Brice_Arnold

Member

- Joined

- May 22, 2011

- Messages

- 105

Hello, I have been on the forum for about a week now. Great stuff here! I have made a couple of posts before I realized I should maybe do an introduction. I plan on sticking around.

I am the other Brice!

I would consider my self a beginner but have an absolute obsession with tools of all kinds. I am fortunate enough to do this as a hobby and have a dedicated shop for practicing my hobby.

I began my hobby in my two car garage which I had the freedom to dedicate to woodworking when we purchased our house. I basically had a clean slate to build my dream wood shop. A couple years after building my shop I got into metal working and started cramming more tools into my garage. At the same time I started a part time business manufacturing aftermarket parts for RC cars (Baja Skunkworks). Shortly there after I outgrew my shop and had to move operations to someplace with more space.

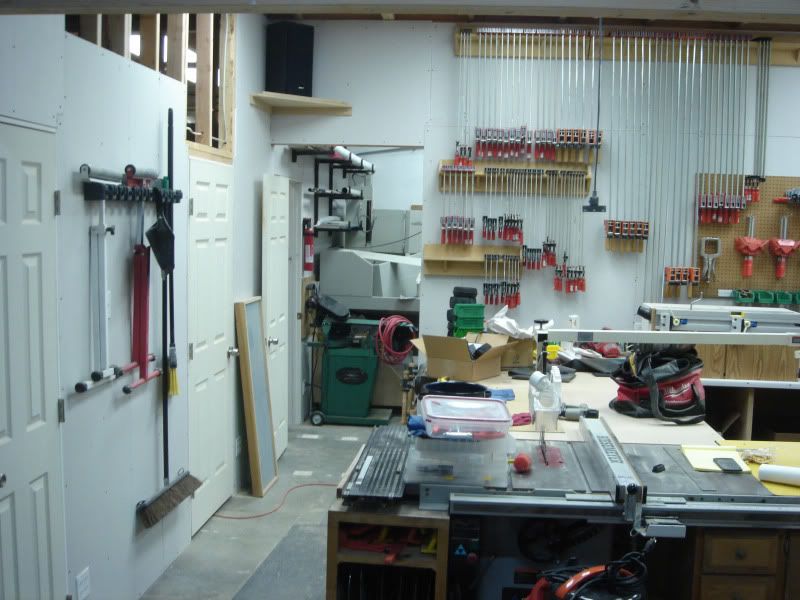

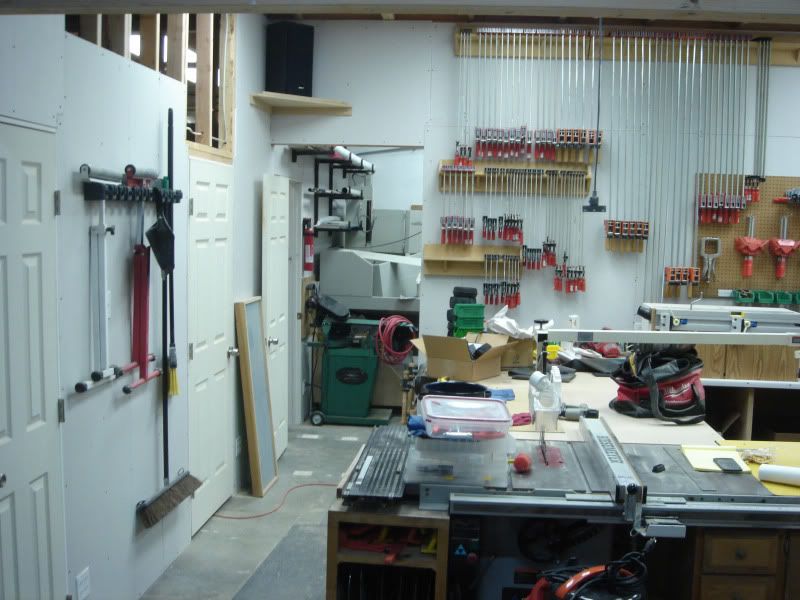

Here was my garage before the acquisition of my metal working machines and the beginning of my business.

