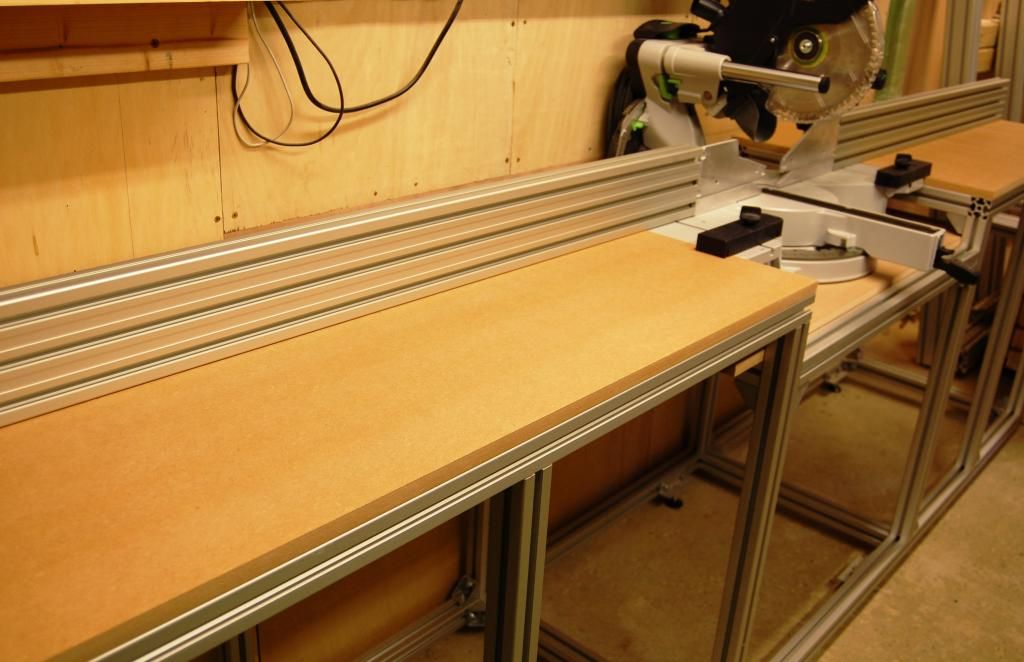

I really like the idea of a sysport with an angle towards Kapex/general miter saw and I am in the process of designing one for myself.

Did you design the depth based on the dust collector or is there some other thought behind it? How much depth do you think the kapex would need (I still do not own one...)?

For my design I am going with something a litte bit shallower (~500mm) that will fit perfectly on one of my walls and I will go for an adjustable shelf in the middle or slightly off-center for the saw itself.

Looks good!

Did you design the depth based on the dust collector or is there some other thought behind it? How much depth do you think the kapex would need (I still do not own one...)?

For my design I am going with something a litte bit shallower (~500mm) that will fit perfectly on one of my walls and I will go for an adjustable shelf in the middle or slightly off-center for the saw itself.

Looks good!