WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,205

Had to make a run to Rochester, NY and then past to Fort Plain, NY to get some stuff.

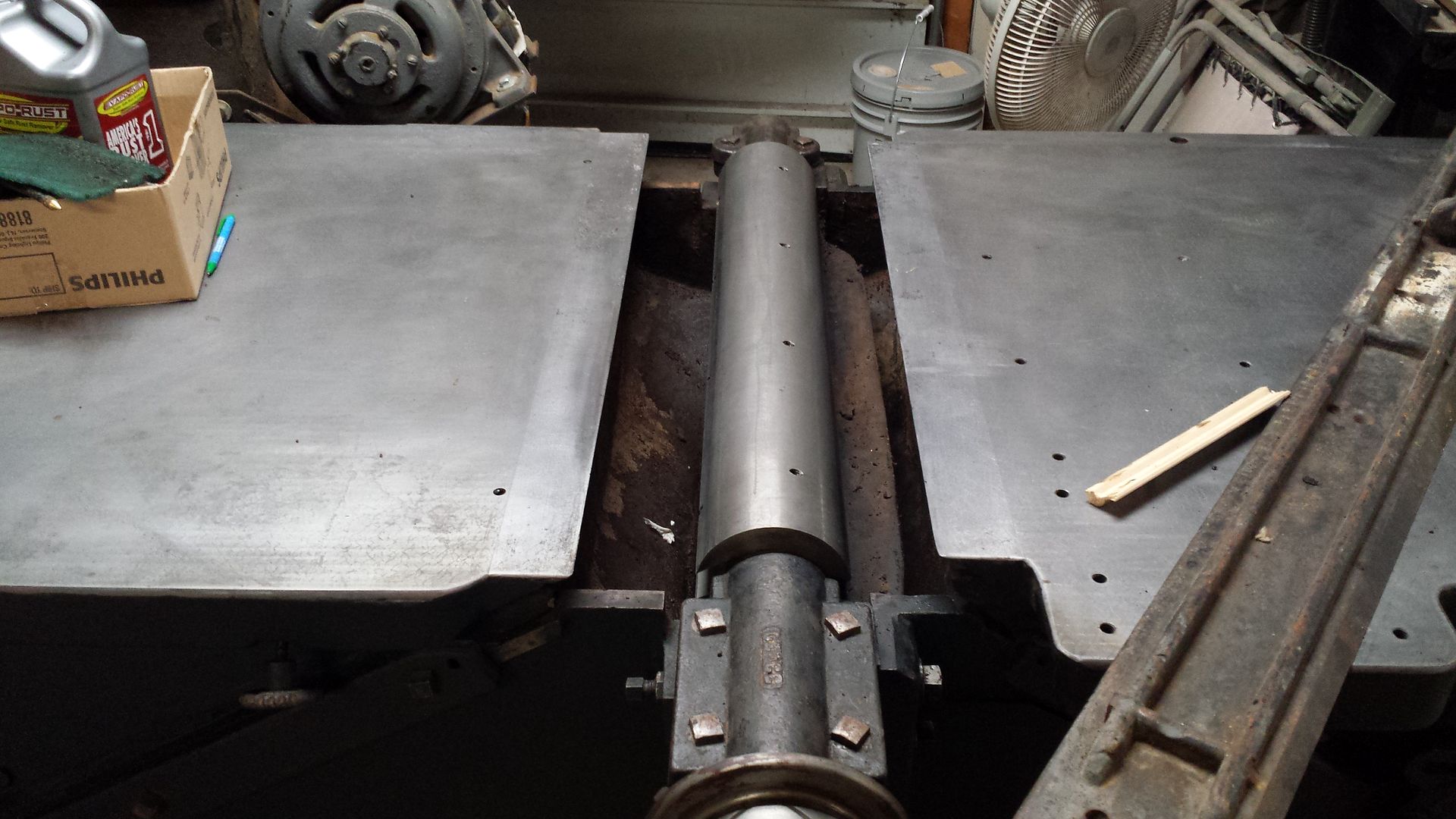

I bought the 30" American jointer in May and finally had time to go get it and then pick up some other stuff for other people.

I found the cute little 8" Wallace after I got home, we left friday night at 11pm, got home sunday at 830am.

I bought the 30" American jointer in May and finally had time to go get it and then pick up some other stuff for other people.

I found the cute little 8" Wallace after I got home, we left friday night at 11pm, got home sunday at 830am.