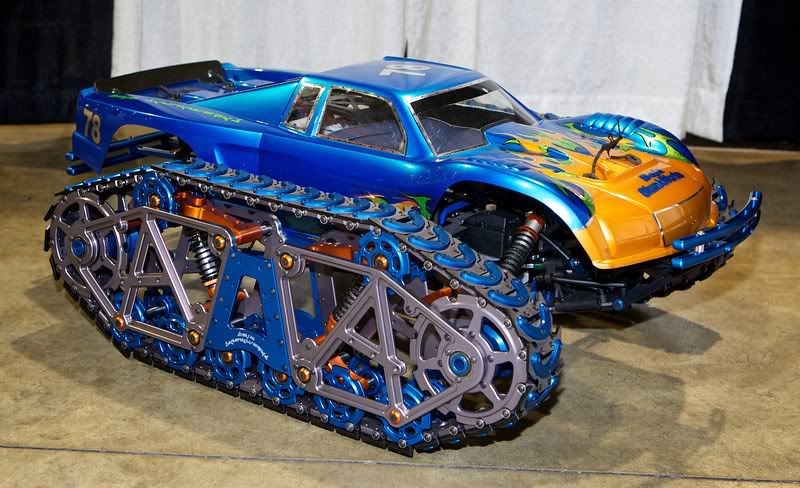

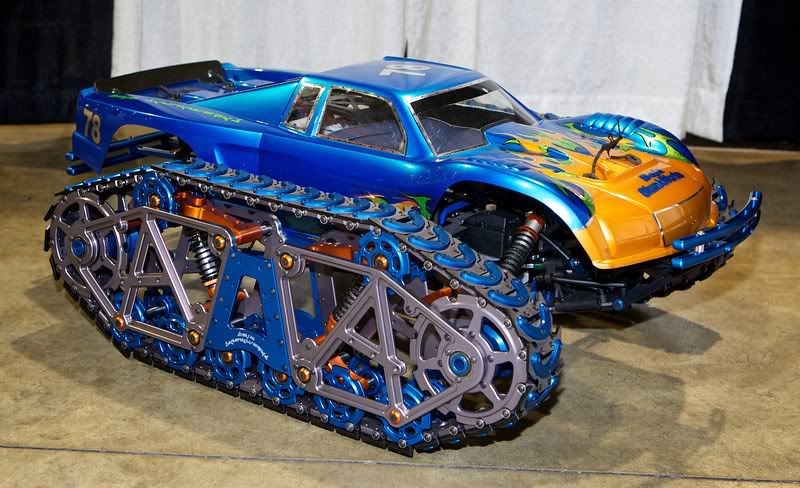

These are a couple examples of some projects that I designed and produced in my machine shop:

Scratch Built Tank Concept

Link to build from inception to completion

http://www.hpibajaforum.com/forum/showthread.php?t=79483&highlight=tracked

The Rebuild Time Laps

Baja 5T Tank: The Rebuild

Scratch Built Sandrail including Gearbox

Custom Built Two-Speed Gear System

Some Tools that I have designed and manufactured:

24mm wrench with built in bottle opener

Precision metric hex drivers from 1.5mm to 5.0mm

I have a buddy with a warehouse and he had some space to rent me so I decided to do a buildout with my dream shop version 2.0.

This has been an ongoing project for the past two years and is still on-going. For the past couple of years I have done very little woodwork. The occasional gift for a family member around the hollidays; basic cabinet carcass construction for the shop, and that's pretty much it. I have pretty much used my shop primarily for machining and running my part-time business. With all the machining that I have worked on, my woodshop has sat collecting dust, literally. This year business has been very slow. I attribute part of it to many of my products getting ripped of by Chinese clone companies and the market getting flooded with these knock-offs. If you don't appreciate quality products by now you will when you try manufacturing your own domestically. As a result, I made the decision to move on. I still do odd machining jobs which helps pay rent but I decide it was time to revitalize my woodworking. At least with this hobby I can produce something at my own pace and not have the stress or running a business, manufacturing consumer goods in the US.

I started cleaning up my shop, sharpening my tools, and getting organized.

Here are some earlier photos of my shop during the original buildout. The woodworking portion of my shop is about 18x12. I hope to do a more detailed shop tour when I get settled.

Having a dedicated shop is nice but can be a hassle. Having to drive 20 miles RT to the shop to grab a tool can be inconvenient. So I have tried to keep the bare bones tools at home which ends up being duplicates of some things that I have in the shop. I now have a collection of systainers both at home and in my shop.

I don't know if this forum will be a good or bad influence, I guess it depends on who you talk to. Every time I read one of the Burrell reviews I end up buying the tool. This month I have purchased the following festools

-Kapex KS 120

-Ro 90 (home)

-Ro 150 (2nd one for home)

-CT36 (home)

-CT Midi

-MFK 700

-CXS

-DTS 400 (home)

-LR2 kit and Rail

-Parallel Fence Kit

I almost pulled the trigger on an MFT for the house but decided to make my own. I will post this project once I get started. One of the primary feature I wanted in a portable table was a router plate. I suppose you could install one into an MFT but I have yet to see it.

