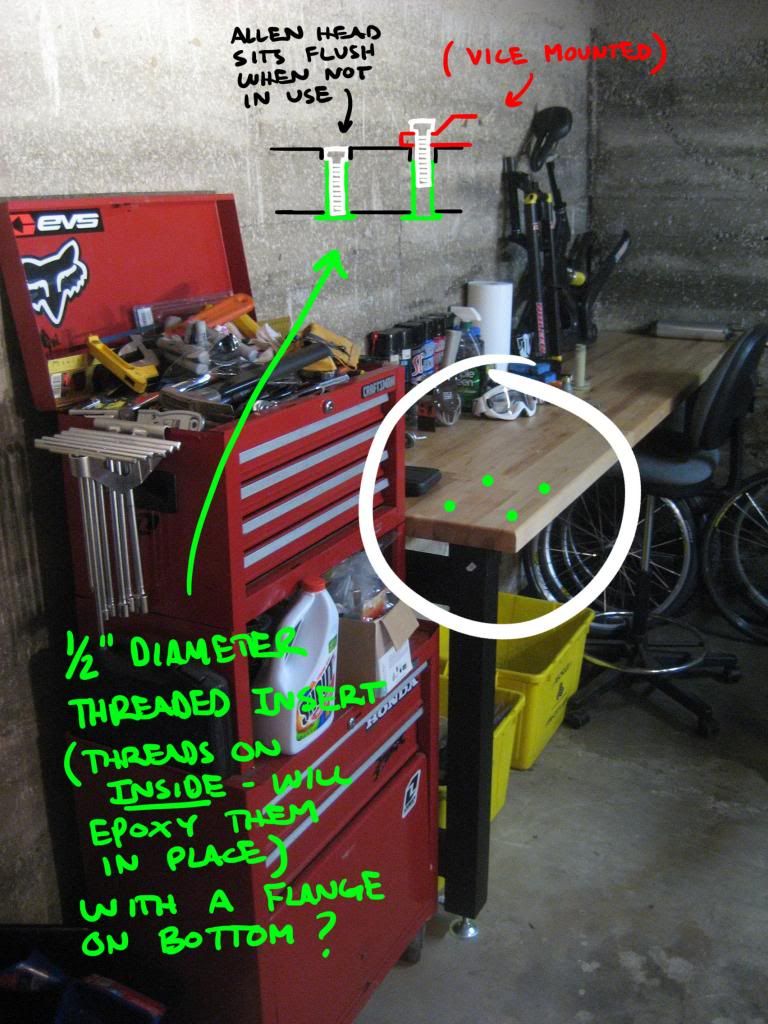

I'm looking for a clean, easily removable mounting system for my bench vice. This is my vision:

I assume hardware like that exists... not sure where to find it or how pricey it would be. Am I over-thinking this? Should I just use carriage bolts and keep them with the vice when it's not in use?

Anyone have any simply/tricky vice mounts in their shop?

I assume hardware like that exists... not sure where to find it or how pricey it would be. Am I over-thinking this? Should I just use carriage bolts and keep them with the vice when it's not in use?

Anyone have any simply/tricky vice mounts in their shop?