pingvinlakrits

Member

- Joined

- Oct 2, 2007

- Messages

- 1,093

Starting a new thread, it will get you guys going until Peter Parfitt makes that video  so feel free to be subjective and chime in but try to keep it civil.

so feel free to be subjective and chime in but try to keep it civil.

These are my initial thoughts so it does not necessarily reflect a long term user perspective but hey - gotta start somewhere.

OK DONE:

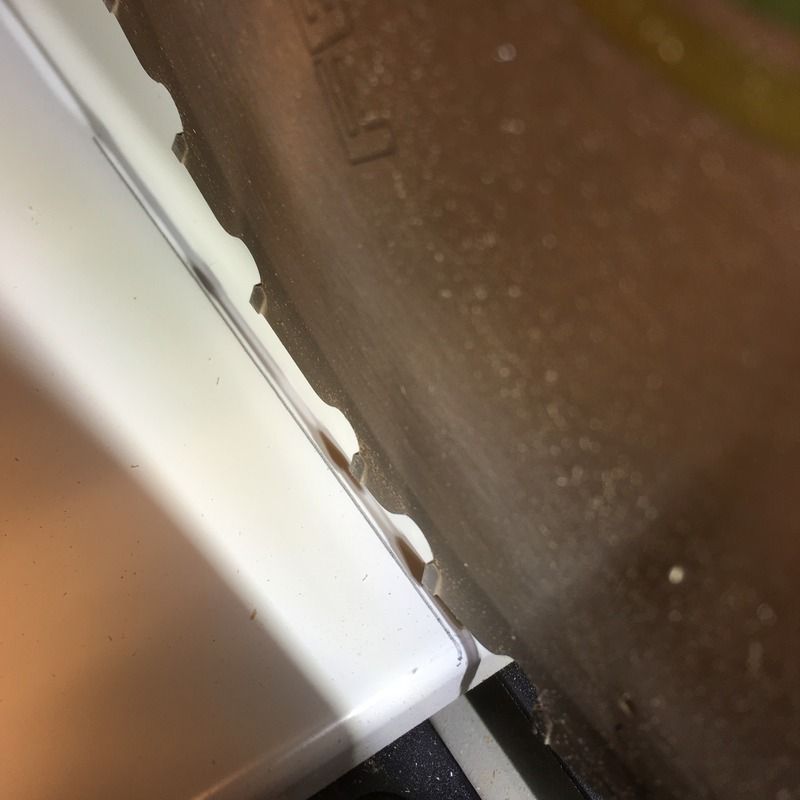

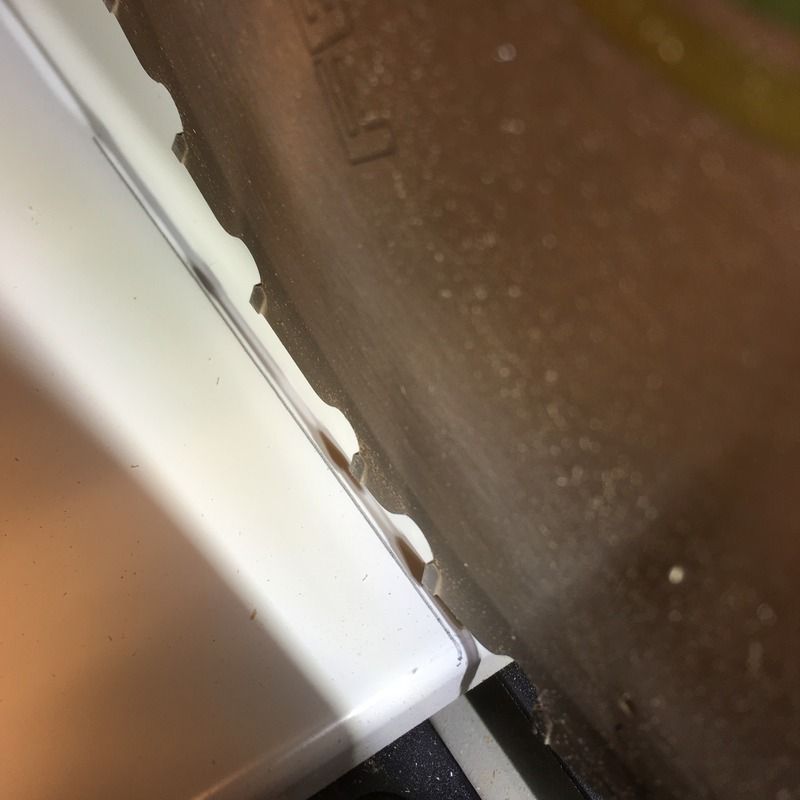

First set of images is "sneaking up on cut line with shadow line":

I must say I am not too impressed with the shadow line indication.