In addition to doing woodworking projects in the shop I am also remodeling one of our spare bedrooms for a new arrival in the family. I have til mid July to finish the room. I picked up the CT36, DTS 400, and RO 150 for the drywall work and refinishing the floors.

My shop is almost ready to tackle my first project. I just finished installing the dust collection, tuned up my table saw and fence, Organized all the tools. The Kapex comes in next week so I will need to integrate this into my existing CMS fence. One of the things that I am looking forward to (as a tool junkie) is designing and machining tools and fixtures for woodworking and for use with the Festool system. Kind of a convergence of Bridge City Tool Works and Festool (two companies whose products and designs I greatly admire).

My other hobbies include

-Observed Trials

-Rock Climbing

-Photography

I guess that's it in a nutshell. I look forward to being an active contributor to the site.

I am the other Brice!

I would consider my self a beginner but have an absolute obsession with tools of all kinds. I am fortunate enough to do this as a hobby and have a dedicated shop for practicing my hobby.

I began my hobby in my two car garage which I had the freedom to dedicate to woodworking when we purchased our house. I basically had a clean slate to build my dream wood shop. A couple years after building my shop I got into metal working and started cramming more tools into my garage. At the same time I started a part time business manufacturing aftermarket parts for RC cars (Baja Skunkworks). Shortly there after I outgrew my shop and had to move operations to someplace with more space.

Here was my garage before the acquisition of my metal working machines and the beginning of my business.

These are a couple examples of some projects that I designed and produced in my machine shop:

Scratch Built Tank Concept

Link to build from inception to completion

http://www.hpibajaforum.com/forum/showthread.php?t=79483&highlight=tracked

The Rebuild Time Laps

Baja 5T Tank: The Rebuild

Scratch Built Sandrail including Gearbox

Custom Built Two-Speed Gear System

Some Tools that I have designed and manufactured:

24mm wrench with built in bottle opener

Precision metric hex drivers from 1.5mm to 5.0mm

I have a buddy with a warehouse and he had some space to rent me so I decided to do a buildout with my dream shop version 2.0.

This has been an ongoing project for the past two years and is still on-going. For the past couple of years I have done very little woodwork. The occasional gift for a family member around the hollidays; basic cabinet carcass construction for the shop, and that's pretty much it. I have pretty much used my shop primarily for machining and running my part-time business. With all the machining that I have worked on, my woodshop has sat collecting dust, literally. This year business has been very slow. I attribute part of it to many of my products getting ripped of by Chinese clone companies and the market getting flooded with these knock-offs. If you don't appreciate quality products by now you will when you try manufacturing your own domestically. As a result, I made the decision to move on. I still do odd machining jobs which helps pay rent but I decide it was time to revitalize my woodworking. At least with this hobby I can produce something at my own pace and not have the stress or running a business, manufacturing consumer goods in the US.

I started cleaning up my shop, sharpening my tools, and getting organized.

Here are some earlier photos of my shop during the original buildout. The woodworking portion of my shop is about 18x12. I hope to do a more detailed shop tour when I get settled.

Having a dedicated shop is nice but can be a hassle. Having to drive 20 miles RT to the shop to grab a tool can be inconvenient. So I have tried to keep the bare bones tools at home which ends up being duplicates of some things that I have in the shop. I now have a collection of systainers both at home and in my shop.

I don't know if this forum will be a good or bad influence, I guess it depends on who you talk to. Every time I read one of the Burrell reviews I end up buying the tool. This month I have purchased the following festools

-Kapex KS 120

-Ro 90 (home)

-Ro 150 (2nd one for home)

-CT36 (home)

-CT Midi

-MFK 700

-CXS

-DTS 400 (home)

-LR2 kit and Rail

-Parallel Fence Kit

I almost pulled the trigger on an MFT for the house but decided to make my own. I will post this project once I get started. One of the primary feature I wanted in a portable table was a router plate. I suppose you could install one into an MFT but I have yet to see it.

In addition to doing woodworking projects in the shop I am also remodeling one of our spare bedrooms for a new arrival in the family. I have til mid July to finish the room. I picked up the CT36, DTS 400, and RO 150 for the drywall work and refinishing the floors.

My shop is almost ready to tackle my first project. I just finished installing the dust collection, tuned up my table saw and fence, Organized all the tools. The Kapex comes in next week so I will need to integrate this into my existing CMS fence. One of the things that I am looking forward to (as a tool junkie) is designing and machining tools and fixtures for woodworking and for use with the Festool system. Kind of a convergence of Bridge City Tool Works and Festool (two companies whose products and designs I greatly admire).

My other hobbies include

-Observed Trials

-Rock Climbing

-Photography

I guess that's it in a nutshell. I look forward to being an active contributor to the site.