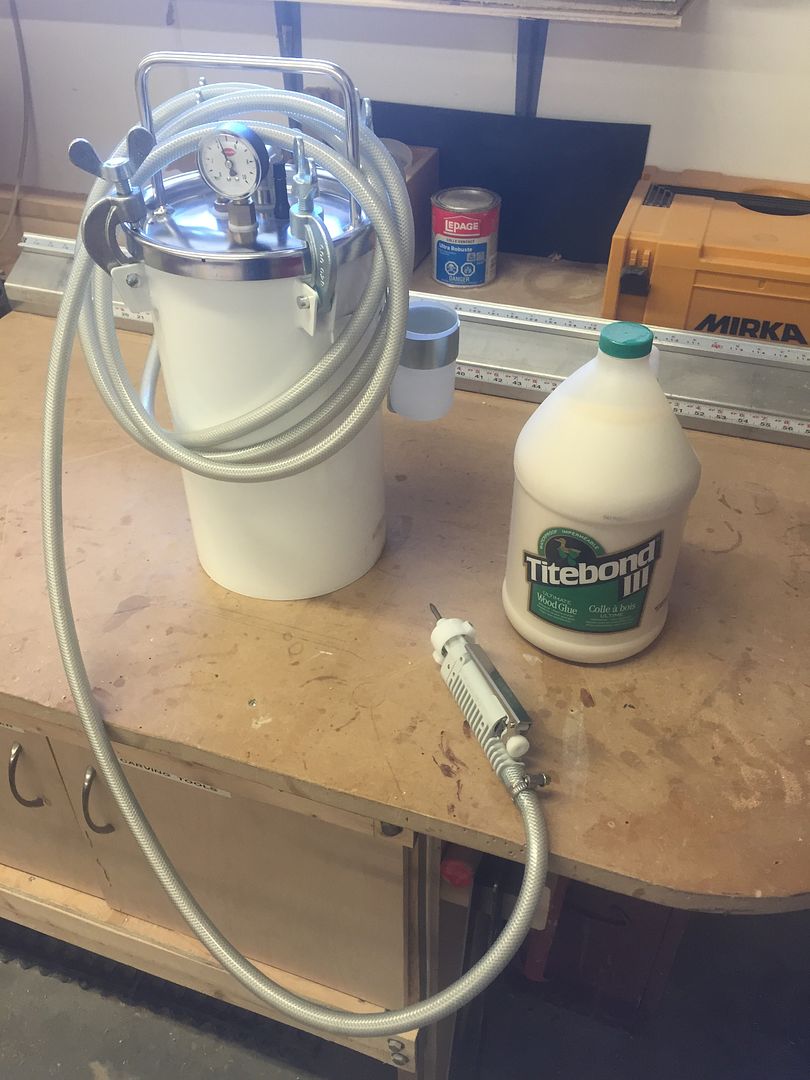

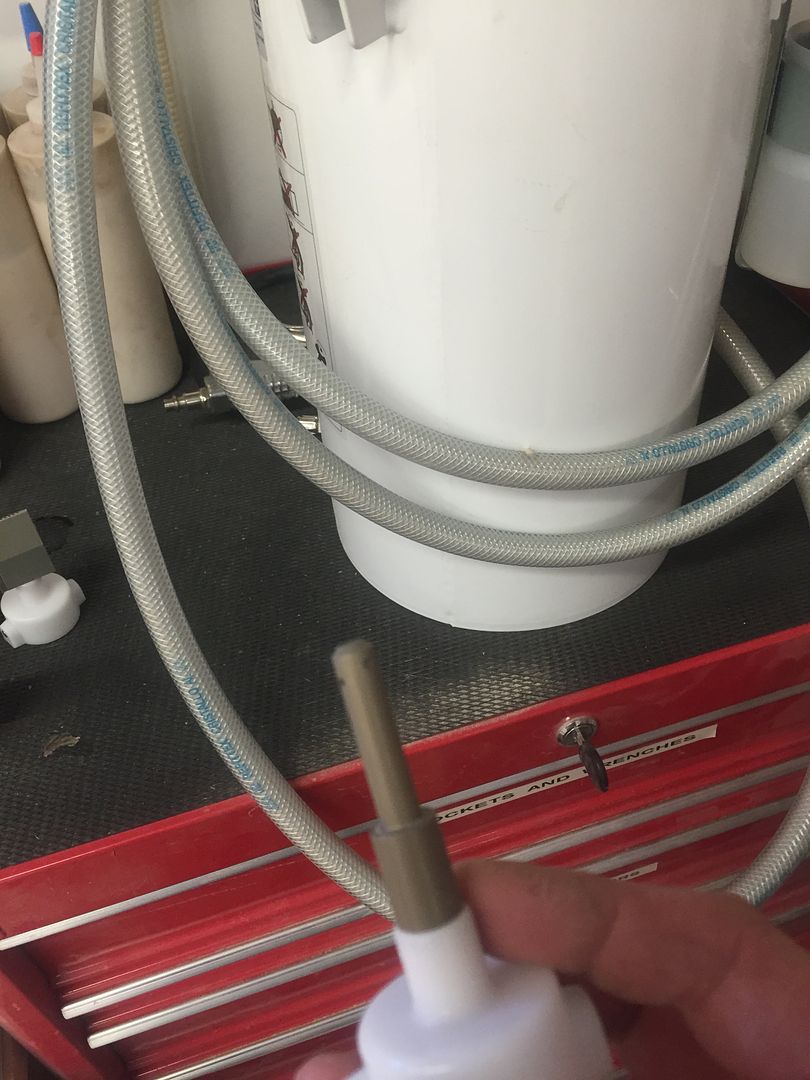

Applying glue to the Domino mortises is always a bit of a pain with a regular glue bottle. Recently I had added a Lamello LK-5 glue pot to my shop, and today I had the chance to try the 8mm dowel tip when gluing a pile of 8x50 Dominos. With the dowel tip you can quickly apply glue to the entire wall of the mortise, by squeezing the trigger while moving the head back and forth a few times while pulling it up out of the hole.

I was putting together 4 bar stool/chair seats. I cut the components out on my CNC router (and also the mortises in the arms and seat) and use the Domino machine to do the ends of the slats.

With the Lamello system, since the tips are threaded on - and I have a small machine shop within my woodworking business, I have the idea to make up some custom heads to do the more popular sizes of Domino I use (8 and 10mm) in one shot. Im going to machine the tip to fit into the mortise with 0.5mm clearance, and a series of holes around the tip. Inserting it into the mortise, squeezing the trigger and with drawing the tip should give a fast, uniform coating of glue to the entire interior of the mortise.

Ill post back my results. But this should very much speed up the gluing process.

Andrew

I was putting together 4 bar stool/chair seats. I cut the components out on my CNC router (and also the mortises in the arms and seat) and use the Domino machine to do the ends of the slats.

With the Lamello system, since the tips are threaded on - and I have a small machine shop within my woodworking business, I have the idea to make up some custom heads to do the more popular sizes of Domino I use (8 and 10mm) in one shot. Im going to machine the tip to fit into the mortise with 0.5mm clearance, and a series of holes around the tip. Inserting it into the mortise, squeezing the trigger and with drawing the tip should give a fast, uniform coating of glue to the entire interior of the mortise.

Ill post back my results. But this should very much speed up the gluing process.

Andrew