It neither clear nor uniform in width (of course) so you need to SPIN the blade and/or lower until you get the shadow of a tooth on your mark. You are then _very_ close to the surface and you might as well touch the surface with the blade. Does it save time? No.

If you are cutting a wider board you need to extend and lower until you are almost on the surface to register. Once there the cut is right on the money but I think it is neither more convenient or better than putting the tooth on the mark by eye sight or using a laser. [unsure]

For bevel cuts the shadow line works a little better but depending on if you are cutting on the mark or creeping up to the cut line you might overshoot. I did overshoot by a mm or a little more on the first try - even when I figured I got the shadow line right. User error of course but not intuitive, I think.

Might get used to it eventually but I think I prefer having a laser...

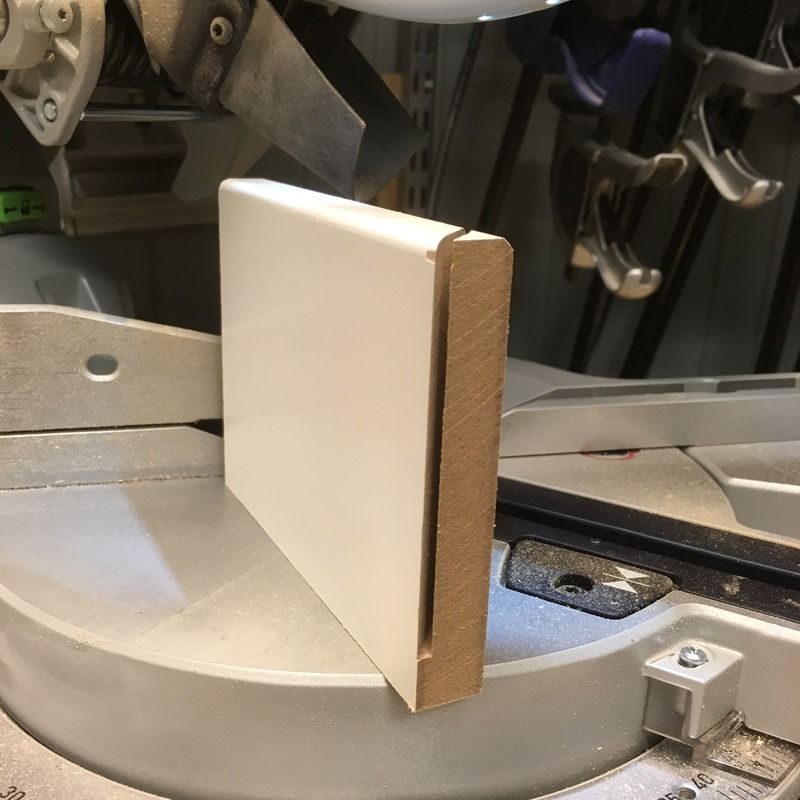

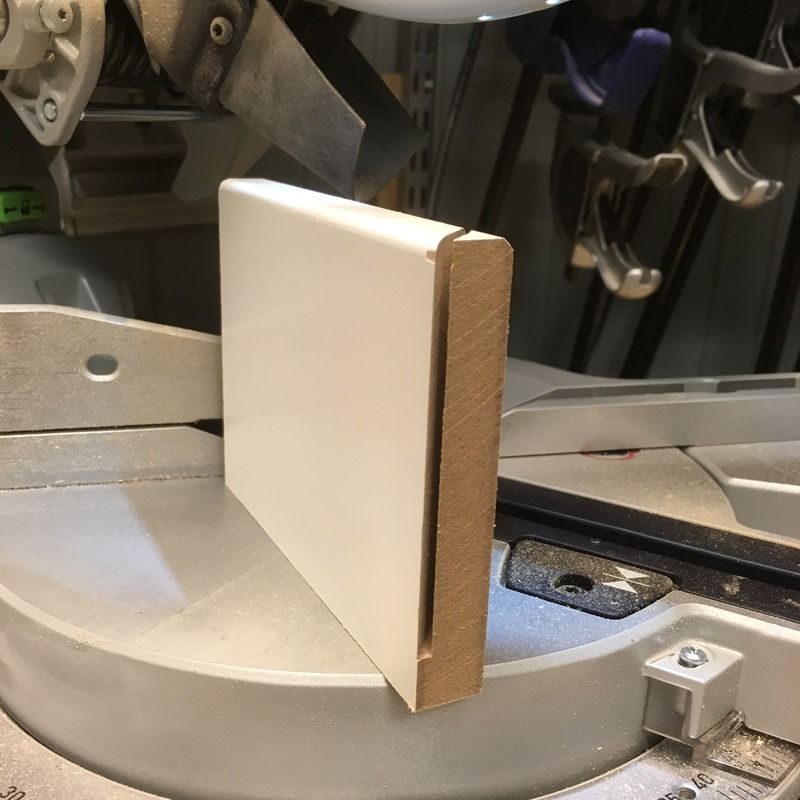

Ok, cutting narrow stock you can cut around 70mm standing the stock up. Test piece is 16x95mm mdf scrap and you can cut 16x95mm in a straight cut (barely) but in a mitre cut you get around 82mm on the 16x95mm piece, as shown on the photo. I would prefer to be able to cut standing mitres up to 95mm as it is a fairly common dimension over here but 70mm is ok.

Dust accumulated after a few test cuts:

Video on Dust Collection (TURN VOLUME DOWN [scared])

=youtu.be

Note that the dust collection through a 27mm nozzle/hose is mediocre. It does spray a lot of dust outside the chute even when allowing for the vac to start up properly. This was not impressive performance for the saw. It actually might do worse (definitely no better) than my old Makita and probably worse than my battery powered Metabo hooked up to a vac.

Video on Shadow line:=youtu.be

I do have a video which is 42 sec but it was too large to upload from my phone to my email. On that video the blade wobble is visible.

These are my initial thoughts so it does not necessarily reflect a long term user perspective but hey - gotta start somewhere.

OK DONE:

First set of images is "sneaking up on cut line with shadow line":

I must say I am not too impressed with the shadow line indication.

It neither clear nor uniform in width (of course) so you need to SPIN the blade and/or lower until you get the shadow of a tooth on your mark. You are then _very_ close to the surface and you might as well touch the surface with the blade. Does it save time? No.

If you are cutting a wider board you need to extend and lower until you are almost on the surface to register. Once there the cut is right on the money but I think it is neither more convenient or better than putting the tooth on the mark by eye sight or using a laser. [unsure]

For bevel cuts the shadow line works a little better but depending on if you are cutting on the mark or creeping up to the cut line you might overshoot. I did overshoot by a mm or a little more on the first try - even when I figured I got the shadow line right. User error of course but not intuitive, I think.

Might get used to it eventually but I think I prefer having a laser...

Ok, cutting narrow stock you can cut around 70mm standing the stock up. Test piece is 16x95mm mdf scrap and you can cut 16x95mm in a straight cut (barely) but in a mitre cut you get around 82mm on the 16x95mm piece, as shown on the photo. I would prefer to be able to cut standing mitres up to 95mm as it is a fairly common dimension over here but 70mm is ok.

Dust accumulated after a few test cuts:

Video on Dust Collection (TURN VOLUME DOWN [scared])

=youtu.be

Note that the dust collection through a 27mm nozzle/hose is mediocre. It does spray a lot of dust outside the chute even when allowing for the vac to start up properly. This was not impressive performance for the saw. It actually might do worse (definitely no better) than my old Makita and probably worse than my battery powered Metabo hooked up to a vac.

Video on Shadow line:=youtu.be

I do have a video which is 42 sec but it was too large to upload from my phone to my email. On that video the blade wobble is visible.